Friction disk for grounding device of high-speed train

A technology of grounding device and friction disc, which is applied to the installation of parts of connecting device, coupling device, connecting parts, etc., can solve problems such as bearing corrosion and bearing damage, reduce mechanical wear, reduce vibration amplitude and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

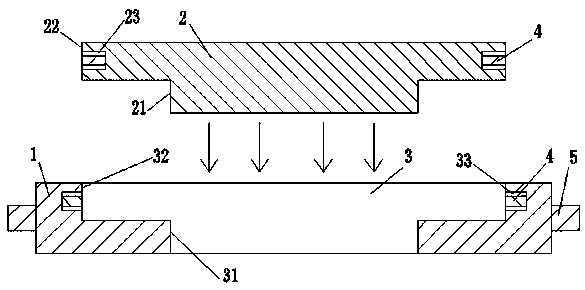

[0019] A friction disc for a high-speed rail grounding device, comprising a friction disc body 1, a friction body 2 is connected to the friction disc body 1, and a conductive wear-resistant coating is formed on the surface of the friction body 2;

[0020] The friction disc body 1 is provided with an inner cavity 3 for installing the friction body 2, the inner cavity 3 forms a stepped structure, wherein the lower part is provided with internal threads and is a small cavity 31, and the upper part forms a large cavity 32;

[0021] The side of the friction body 2 forms a stepped structure that cooperates with the inner cavity 3, the lower part of the side of the friction body 2 is provided with external threads and is a small shaft 21, and the upper part of the side forms a large shaft 22;

[0022] The small shaft 21 is mated with the small cavity 31 to form a connection, and the large shaft 22 is mated to the large cavity 32 to form a connection.

[0023] An inner cavity 33 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com