High-stability rolling brush device

A high-stability, rolling brush technology, applied in brushes, brush bodies, bristle brackets, etc., can solve the problems of high assembly difficulty, low transmission efficiency, and no independent separation, so as to achieve a simple and clear overall structure and improve transmission efficiency. And, to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

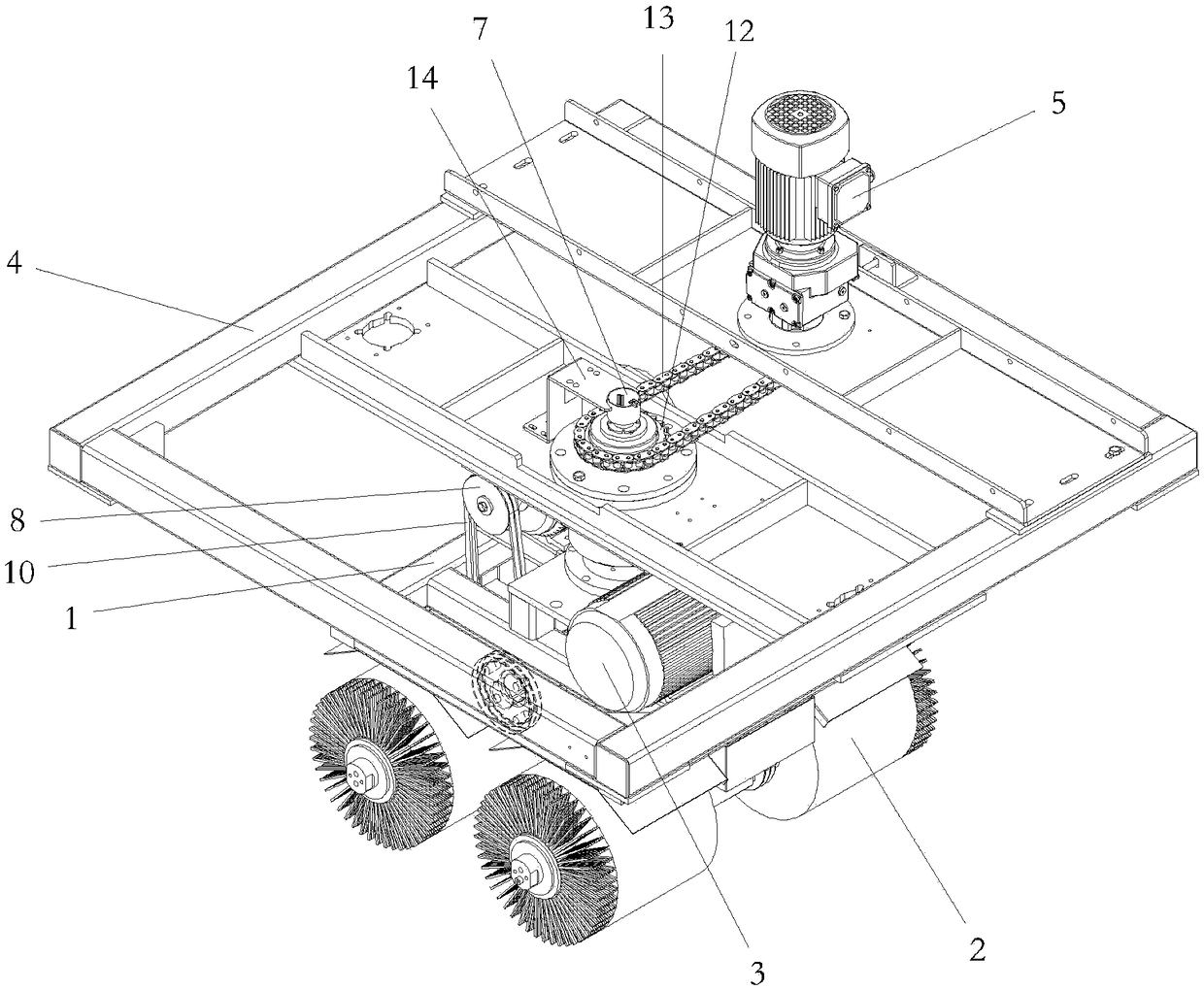

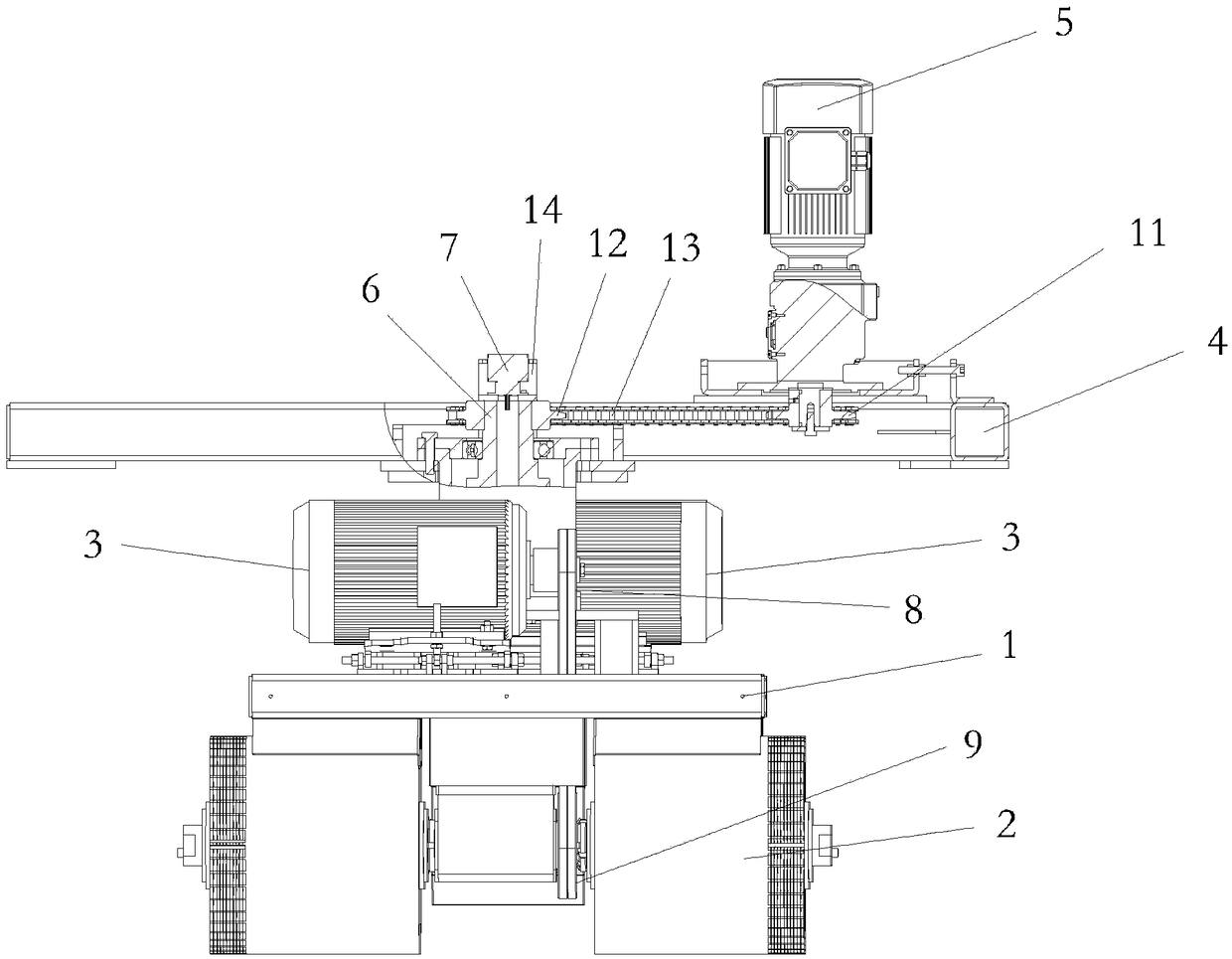

[0020] Shown in conjunction with the accompanying drawings is a specific embodiment of a high-stability rolling brush device of the present invention, including a first bracket 1 and two rolling brushes 2 arranged on the first bracket 1, and on the first bracket 1 Two rotation drive motors 3 are provided, and each rotation drive motor 3 corresponds to each roller brush 2 one by one, and the two rotation drive motors 3 are respectively connected to drive the corresponding roller brush 2 to rotate by rotation transmission mechanism.

[0021] The rotation transmission mechanism includes a driving pulley 8 mounted on the output shaft of the rotation drive motor 3, a driven pulley 9 mounted on the roller brush 2, and a belt connecting the driving pulley 8 and the driven pulley 9. drive belt 10. Since the self-rotation drive motor 3 drives the roller brush 2 to rotate by belt transmission, without the need for a steering gear, it is beneficial to improve the transmission efficiency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com