Method for using pressure riveting positioning tool for headless rivets

A riveting and tool technology, which is applied in the field of pressure riveting riveting positioning tools for headless rivets, and can solve the problems of large size and poor matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

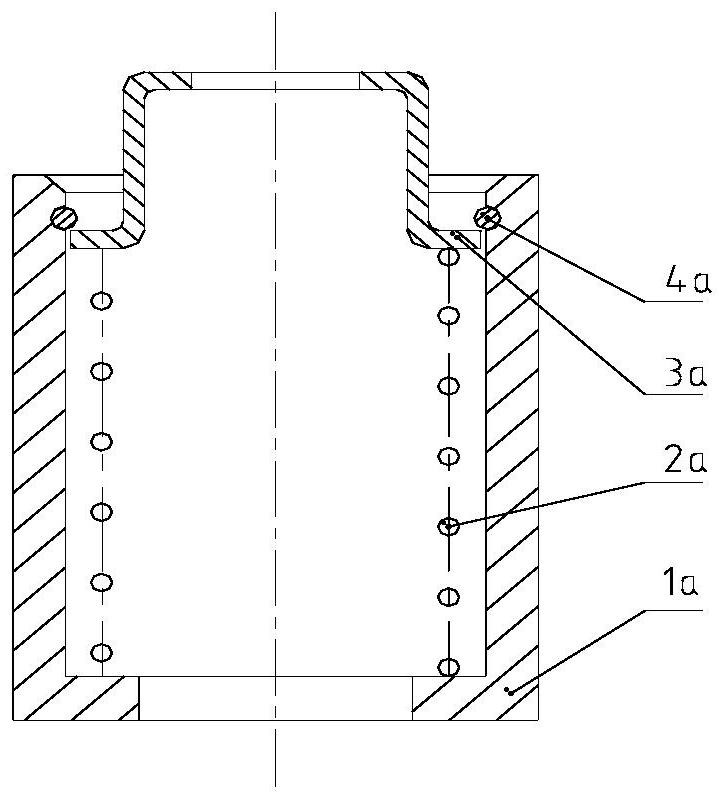

[0069] Such as figure 1 As shown, a pressure riveting positioning tool for headless rivets includes a base A1a, a spring A2a, a spring seat A3a and a retaining spring A4a.

[0070] A spring A2a is installed inside the base A1a, and the outer diameter of the spring A2a is smaller than the inner diameter of the base A1a. A spring seat A3a is installed on the inner wall of the upper part of the base A1a, and the spring seat A3a is positioned by a snap ring A4a. Both ends of the spring A2a are respectively limited by the bottom end of the base A1a and the spring seat A3a.

[0071] Such as image 3 As shown, the spring seats A3a of the same two positioning tools are placed opposite to each other when in use.

Embodiment 2

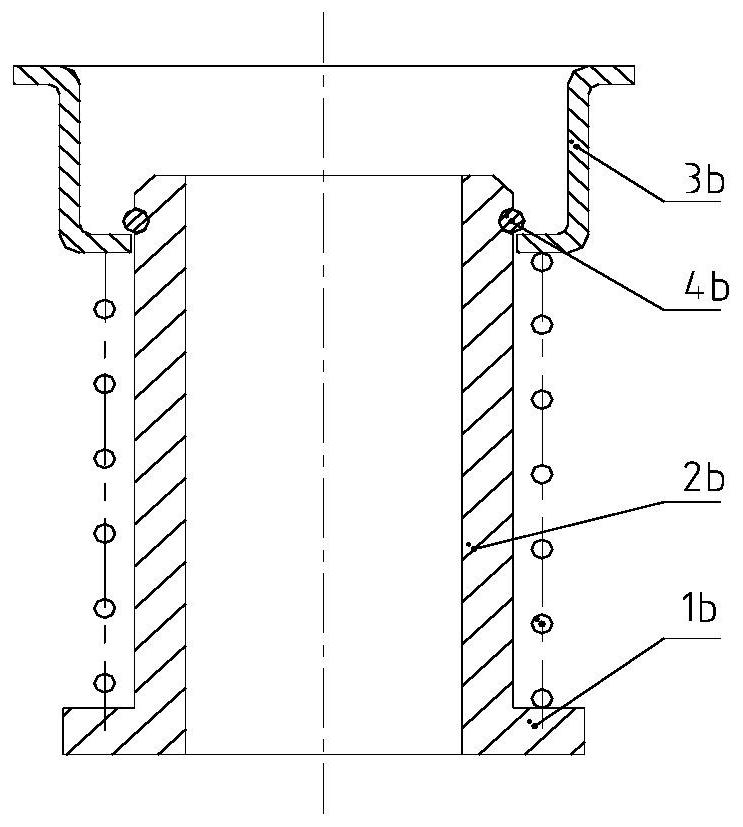

[0073] Such as figure 2 As shown, a pressure riveting positioning tool for headless rivets includes a base B1b, a spring B2b, a spring seat B3b and a retaining spring B4b.

[0074] A spring B2b is installed outside the base B1b, and the inner diameter of the spring B2b is larger than the outer diameter of the base B1b. A spring seat B3b is installed on the outer wall of the upper part of the base B1b, and the spring seat B3b is positioned by a snap spring B4b. Both ends of the spring B2b are respectively limited by the bottom end of the base B1b and the spring seat B3b.

[0075] Such as Figure 4 As shown, the spring seats B3b of the same two positioning tools are placed opposite to each other when in use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com