Flat filament drafting hot air chamber

A technology of hot air box and flat wire, which is applied in the field of packaging woven bags, can solve the problems of inconsistent heating rate, poor tensile resistance, different internal orientation of flat wire, etc., and achieve the effect of eliminating residual stress and strengthening mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

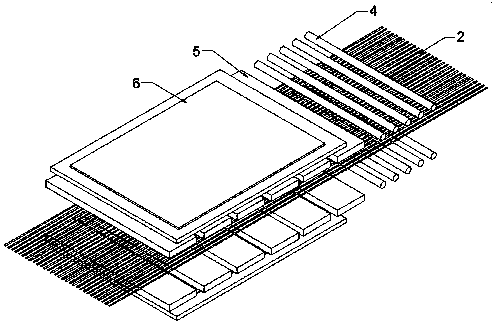

[0020] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0021] like Figure 1-3 As shown, a flat yarn drafting hot air box includes a box body 3, a cover body 1 is buckled on the top of the box body 3, and the cover body 1 and the edge of the box body 3 are connected and fixed by hinges. This design facilitates the opening and closing operations of the cover body 1 . In order to improve the sealing performance of the box body 3 and minimize the heat loss inside the box body 3 , an elastic sealing gasket is set on the fastening end faces of the cover body 1 and the box body 3 . The elastic sealing gasket is a polyurethane rubber sealing ring with good sealing performance.

[0022] In order to make the flat wire 2 smoothly enter the box 3 and then quickly output from the box 3, the side wall of the box 3 is provided with an inlet and an outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com