Sanitary coffin reinforcing plate processing device

A processing device and reinforcement plate technology, applied in metal processing, mechanical processing/deformation, etc., can solve the problems of low forming efficiency, unreasonable structural design, single choice of plate shape and thickness, etc., and achieve stable quality and design structure Simple and efficient molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

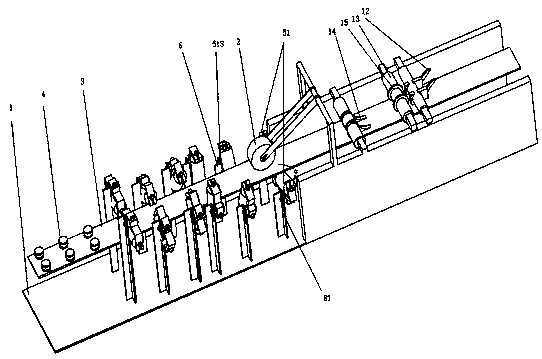

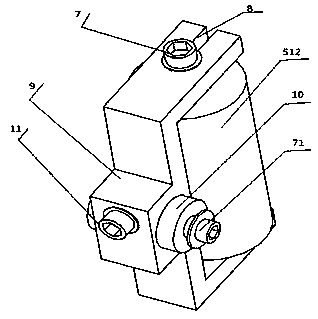

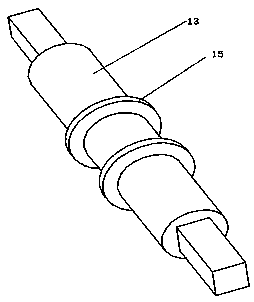

[0022] refer to Figure 1~3 , a sanitary coffin reinforced plate processing device in the present embodiment includes a frame 1, a material carrier plate 3, a slotting device, a pressing roller 2, a bending device, and a shaping mechanism 4; the material carrier plate 3 is arranged on the frame 1 is used to carry the reinforcement plate 16 for transmission. The bending device includes 6 pairs of guide rollers, which are arranged in sequence along the transmission direction of the reinforcement plate. A pair of guide rollers 51, each pair of guide rollers includes two guide rollers, the two guide rollers are symmetrically and adjustable on both sides of the frame, the guide rollers 513 include guide rollers 512 and a fixed base 9, The central axis of the guide roller 512 forms an angle α with the horizontal plane of the material carrier plate 3 and the included angle gradually decreases along the conveying direction of the reinforcing plate; the pressure roller 2 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com