Bonding fixture for small component

A component and clamping technology, applied in the direction of electrical components, electrical components, etc., can solve the problem of not being able to effectively fix small components, and achieve the effect of improving product quality and yield, improving yield, and improving bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment aims to provide a bonding fixture for small components, which overcomes the problem that small components cannot be effectively fixed during the bonding process, makes the bonding automatic production process stable and reliable, improves bonding accuracy, and improves product quality and good quality. Rate.

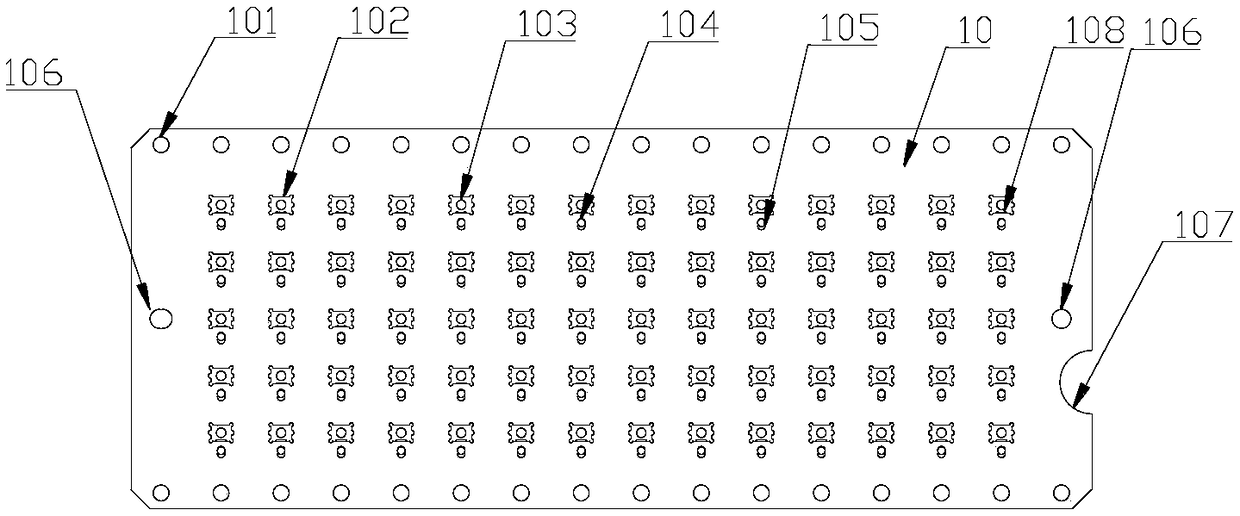

[0033] Such as figure 1 and figure 2 As shown, this embodiment provides a bonding fixture for small components, including a carrier 10 . The slide 10 is roughly square, with chamfered or rounded corners. In order to facilitate automatic production, a set of opposite sides of the slide 10 is provided with openings 101 (etching holes), which are convenient for automatic transmission to ensure stable and reliable transmission. Work slots 102 arranged in an array of 5 rows and 14 columns are arranged on the slide 10 .

[0034] Such as image 3 and Figure 4 As shown, the station groove 102 is roughly square, and its four corners are provided wit...

Embodiment 2

[0040] This embodiment aims to provide a bonding fixture for small components, which overcomes the problem that small components cannot be effectively fixed during the bonding process, makes the bonding automatic production process stable and reliable, improves bonding accuracy, and improves product quality and good quality. Rate.

[0041] This embodiment provides a bonding fixture for small components, including a carrier 10 . The slide 10 is roughly square, with chamfered or rounded corners. In order to facilitate automatic production, a set of opposite sides of the slide 10 is provided with openings 101 (etching holes), which are convenient for automatic transmission to ensure stable and reliable transmission. Work slots 102 arranged in an array of 5 rows and 14 columns are arranged on the slide 10 .

[0042] Station groove 102 is roughly square, and its four corners are provided with circular groove 109, and the depth of circular groove 109 is identical with the depth of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com