Hydrocyclone desanding device and utilization method thereof

A hydrocyclone and water flow technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as short water inlet channel, wear of pump body, easy deposition of sand particles, etc., to achieve Reasonable structural design, low floor space and high sand removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

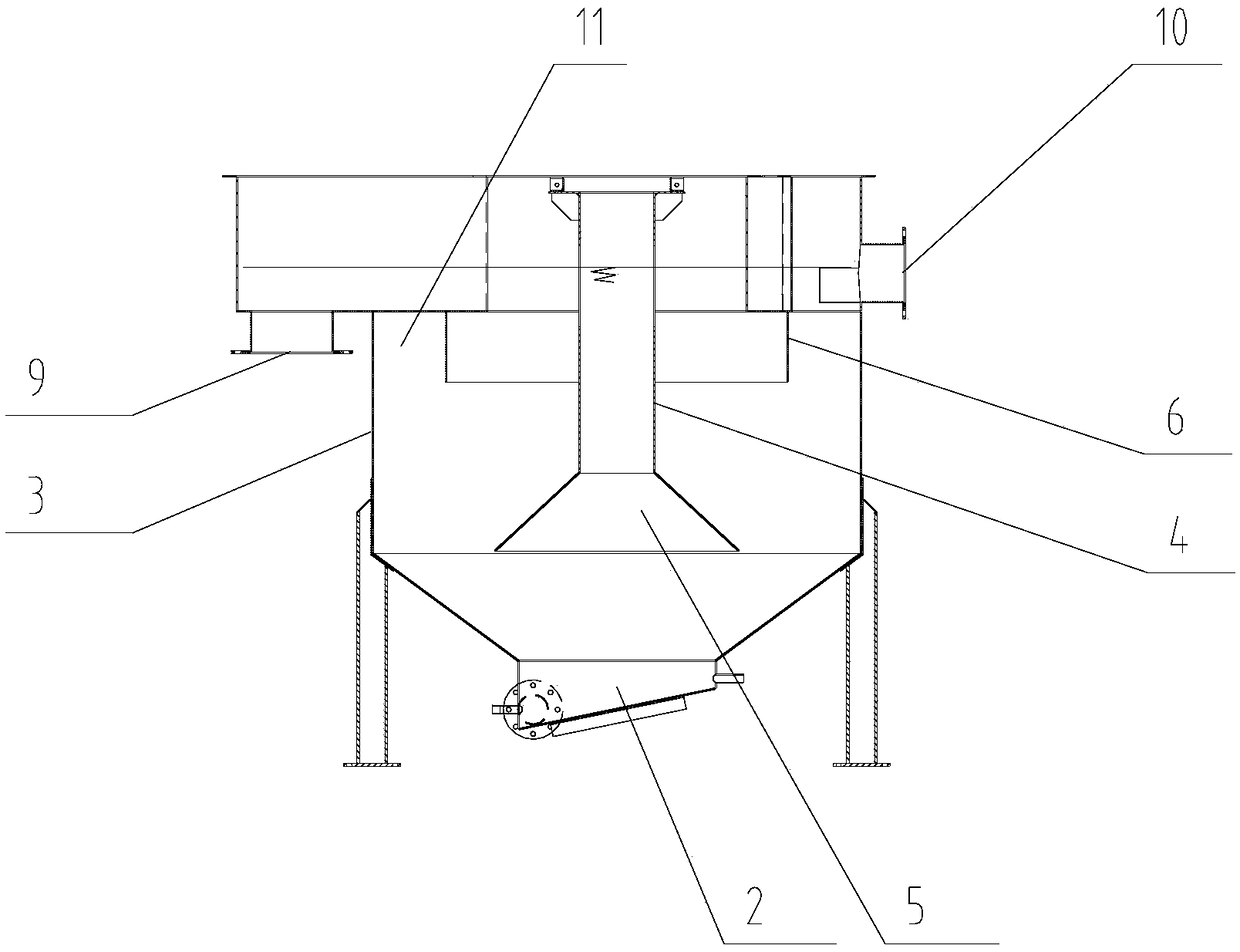

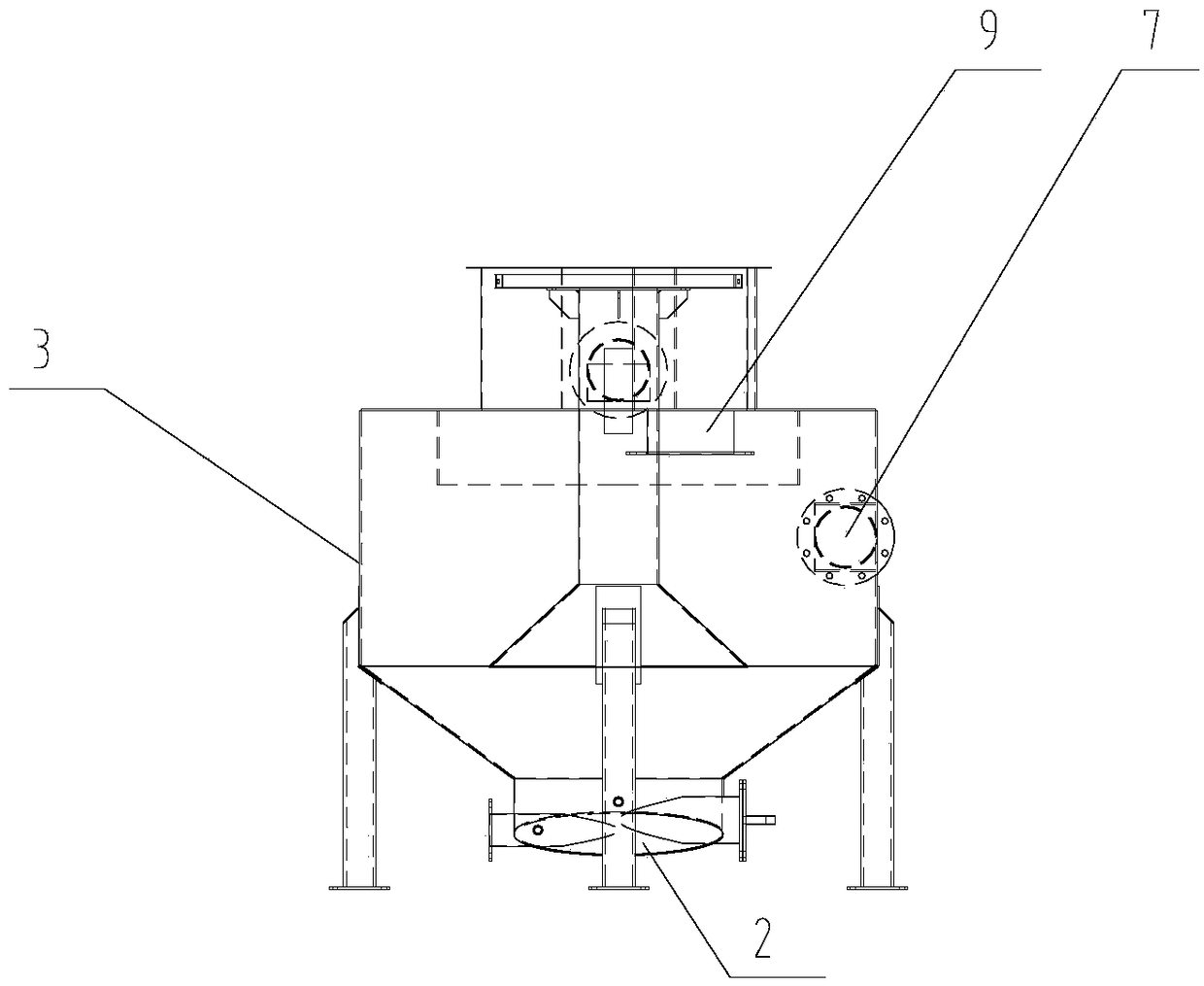

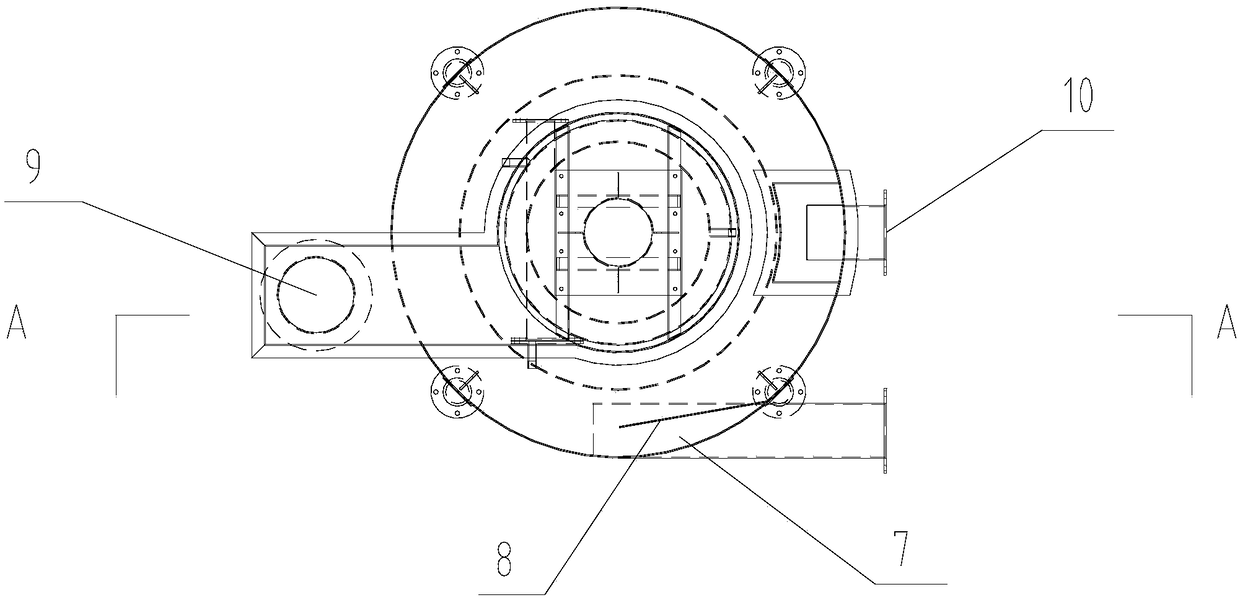

[0031] Attached below Figure 1-4 The hydrocyclone desanding device of the present invention and its usage method are described in detail.

[0032]A hydrocyclone desanding device, the device includes a sand distribution part 1 and a sand bucket part 2; the sand bucket part is arranged below the sand distribution part; the sand bucket part and the sand distribution part are transitionally connected through an annular slope; The sand dividing part includes a cylindrical cavity 3, a central shaft tube 4 that is concentric with the cylindrical cavity and arranged in the cylindrical cavity, and a central cone tube 5 is connected to the bottom of the central shaft tube; it is arranged in the middle and upper part of the cylindrical cavity And concentric with the cylindrical cavity, and the suspension sleeve 6 between the central shaft cylinder and the outer wall of the cylindrical cavity; The bottom plate of the water area is connected, and extends downward into the water in the cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com