Textile roller safety protection taking and placing device

A safety protection and pick-and-place device technology, applied in the direction of internal accessories, etc., can solve the problems that the brush cannot be replaced separately, increase production costs, and easily damage the brush roller, so as to save handling time, improve work efficiency, and protect strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

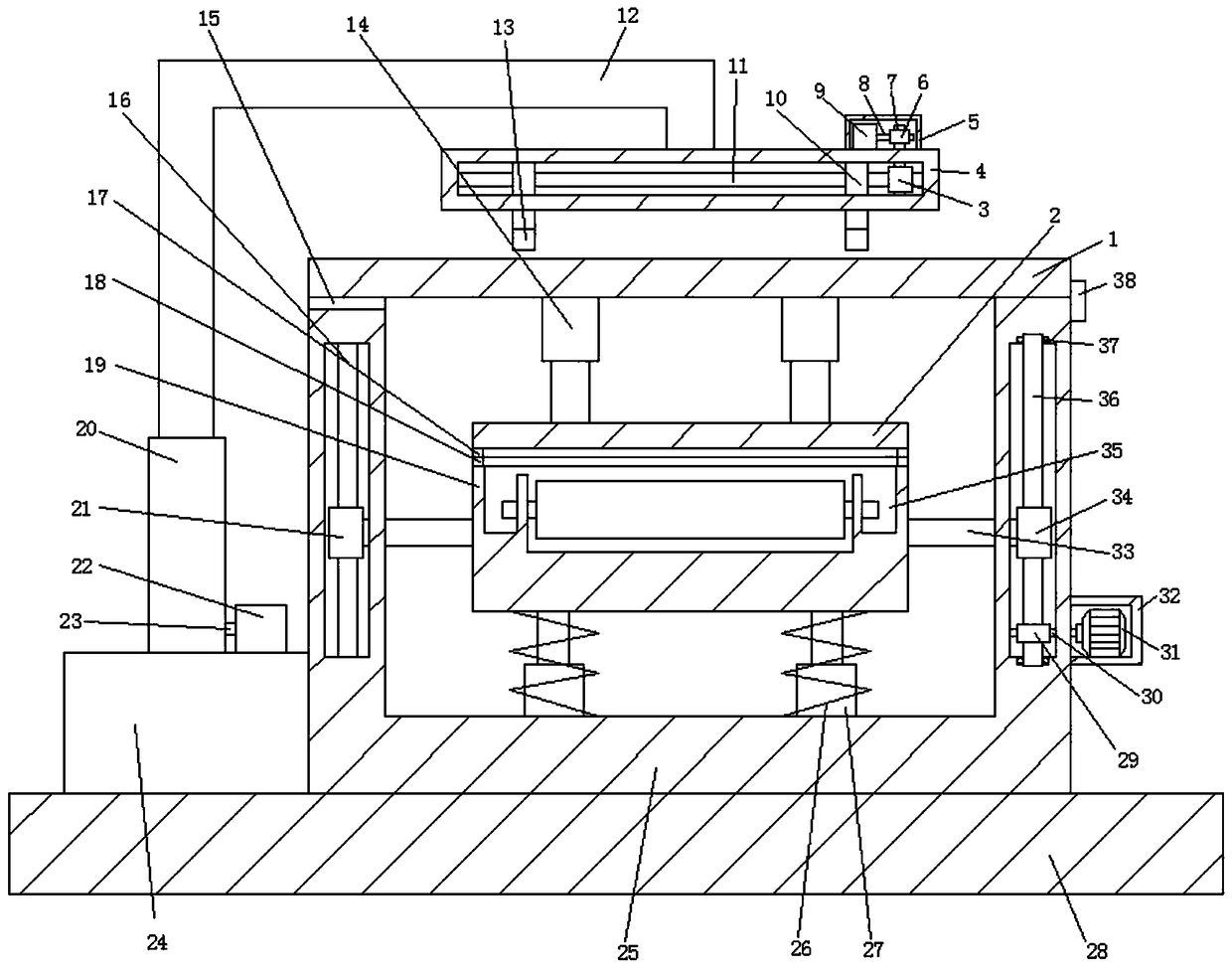

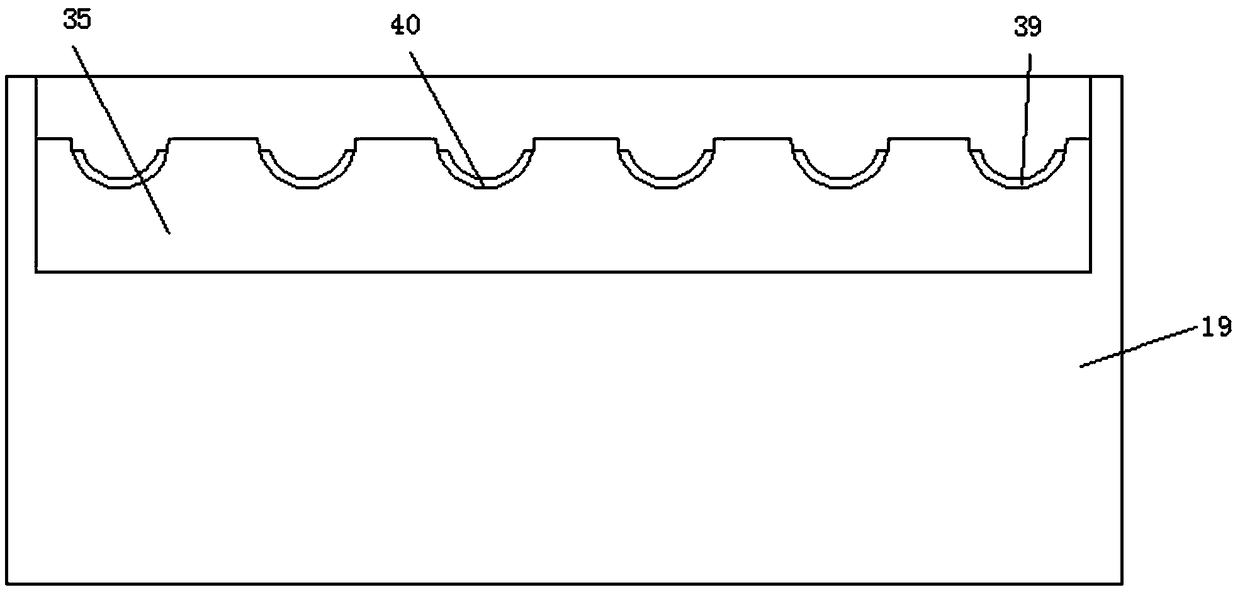

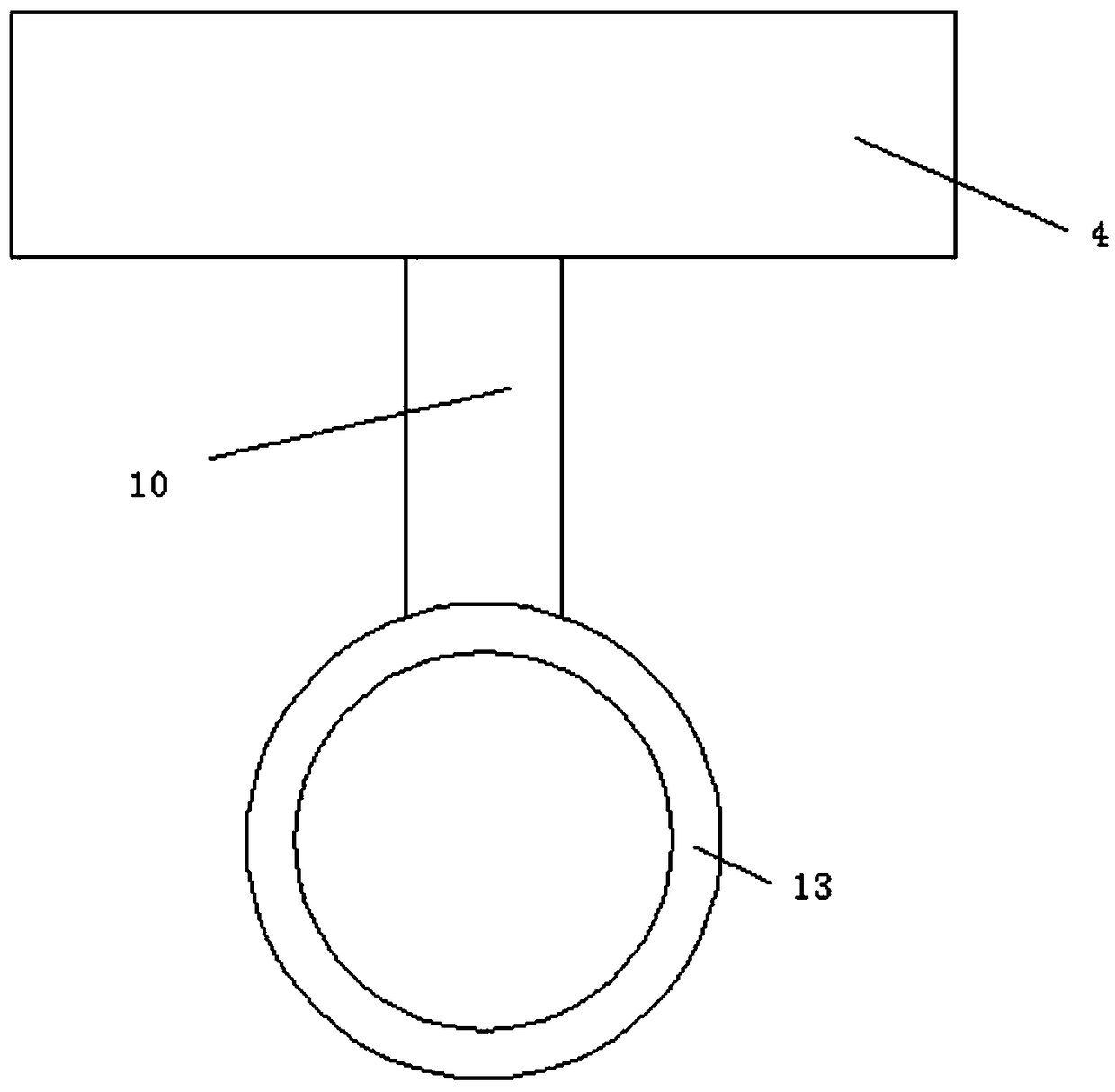

[0022] see Figure 1-4, a pick-and-place device for textile roller safety protection, including a base 28; the base 28 is made of steel, and is mainly used to provide an installation carrier for other parts of the device, and at the same time improve the overall stability of the device, and the upper surface of the middle part is fixedly welded with a main Frame body 25; the front view of the main frame body 25 is rectangular, which mainly plays the role of protective installation, and the outer surface of the lower left end is fixedly connected with a reinforcement block 24; the lower end of the reinforcement block 24 is fixedly installed on the upper surface of the left end of the base 28 , is mainly used for stabilizing and reinforcing, and the installation tube 20 is fixedly installed inside; the installation tube 20 is arranged on the left sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com