Bucket elevator with automatic cleaning function

A bucket elevator and automatic cleaning technology, applied in the direction of conveyors, cleaning devices, conveyor objects, etc., can solve the problems of high material loss rate, difficult to clean the side wall of the chamber above the discharge port, etc., and reach the clean area Large range, easy to grasp and handle, and reduce the effect of loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

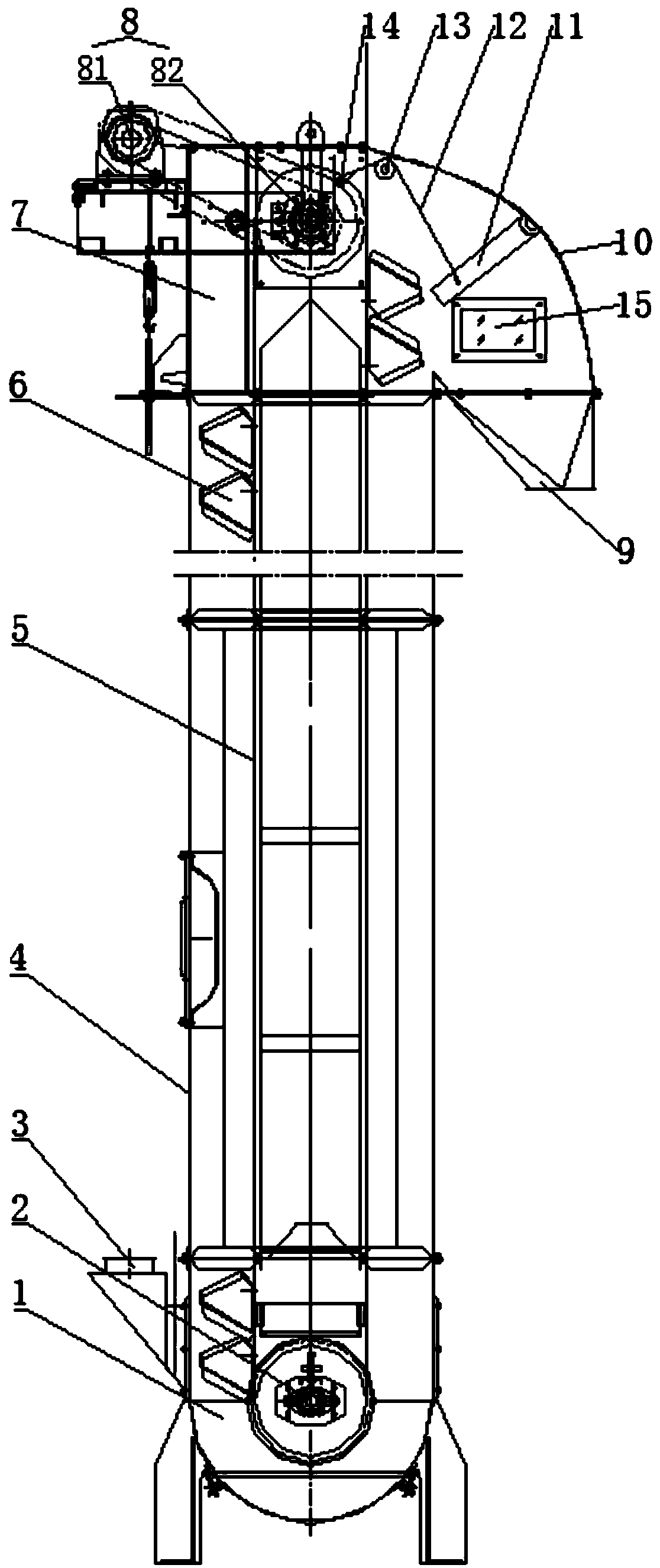

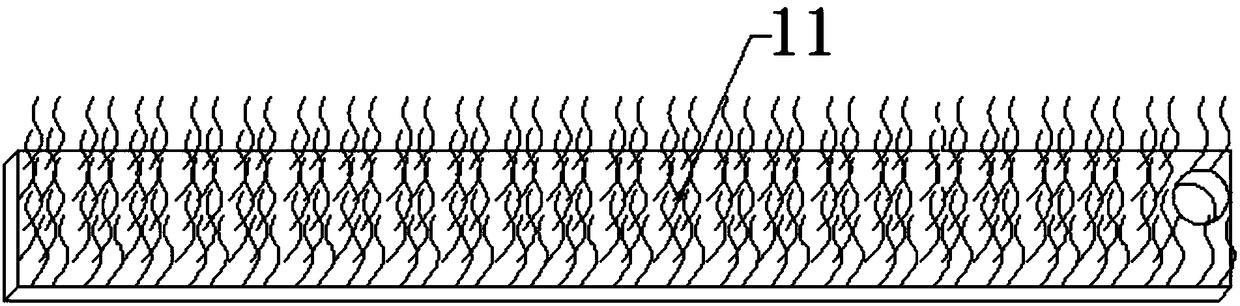

[0026] A bucket elevator with automatic cleaning function, including a machine base, a machine head, the machine base and the machine head are connected through a machine barrel, a feed port is opened on the side of the machine base, and a tail wheel is also provided in the machine base. There is a transmission device inside the machine head, the transmission device and the tail wheel are connected by a bucket belt, and a plurality of buckets are evenly arranged on the bucket belt, and a buffer room connected with the machine head is also provided on one side of the machine head , the bottom of the buffer chamber is provided with a discharge port, the side wall of the buffer chamber is hinged with a cleaning brush, the head wheel of the transmission device is eccentrically provided with a rotating nail, and the rotating nail is connected to the cleaning brush through a connecting rope away from the hinge point of the cleaning brush and the side wall of the buffer chamber one en...

Embodiment 2

[0028] On the basis of Embodiment 1, the side wall of the buffer chamber is also provided with a running wheel between the cleaning brush and the rotating nail. The height of the running wheel in the vertical direction is higher than that of the cleaning brush and the rotating nail. On the nail and the cleaning brush, the connecting rope is arranged on the running wheel. By setting the runner, the working area of the cleaning brush can be further increased, thereby reducing the material loss rate; in addition, the runner can also control the movement of the connecting rope in the same plane as possible, that is, the cleaning brush is always close to the buffer during the rotation The state of the side wall of the chamber ensures cleaning efficiency and overall stability.

Embodiment 3

[0030] On the basis of the above embodiment, the side of the buffer chamber is a quarter circle, and the cleaning brush is hinged at the middle of the arc surface of the buffer chamber. By setting the side of the buffer chamber as a quarter circle, the cleaning brush is hinged in the middle of the arc surface of the side wall of the buffer chamber, which ensures a large cleaning area of the cleaning brush and reduces the material loss rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com