Bolt cleaning stirrer

A bolt cleaning and agitator technology, which is applied in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using liquids, etc., can solve the problems of difficulty in stirring and affecting the cleaning effect, so as to facilitate disassembly, assembly and replacement, and ensure cleaning efficiency. , Improve the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

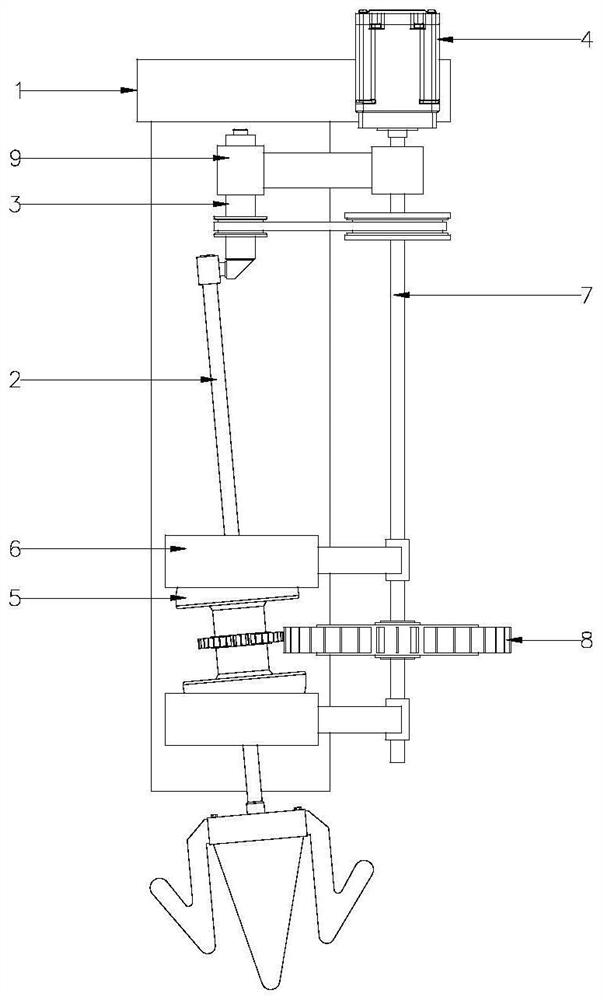

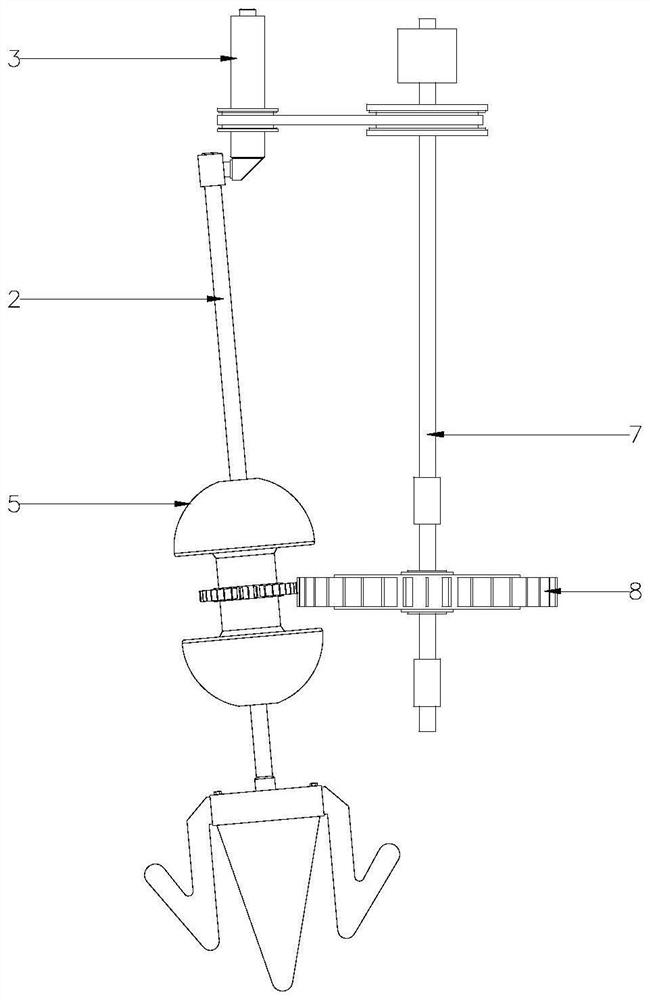

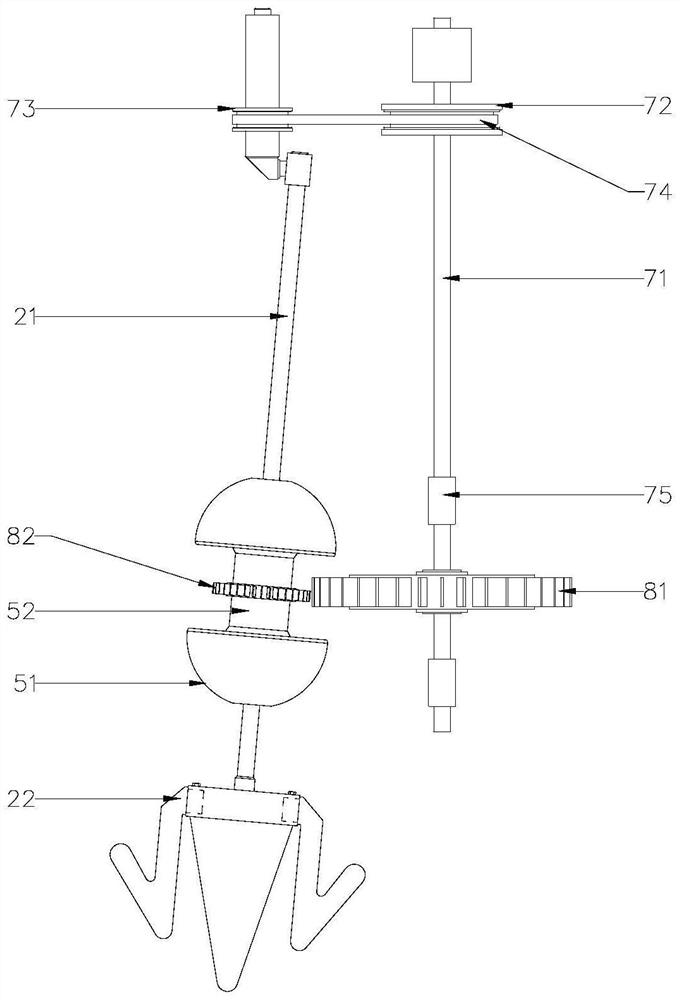

[0020] refer to Figure 1 to Figure 4 , a bolt cleaning agitator of the present invention includes a bracket 1, a stirring paddle 2, a rotating cylinder 3, a motor 4, a sphere 5, a ball seat 6, a revolution transmission assembly 7, a cylinder seat 9 and a controller, and the stirring paddle 2 includes Stirring rod 21 and stirring head 22, described stirring rod 21 is arranged obliquely and the top is fixed on the outer wall of rotating drum 3 and the bottom end is connected with stirring head 22, and described sphere 5 is installed outside stirring rod 21 and is rotatable Connected in the ball seat 6, the motor 4, the cylinder seat 9 and the ball seat 6 are respectively fixed on the outer wall of the bracket 1, and the motor 4 drives the drum 3 to rotate in the cylinder seat 9 through the revolution transmission assembly 7 so that The inclined stirring paddle 2 is driven to rotate around the axis of the drum 3 , and the controller is electrically connected with the motor 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com