Field rapid installation device for sensing optical cable, and installation method of device

A technology of sensing optical cable and installation device, which is applied in the direction of optical fiber/cable installation, etc., can solve the problems that the strain transmission performance of sensing optical cable is greatly affected, the scale and length are not completely covered, and it is difficult to quickly lay sensing optical cable. The effect of promoting the use of the area, optimizing the anchoring method, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

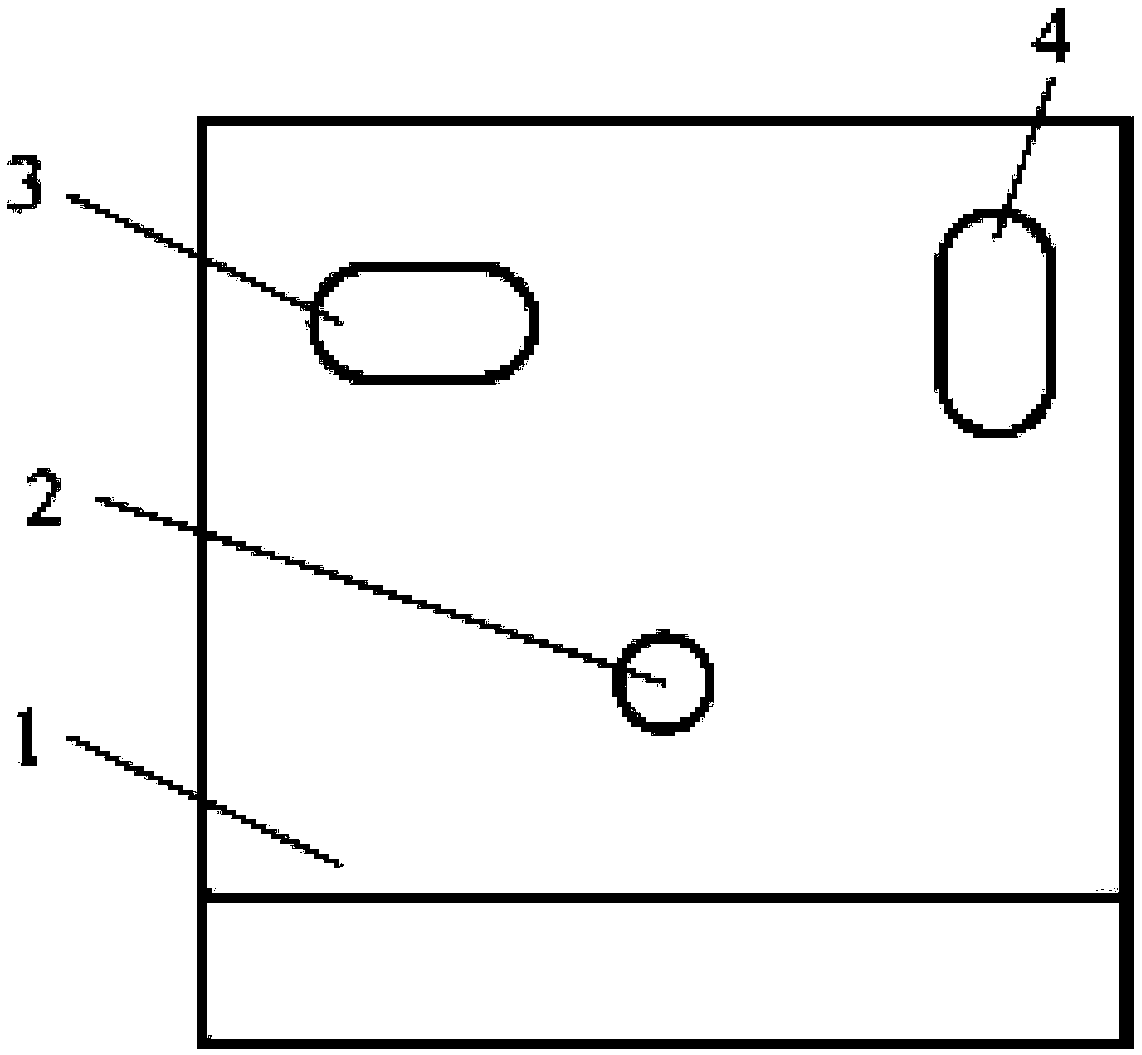

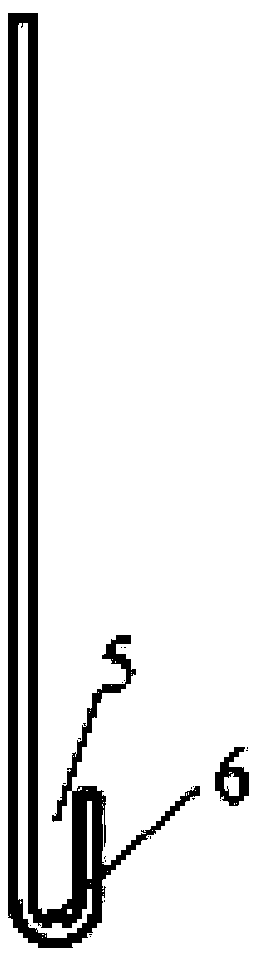

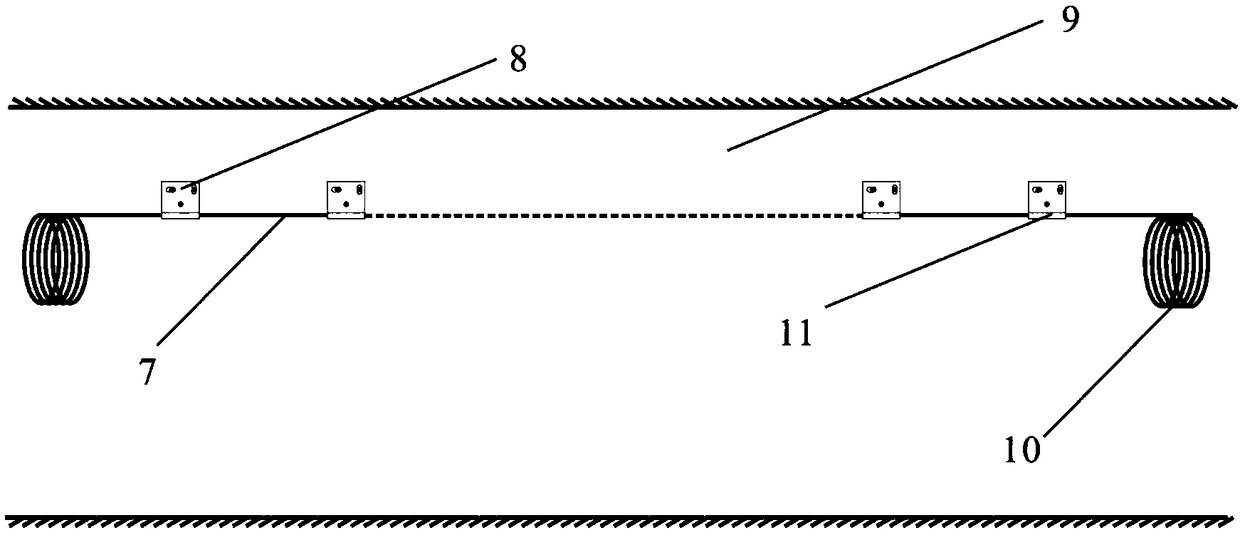

[0027] Such as figure 1 with figure 2 As shown, an on-site quick installation device for sensing optical cables includes a metal panel 1. The metal panel 1 is provided with positioning installation holes 2 and fine-tuning installation holes, respectively, and an optical cable card slot 5 and an optical cable card slot are provided under the metal panel 1. There are several metal bumps in 5 6. Further, the metal panel 1 adopts a high-strength thin-walled steel plate.

[0028] Further, the positioning and mounting hole 2 is provided at the center of the metal panel 1 to play a role of preliminarily fixing the device.

[0029] Further, the fine-tuning mounting holes include a horizontal fine-tuning mounting hole 3 and a longitudinal fine-tuning mounting hole 4. The horizontal fine-tuning mounting hole 3 and the longitudinal fine-tuning mounting hole 4 are respectively provided on the upper part of the metal panel to provide horizontal and vertical fine-tuning spaces respectively. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com