MOTOR CONTROL DEVICE, PRINTER and control method

A technology of motor control and control method, applied in the direction of motor generator control, printing device, control system, etc., can solve problems such as imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

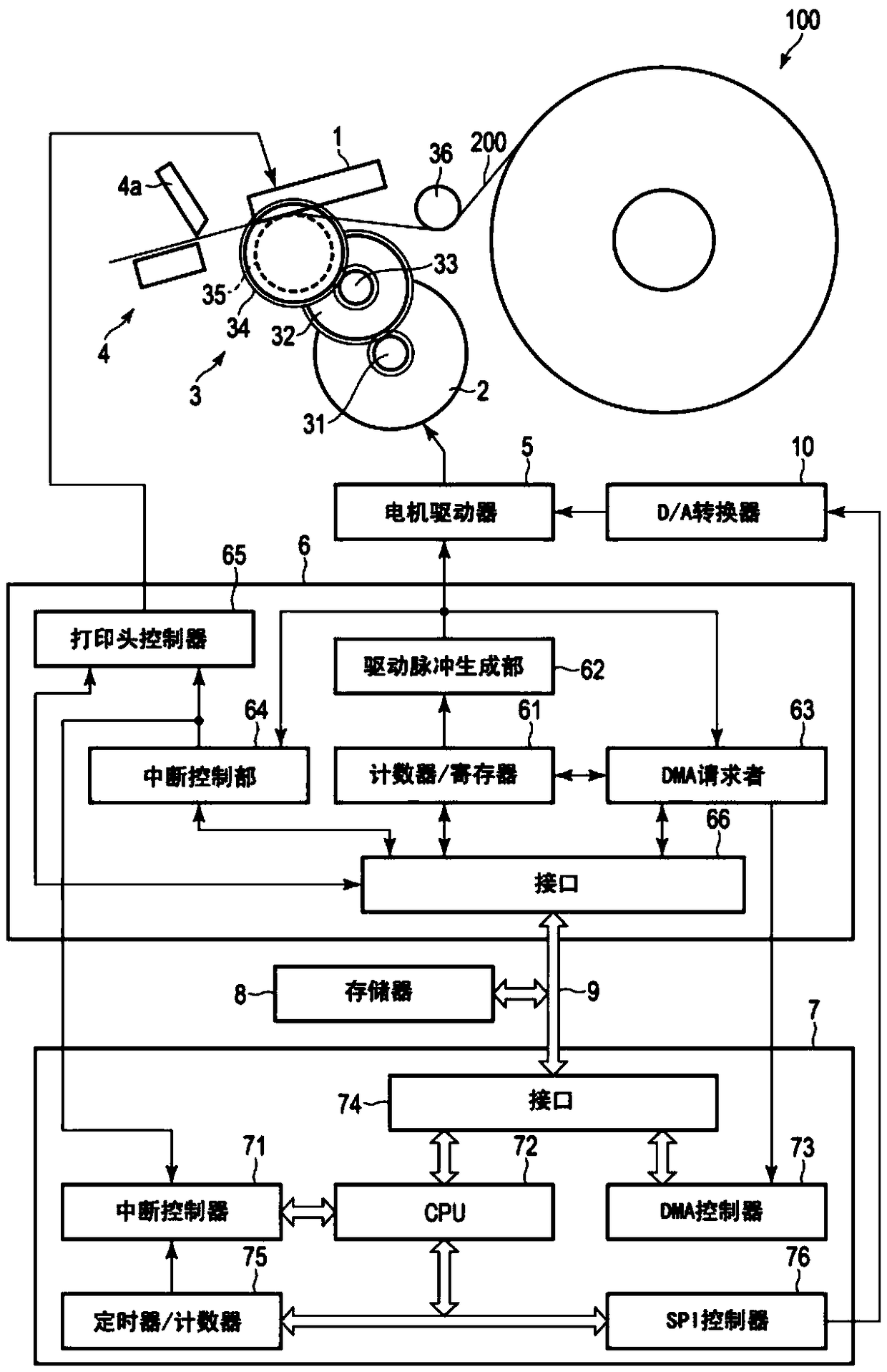

[0048] Hereinafter, an embodiment will be described with reference to the drawings. figure 1 It is a diagram showing the configuration of a part of the mechanism and the block configuration of main circuits of the printer according to the present embodiment. In addition, in this embodiment, a thermal printer is taken as an example for description. Such as figure 1 As shown, the printer 100 includes a thermal print head 1, a stepping motor 2, a conveying mechanism 3, a cutting unit 4, a motor driver 5, a drive control part 6, a printer control part 7, a memory 8, a bus 9 and a D / A (Digital / Analog: digital / analog) converter 10.

[0049] The thermal print head 1 is a type of print head, and prints an arbitrary image on the print medium 200 by discoloring the print medium 200 through heat generated by each of a plurality of heating elements. The thermal print head 1 can change the heating temperature of each of the plurality of heating elements individually and in multiple stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com