A multifunctional cutting machine

A cutting machine and multi-functional technology, applied in metal processing, etc., can solve the problems of high labor consumption and low work efficiency, and achieve the effects of high work efficiency, improved efficiency, and convenient cleaning and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

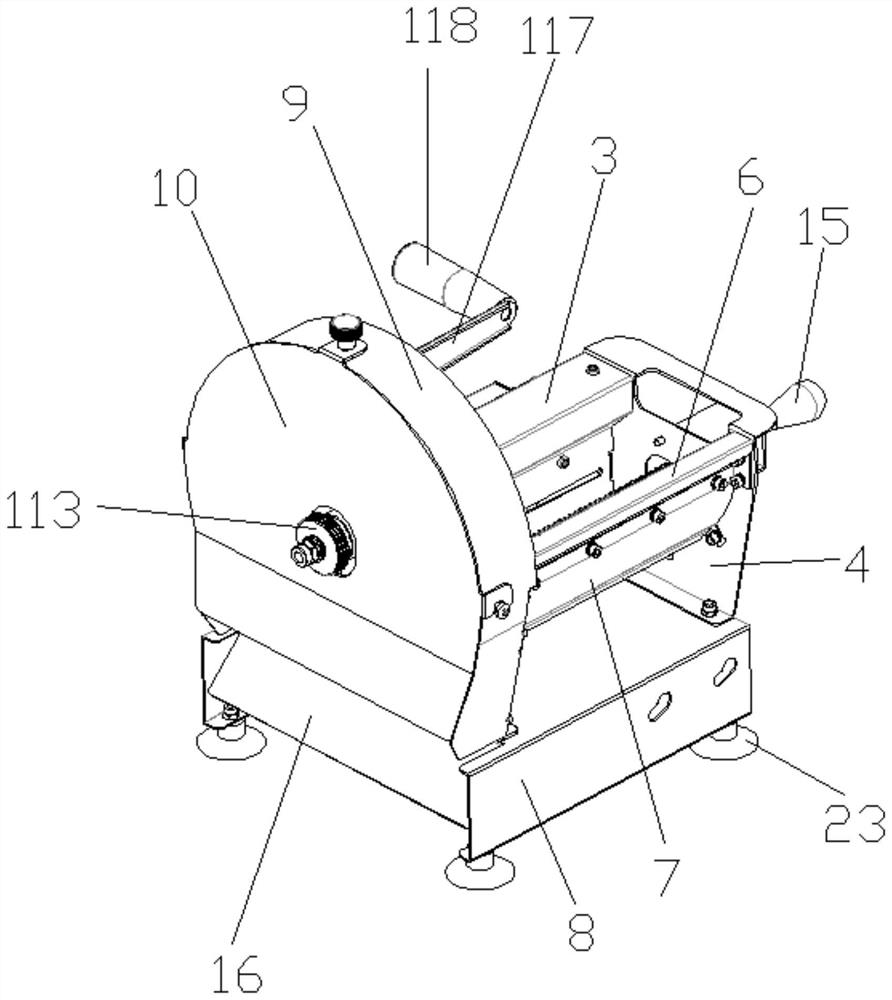

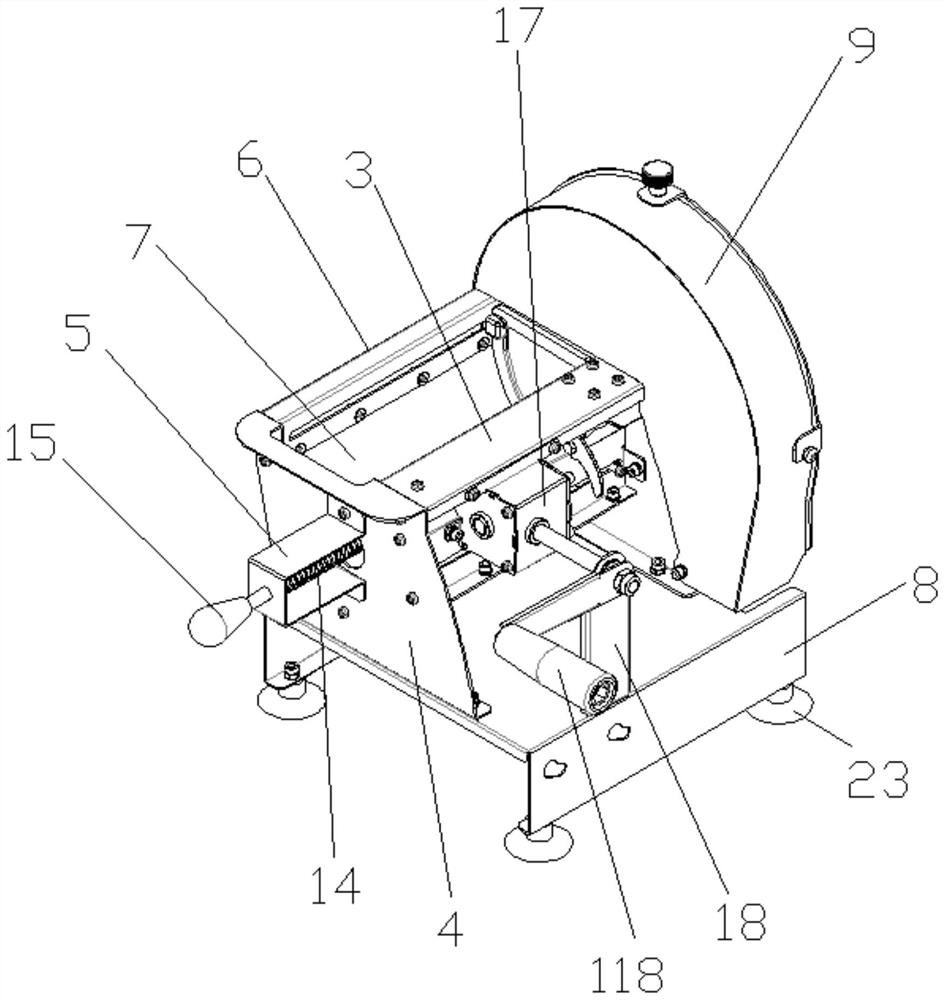

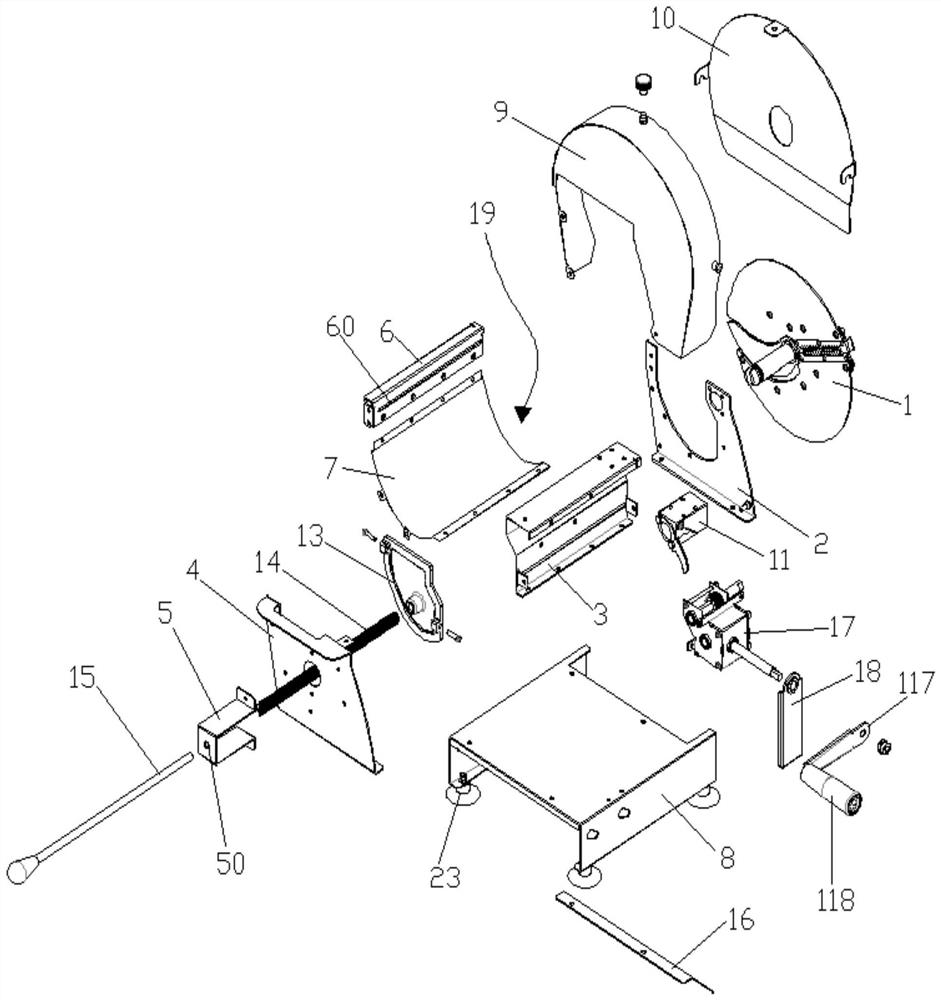

[0057] Embodiment one: if Figure 1 to Figure 17 The first embodiment of a multifunctional cutting machine shown includes a mounting frame, a cutter head 1, a cutting knife 103 and a governor 17, and the mounting frame includes a base 8 and an axle seat plate 3, and the axle seat The plate 3 is connected to the upper surface of the base 8, and the outer side of the shaft seat plate 3 is connected with a speed governor 17, and the two sides of the speed governor 17 extend out a shaft body, and the shaft body rotates freely, and the shaft body on one side is The output shaft 201, the shaft body on the other side is the input shaft 213, the middle point of the side of the cutterhead 1 is pierced with a rotating shaft 101, and the output shaft 201 of the governor 17 is connected to the rotating shaft 101 of the cutterhead 1 through transmission. A shaft seat assembly 11 is sleeved between the output shaft 201 and the rotating shaft 101 , and the cutting knife 103 is embedded in th...

Embodiment 2

[0084] Embodiment two: if Figure 1 to Figure 7 and Figure 17 to Figure 20 Embodiment 2 shown: In this embodiment 2, the cutter head 1 includes a cutter head panel 302, a cutter head middle plate 303, a cutter head rear plate 304, a fixing seat 110, a main shaft 111, an adjustment knob 113, a handle connection Rod 117, handle 118, handle shaft 119;

[0085] One end of the main shaft 111 passes through the fixed seat 110, the cutter head rear plate 304, the cutter head middle plate 303, the cutter head panel 302 and the cutting knife 103 in turn, and is connected with the rotating shaft 101. The shape of the cutting knife 103 is "S" ;

[0086] The other end of the main shaft 111 away from the fixing seat 110 is sequentially provided with an adjusting knob 113 and a handle connecting rod 117, which are connected and fixed by nuts;

[0087] A handle 118 is connected to the end of the handle connecting rod 117 away from the adjustment knob 113, and a handle shaft 119 is pierce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com