Valve rod and valve body assembling machine

A technology of assembly machine and valve body, which is applied in the field of machinery, can solve the problems that only manual tracking and elimination, the valve stem is not positioned, and the assembly cannot be completed, so as to reduce labor costs, equipment costs, and high assembly success rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

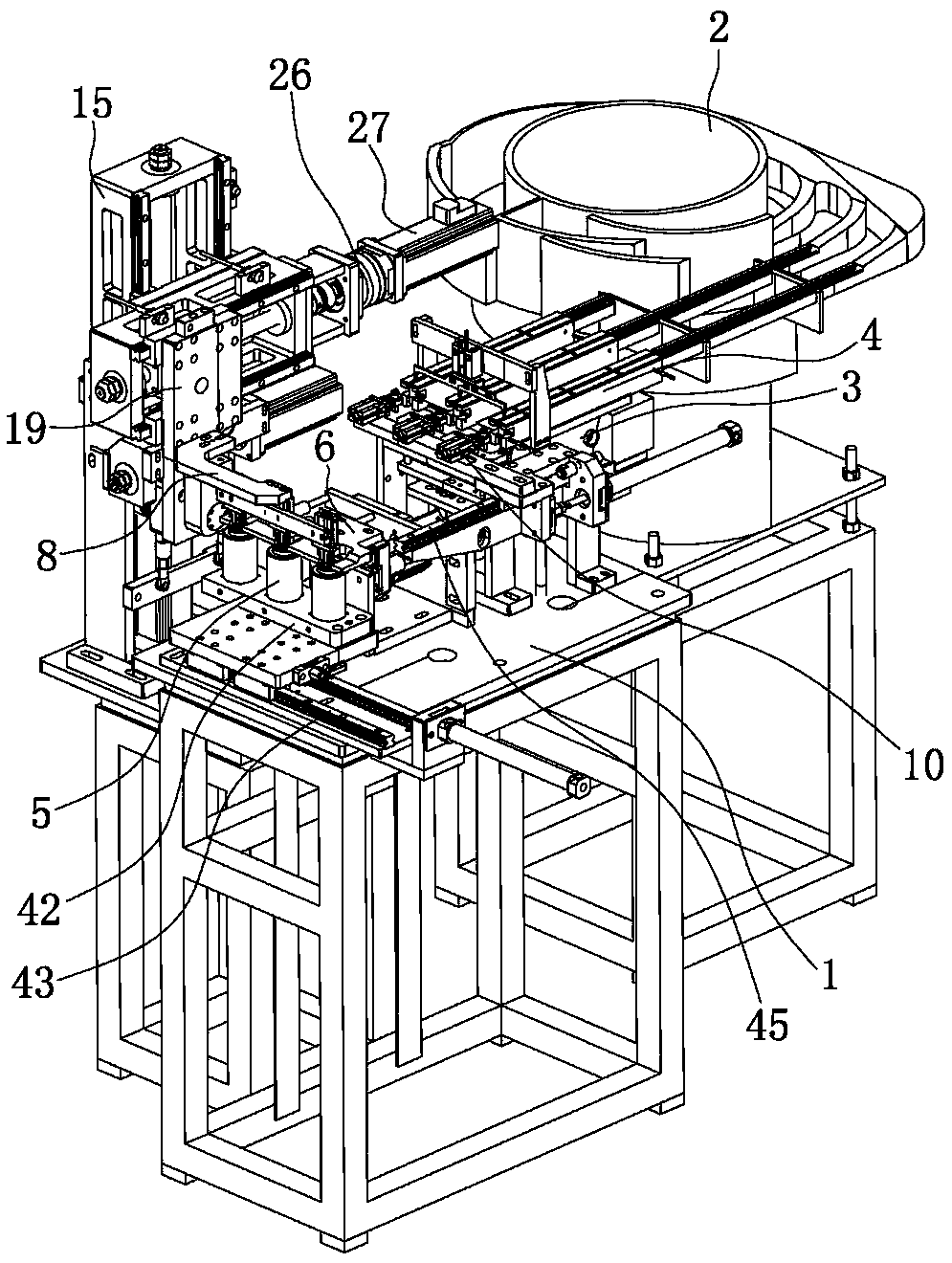

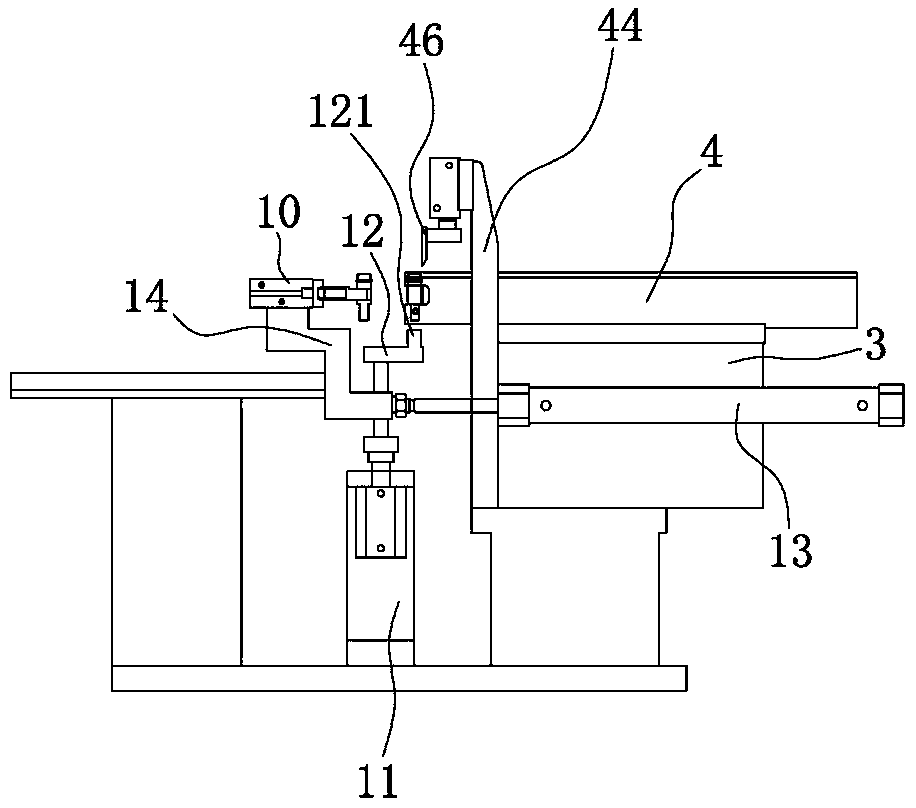

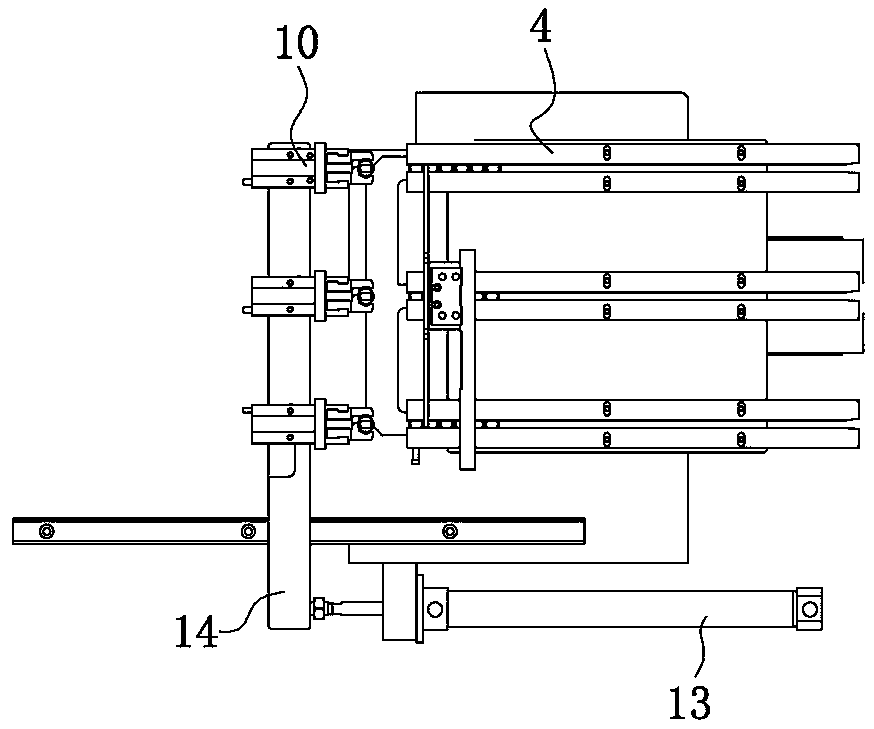

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 , Figure 9 and Figure 10 As shown, the valve stem and valve body assembly machine includes a workbench 1, which is provided with a vibrating plate 2 for conveying the valve stem, and a support frame 3 is fixedly connected to the workbench 1, and a vibration plate is fixedly connected to the support frame 3. The feeding slide rail 4 of the tray 2, the workbench 1 is set on the material retaining structure for separating the front valve stem and the inner valve stem in the conveying slide rail, and the workbench 1 is provided with a mold base 5, the mold base 5 has an installation cavity 51 for the valve body to be installed to achieve preliminary positioning. The workbench 1 is provided with a valve stem that transports the valve stem on the delivery slide rail to the mold seat 5 and installs the valve stem into the valve body in the mold seat 5. The valve stem in the hole is loaded into the device, ...

Embodiment 2

[0046] Such as Figure 11 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that when the installation cavity 51 of the mold base 5 is used for placing the valve body of the water distributor, the top of the mold base 5 is used for the water distributor. Each valve port of the valve body is exposed and the side gap 52 of the mold base 5 is exposed to each valve stem hole of the water distributor valve body. There are two ejector rods 31 located at both ends of the bottom of the mold base 5 respectively. There are two and corresponding to the ejector rods 31 one by one, the driving part is a cylinder, the cylinder is located at the center of the bottom of the mold base 5 and the piston of the cylinder is fixedly connected under the workbench 1, the cylinder body of the cylinder is fixedly connected to the bottom plate 33, and the two polished rods 34 are located at the two ends of the base plate 33 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com