Aviation engine blade forging method and die

A technology of aero-engines and blades, which is applied in the direction of engine components, manufacturing tools, mechanical equipment, etc., can solve the problems of high production cost, complicated process, and large number of tooling, and achieve low production cost, simple process route, and air isolation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

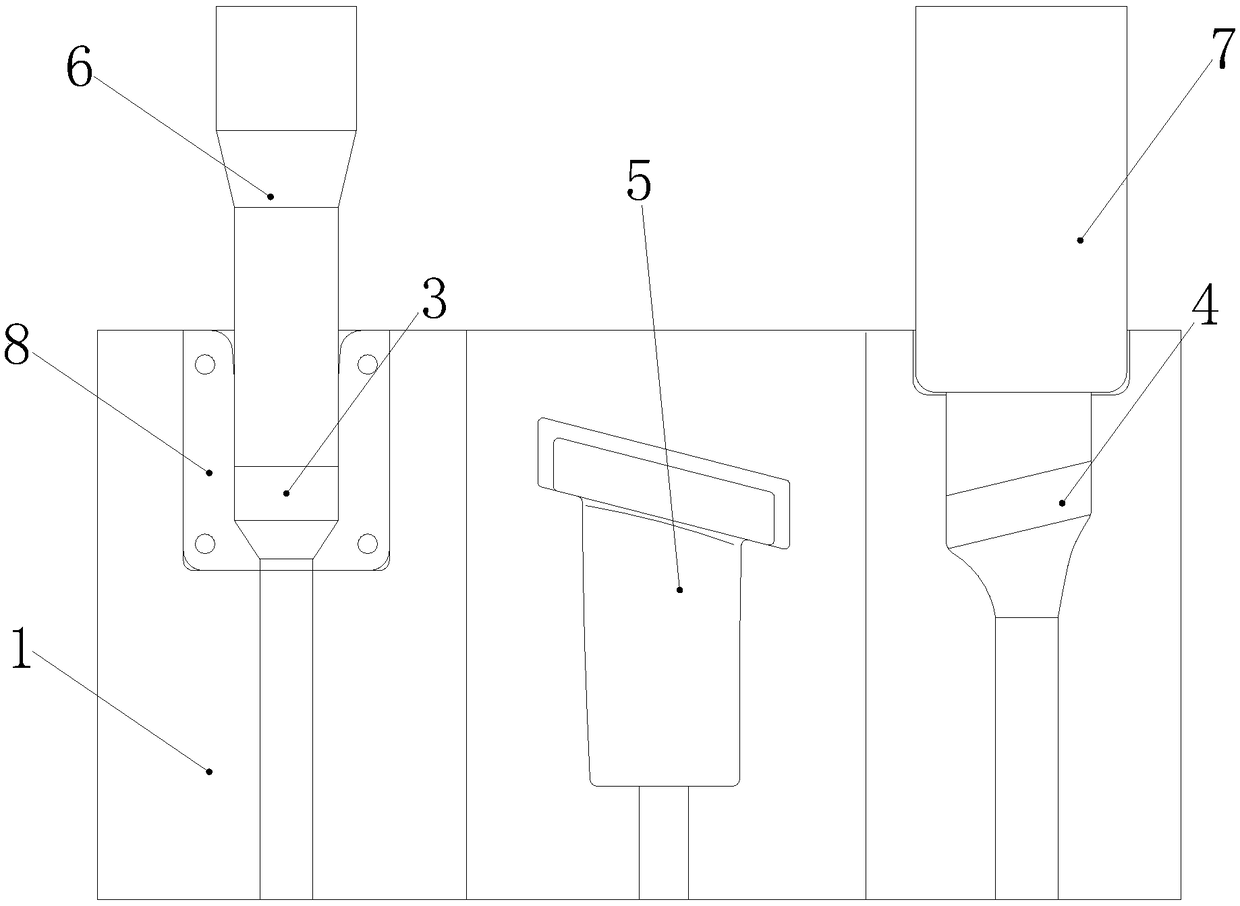

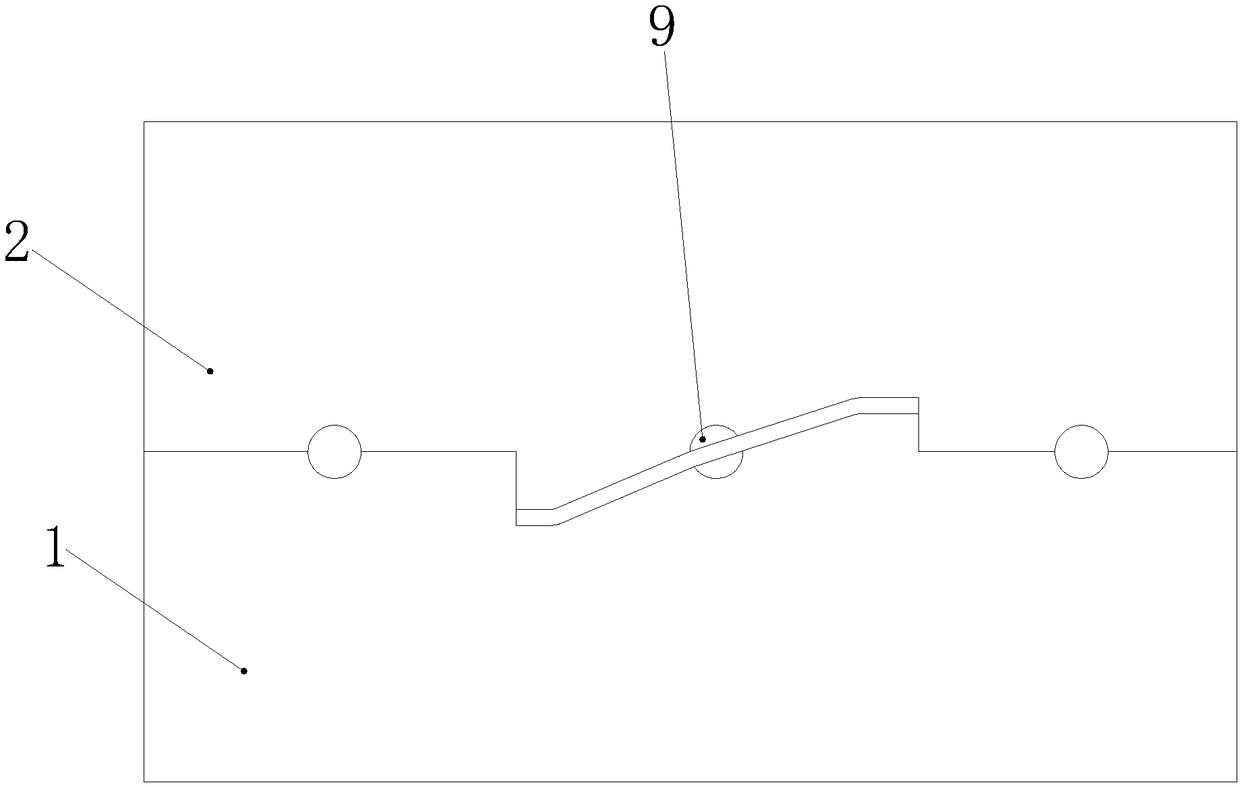

[0025] figure 1 It is a schematic flow chart of a forging method for an aeroengine blade according to a preferred embodiment of the present invention; figure 2 Is one of the schematic diagrams of the die for forging aeroengine blades according to the preferred embodiment of the present invention; image 3 It is the second schematic diagram of the die for forging aeroengine blades according to the preferred embodiment of the present invention.

[0026] Such as figure 1 As shown, the aeroengine blade forging method of this embodiment includes the following steps: a. blank blanking; b. spray glass lubricant on the surface of blank blank; c. heat blank blank to above the recrystallization tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com