Coupling heat supply system used for highway service area and heat supply method of coupling heat supply system

A heating system, high-speed service technology, applied in heating systems, household heating, household heating and other directions, can solve problems such as large building heat load, unbalanced underground soil temperature, wind energy instability and intermittent, etc. The effect of good technical and economic effect and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

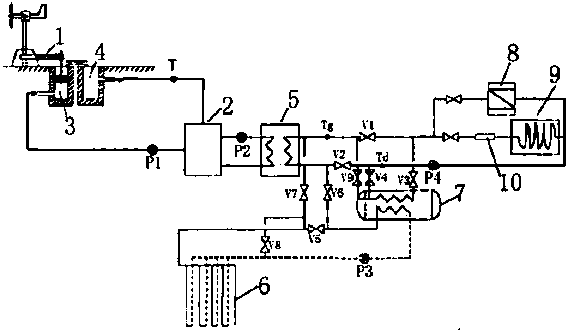

[0031] The coupled heat supply system provided by the present invention is composed of three parts: wind energy heat collection device, soil buried heat exchange device and heat collection device, wherein the wind energy heat collection device and soil buried heat exchange device pass through the air heat exchanger 5 and the plate heat exchanger respectively. Heater 7 realizes heat exchange with heat collecting device.

[0032] The above-mentioned wind energy heat collection device includes a wind turbine unit 1, an air circulation pipeline, an air storage device 2 and a wind energy heat exchange pipeline. During the working process, the air enters the brake 3 of the wind turbine unit 1 through the air pump P1, and is quickly transferred to the wind turbine unit 1 after being heated by the unit. The hot air tank 4 is kept warm, and then flows back to the air storage device 2 through the pipeline, and the heated circulating air flowing back to the air storage device 2 enters the...

Embodiment 2

[0045] In this embodiment, except that the circulating medium of the wind energy heat collection device is replaced with water, other settings are the same as in embodiment 1. Meanwhile, the medium storage device of the wind energy heat collection device is replaced with a heat preservation and moisturizing water tank, and the pump is replaced accordingly.

Embodiment 3

[0047] In this embodiment, except that the circulating medium of the wind energy heat collecting device is replaced with a mixture of water and ethylene glycol, other settings are the same as in embodiment 1, wherein the volume ratio of water to ethylene glycol is 4:1, and the medium of the wind energy heat collecting device The storage was replaced with an insulated hydration tank and the pump was replaced accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com