Transformer drying equipment

A technology for drying equipment and transformers, used in transformer/inductor cooling, chemical instruments and methods, filtration and separation, etc., can solve problems such as high cost, affecting normal power consumption, and requiring power outage treatment, achieving low cost and improving power supply reliability. Sex, the effect of raising the level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

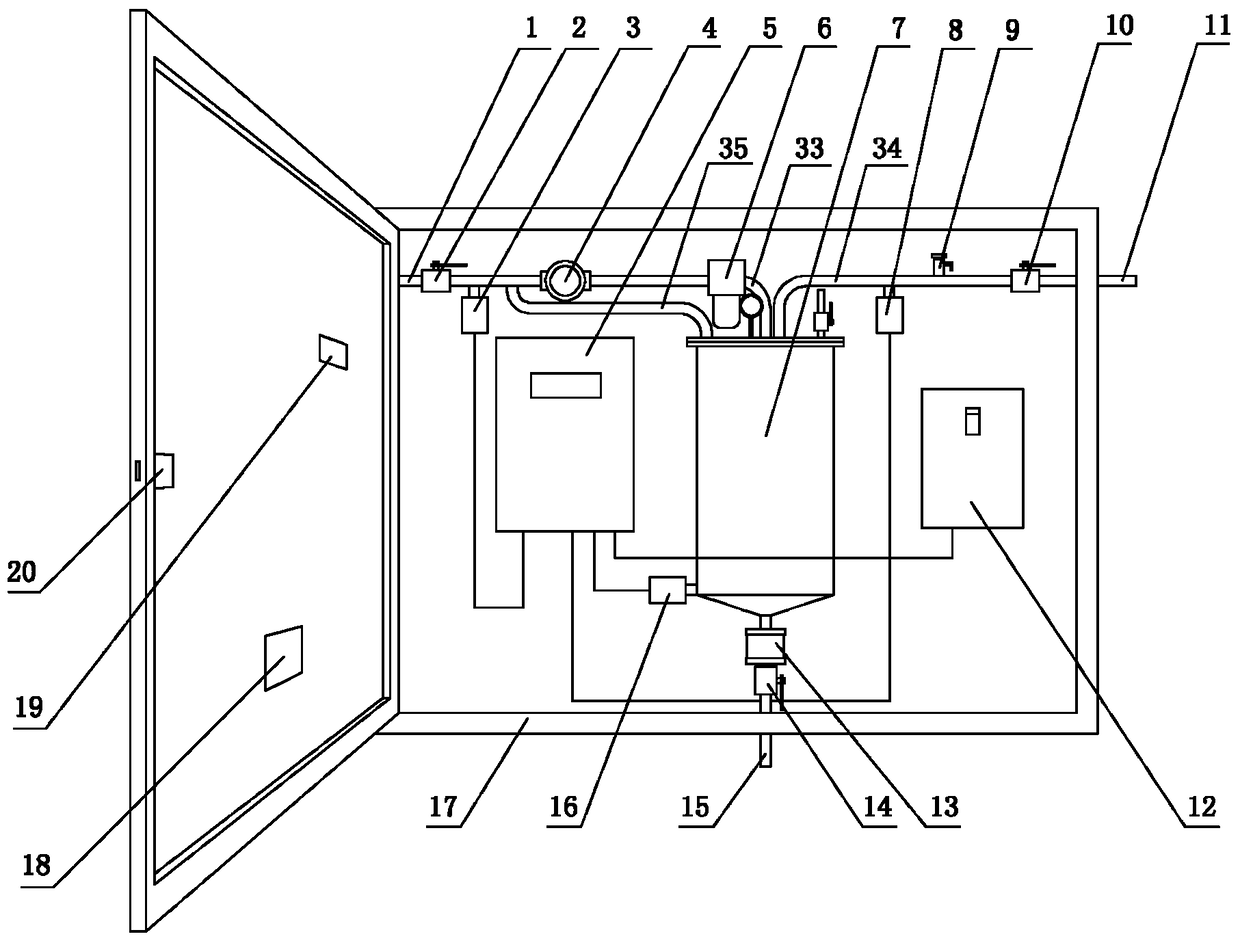

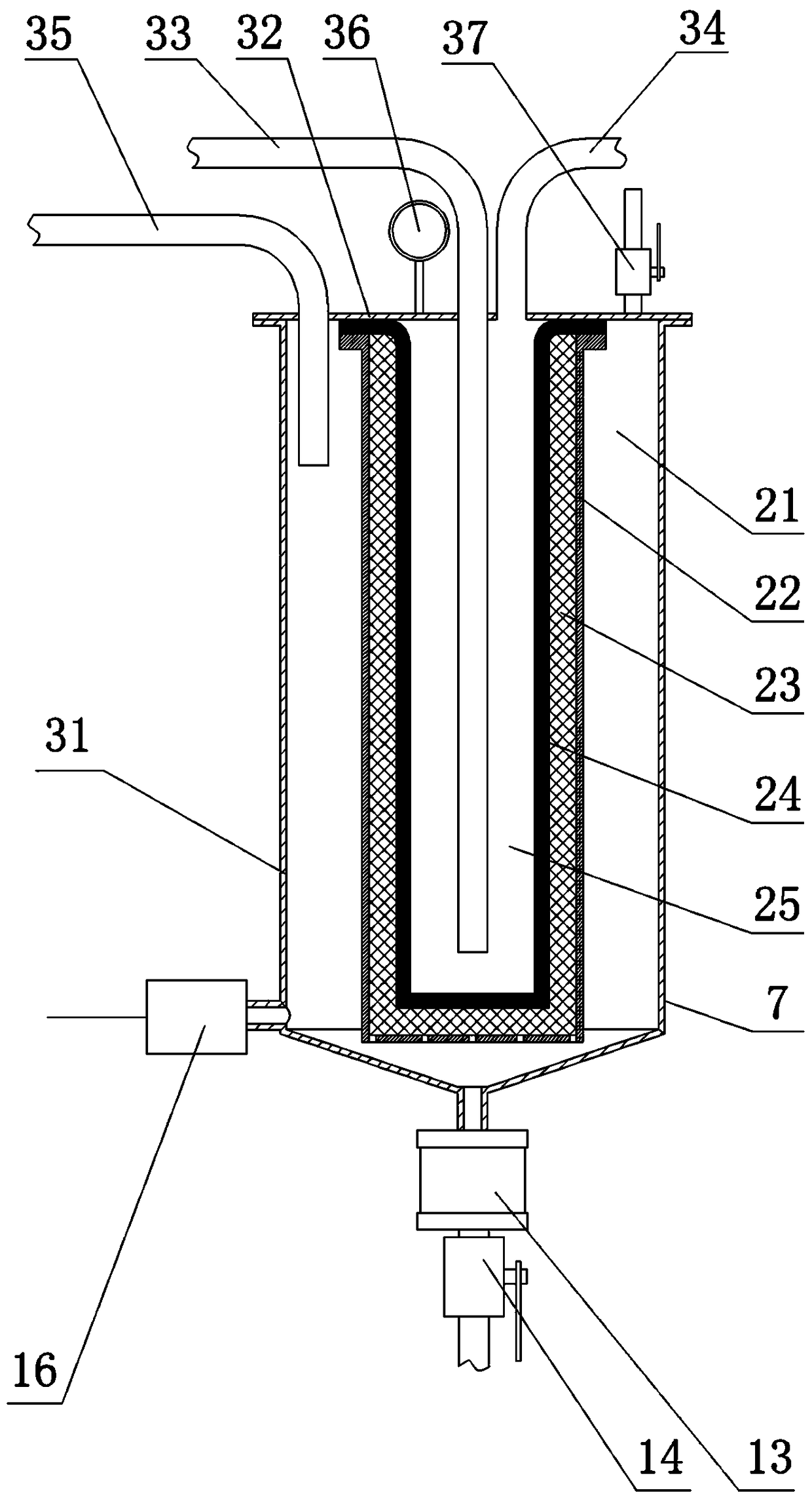

[0013] figure 1 Is a schematic diagram of an embodiment of a transformer drying equipment of the present invention, figure 2 Yes figure 1 Schematic diagram of the internal structure of the middle water removal tank 7; a transformer drying equipment, including the oil inlet pipe 1, the oil inlet valve 2, the oil inlet micro-water sensor 3, the oil pump 4, the micro-water measuring instrument 5, the oil filter 6, and the water removal tank 7. Oil discharge micro-water sensor 8, high-pressure tank discharge valve 9, oil discharge valve 10, oil discharge pipe 11, system control switch 12, water collector 13, water drain valve 14, water discharge pipe 15, water removal tank micro water sensor 16 , Box 17, water collector observation hole 18, micro-water measuring instrument observation hole 19, box door lock 20; one side of the oil inlet pipe 1 can be connected to the bottom of the transformer tank, and the other side of the oil inlet pipe 1 can be connected to the oil inlet valve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com