Colored active organic functional cereal fiber, and preparation method and application thereof

A functional fiber and colored technology, applied in the fiber field, can solve problems such as dark color, decreased aesthetics, poor color fastness, etc., achieve bright color, improved color fastness, and satisfy the effect of repeated wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] According to one aspect of the present invention, the present invention provides a kind of preparation method of colored active organic functional fiber of five grains, comprising the following steps:

[0034] (a) uniformly mixing the vegetable protein solution, the polyvinyl alcohol solution and the color paste to obtain a spinning stock solution;

[0035] (b) Spinning the spinning dope to obtain nascent fibers;

[0036] (c) performing wet-heat drafting and dry-heat drafting sequentially on the as-spun fibers to obtain drawn fibers;

[0037] (d) subjecting the stretched fiber to cross-linking and color-fixing treatment to obtain five-grain colored active organic functional fiber.

[0038] In the present invention, vegetable protein includes isolated protein extracted from soybeans, peanuts, cottonseed or rapeseed by soaking, wet grinding, or directly from soybeans, peanuts, cottonseed or rapeseed through crushing, degreasing, soaking or Protein isolates extracted fro...

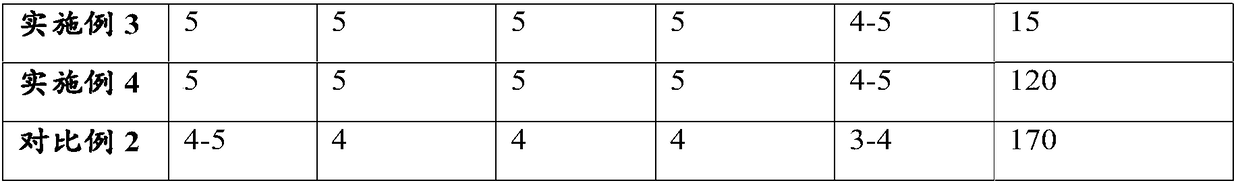

Embodiment 1

[0094] The present embodiment provides a kind of preparation method of blue soybean protein fiber, comprises the steps:

[0095] (1) Soybean protein and water are added in the dissolving machine, then in the dissolving machine, adding a concentration of 10% sodium hydroxide solution, the dissolving machine is stirred at a speed of 45r / min, and the dissolving machine is heated up to 85 ℃, stirred for 6 hours to obtain a soybean protein solution with a concentration of 6-10%, and then kept the soybean protein solution for 8 hours;

[0096] (2) Polyvinyl alcohol is dissolved in water to obtain a polyvinyl alcohol solution;

[0097] (3) mix polyvinyl alcohol solution and soybean protein solution in dissolving machine, and make the mass ratio of polyvinyl alcohol and soybean protein be 70:30, then add concentration and be 10% sodium hydroxide solution and mix uniformly, dissolving machine Stir at 100°C for 4 hours at a speed of 60r / min to obtain a mixed solution of polyvinyl alcoh...

Embodiment 2

[0113] This example provides a blue soybean protein fiber. The difference between this example and Example 1 is that formaldehyde is used instead of glutaraldehyde in the cross-linking color-fixing treatment agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com