Sandwich organic/inorganic hybridized microspheres and preparation method thereof

A sandwich type, hybrid microsphere technology, applied in the field of new materials, to achieve the effect of uniform size, enhanced bonding firmness, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

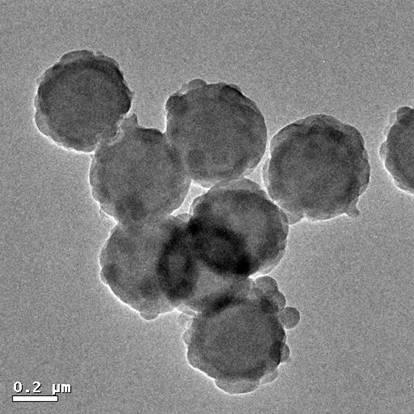

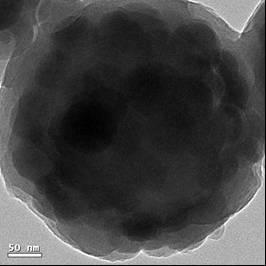

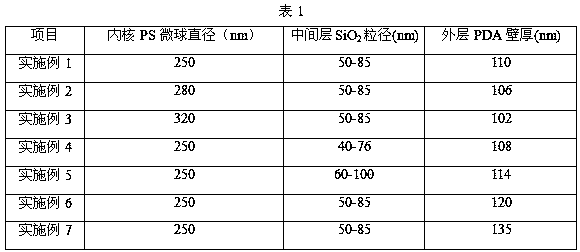

[0022] 1) Preparation of soft-core / hard-shell PS microspheres: Measure 8mL styrene, add it dropwise to 120mL deionized water, blow in high-purity nitrogen gas and stir for 30min, heat to 70°C, then add 14mL containing 0.16g persulfuric acid Potassium deionized aqueous solution was used as an initiator, stirred at 70°C for 4 h, and then 1.8 mL of divinylbenzene was added to the above system to continue the reaction for 24 h to obtain soft-core / hard-shell PS microspheres with a diameter of 250 nm.

[0023] 2) Raspberry-like PS / SiO 2 Preparation of composite microspheres: Take 0.5 g of PS microspheres prepared in step 1) and ultrasonically disperse them in 160 mL of ethanol, then add 1 mL of tetraethyl orthosilicate to the above solution and stir for 30 min, then add 20 mL of ammonia water dropwise and continue stirring After 10h, a raspberry-like PS / SiO will be obtained 2 The composite microsphere emulsion is dried after centrifugation.

[0024] 3) Sandwich type PS / SiO 2 / PDA...

Embodiment 2

[0027] 1) Preparation of soft-core / hard-shell polystyrene (PS) microspheres: Measure 8 mL of styrene, add it dropwise to 120 mL of deionized water, blow in high-purity nitrogen gas and stir for 30 minutes, heat to 70°C, and then add 14 mL A deionized aqueous solution containing 0.12 g of potassium persulfate was used as an initiator, stirred at 70°C for 4 h, and then 1.8 mL of divinylbenzene was added to the above system to continue the reaction for 24 h to obtain a soft-core / hard-shell PS with a diameter of 280 nm. Microspheres.

[0028] 2) Raspberry-like PS / SiO 2 Preparation of composite microspheres: according to Example 1.

[0029] 3) Sandwich type PS / SiO 2 Preparation of / PDA composite microspheres: Carry out according to Example 1.

Embodiment 3

[0031] 1) Preparation of soft-core / hard-shell polystyrene (PS) microspheres: Measure 8 mL of styrene, add it dropwise to 120 mL of deionized water, blow in high-purity nitrogen gas and stir for 30 minutes, heat to 70°C, and then add 14 mL A deionized aqueous solution containing 0.08 g of potassium persulfate was used as an initiator, stirred at 70°C for 4 h, and then 1.8 mL of divinylbenzene was added to the above system to continue the reaction for 24 h to obtain a soft-core / hard-shell PS with a diameter of 320 nm. Microspheres.

[0032] 2) Preparation of PS / PDA composite microspheres: according to Example 1.

[0033] 3) Sandwich type PS / SiO 2 Preparation of / PDA composite microspheres: Carry out according to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com