Semi-automatic paper bag bottom pasting machine

A bottom paste machine, semi-automatic technology, applied in papermaking, bag making, paper/cardboard containers, etc., can solve the problems of poor bottom paste quality of paper bags, affecting the appearance, difficult to popularize and use in small and medium-sized enterprises, etc. Guaranteed production quality and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

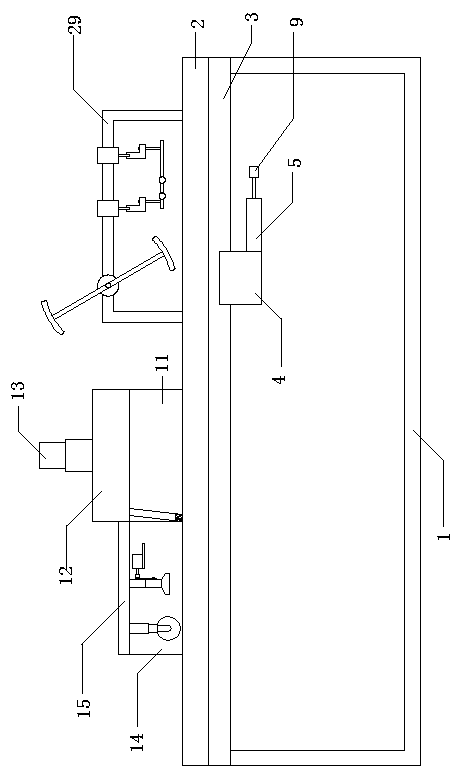

[0022] Such as figure 1 Shown is a schematic structural diagram of the present invention. The present invention is a semi-automatic paper bag bottom paste machine, including a paper bag feeding mechanism, and the paper bag feed mechanism is sequentially installed with a bag bottom unfolding mechanism, a glue spraying mechanism, and a bottom paste according to the order in which the paper bag travels. compaction mechanism.

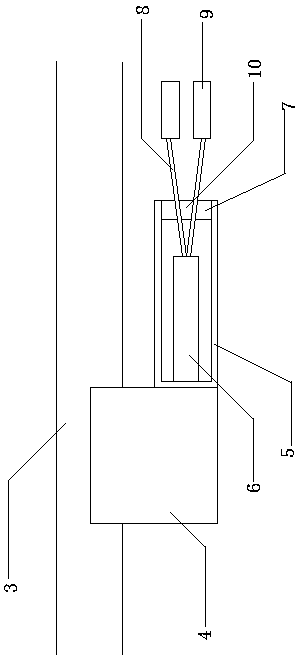

[0023] Such as figure 2 , the paper bag feeding mechanism includes a feeding base 1, a feeding support plate 2, and a feeding clamping mechanism. The inner side of the support plate 2 is uniformly and continuously installed with a feed whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com