Photomask used for preparing liner-type BPS and liquid crystal display panel

A liquid crystal display panel and gasket technology, which is applied in the direction of originals for photomechanical processing, optics, and optomechanical equipment. It can solve the problems of large film thickness, small step difference, and affecting the range of liquid crystals, and achieve large step differences. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

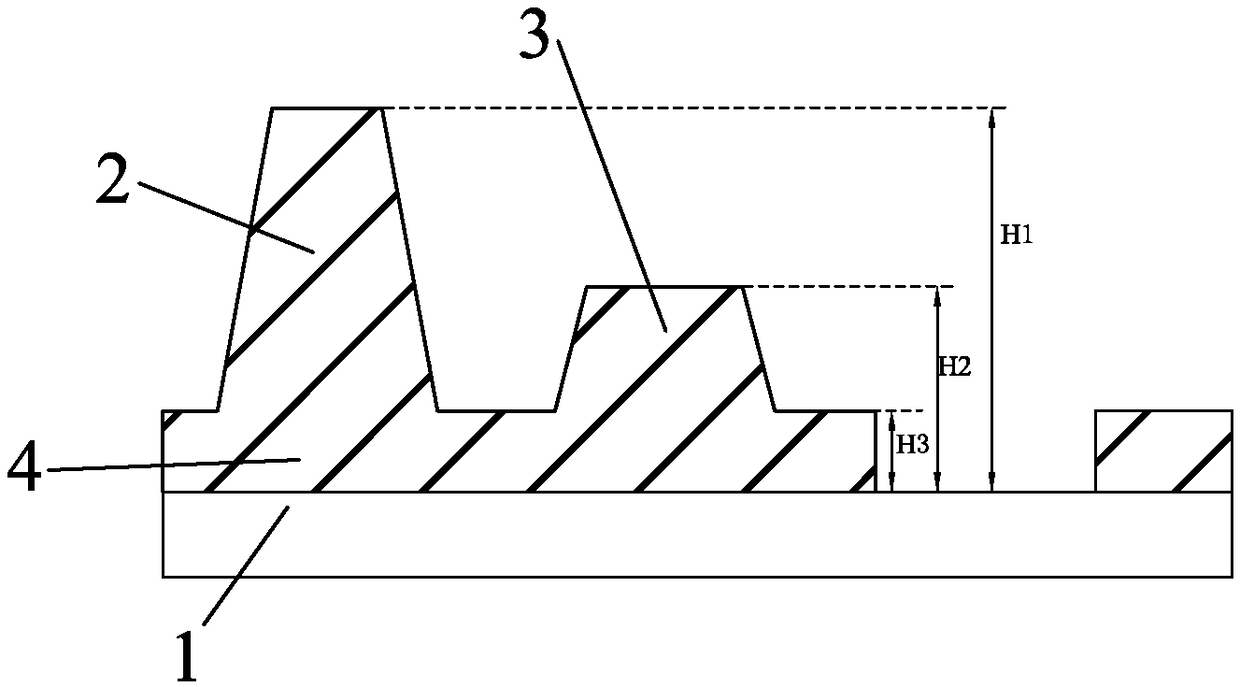

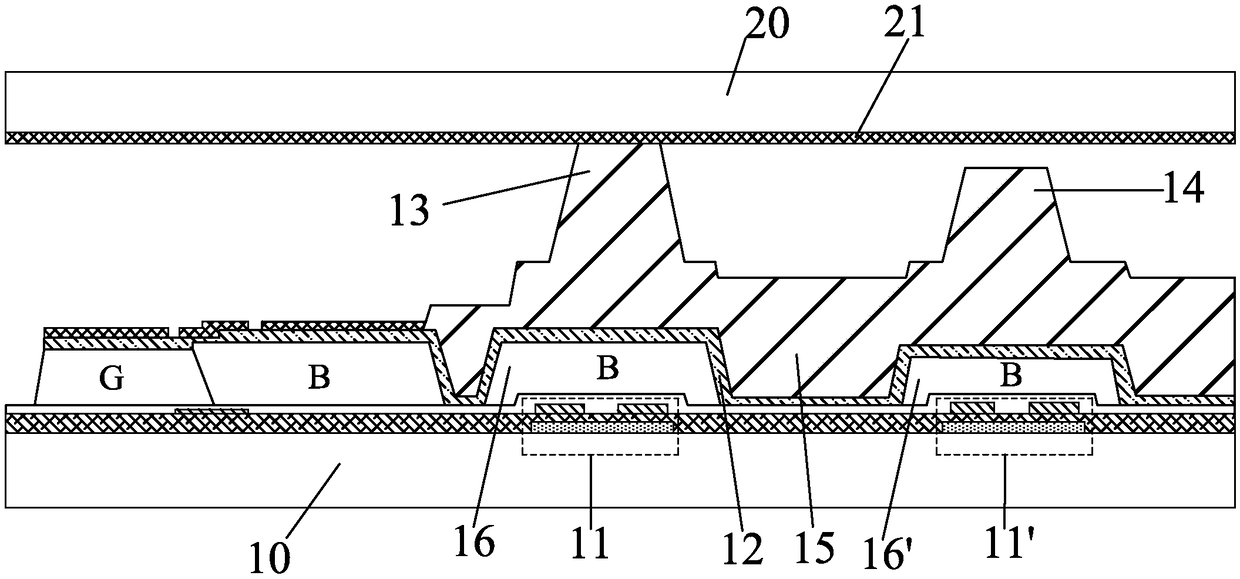

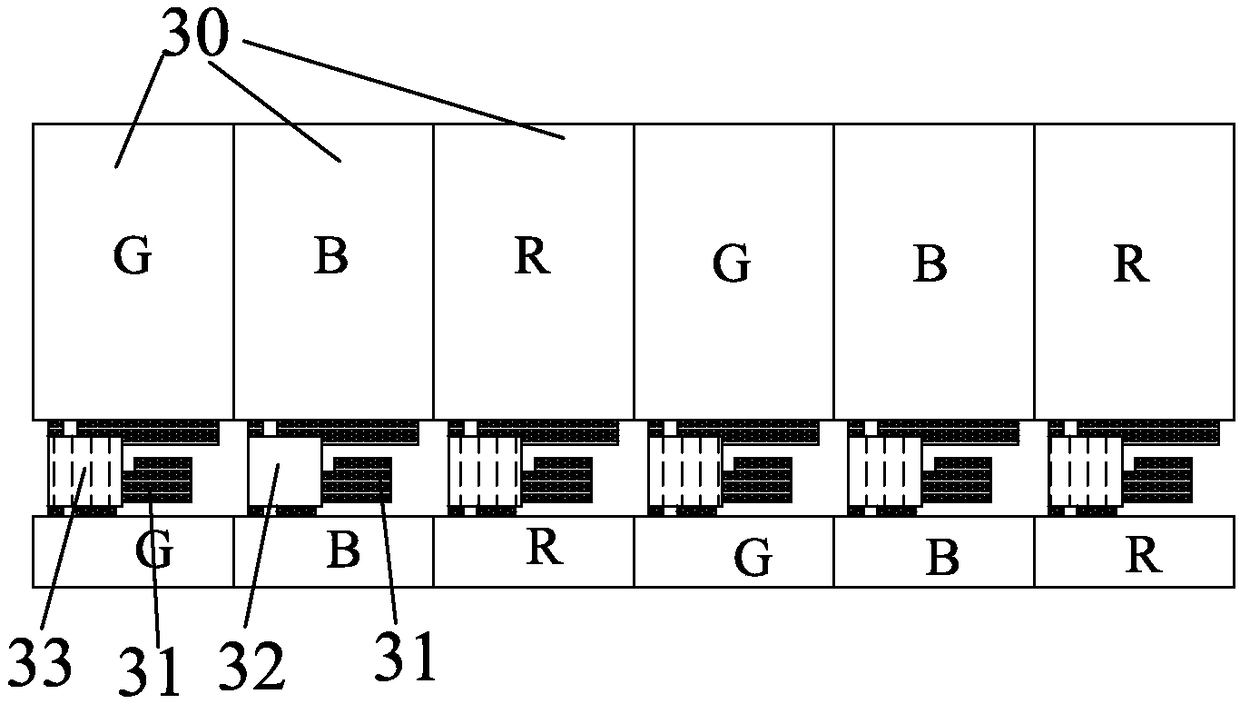

[0037] Figure 6AShown is a top view of a conventional photomask 40 for making a pad-type BPS, Figure 6B is a top view of the color-resist pattern corresponding to the application of the photomask 40, Figure 6C It is a cross-sectional view of the main spacer color resist liner 41 formed by using the photomask 40 . The photomask 40 is provided with a liner pattern 42 for forming the color-resist liner 41 of the main spacer, and the liner pattern 42 is a large-opening light-transmitting area; the photomask 40 further includes an RGB color-resist pattern 43 for forming an RGB color-resist 44. The RGB color resist pattern 43 is a light-transmitting area with a large opening. The existing RGB color-resist pattern 43 and spacer pattern 42 are designed to be light-transmitting as a whole, that is, the light transmittance T=100%, and the height of the color-resist liner 41 of the main spacer formed on the substrate 100 is H.

[0038] Figure 6D It is a top view of the mask 50 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com