Clamp facilitating PDMS (Polydimethylsiloxane) die releasing and method for preparing PDMS layer thereby

A fixture and demoulding technology, applied in applications, flat products, household appliances, etc., can solve the problems of taking out the PDMS layer, demoulding is easy to break, and the molding effect is not good, so as to achieve enhanced light transmittance, good molding effect, Not easily broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

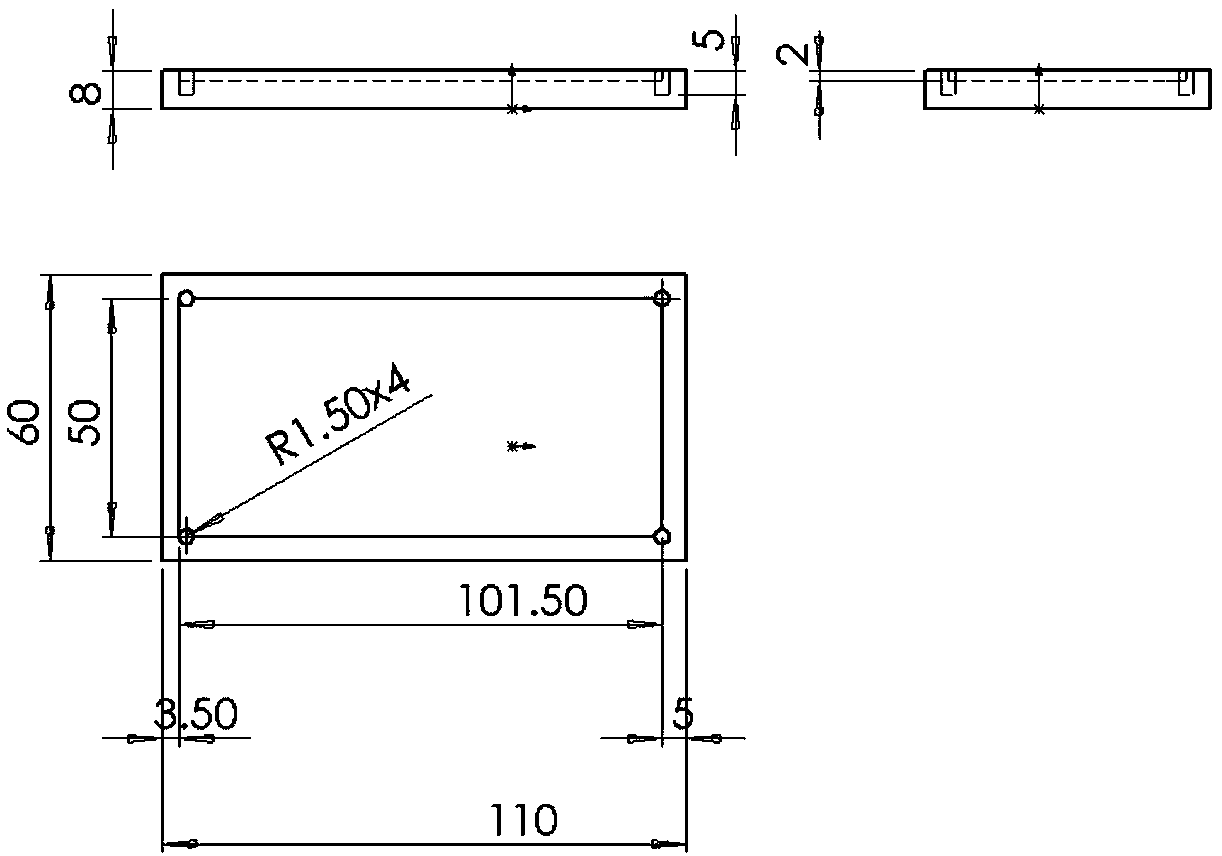

[0032] like Figure 1-6 As shown, the present embodiment provides a fixture that facilitates demoulding of PDMS, the fixture includes a base plate, an intermediate plate and a permanent magnet; the base plate is made of paramagnetic metal; the upper surface of the base plate is provided with a concave Groove, the depth of the groove is greater than the thickness of the middle plate; the groove also extends into the inner wall of the bottom plate with a plurality of demoulding holes evenly arranged along the periphery of the groove, and each of the demoulding holes communicates with the inside of the groove , and each of the demoulding holes runs through the upper surface of the bottom plate and extends to the bottom of the bottom plate; the bottom surface of the groove and can be taken out from the groove; the middle plate is made of ferromagnetic material; the permanent magnet is placed on the back of the bottom plate to attract the middle plate to close the surface of the mi...

Embodiment 2

[0039]This embodiment further limits the middle plate on the basis of embodiment 1 or 2. In this embodiment, the middle plate is provided with a plurality of rectangular holes; the plurality of rectangular holes are regularly arranged in a grid. The rectangular holes are used to make the surface of the cured PDMS layer have a cuboid spacer structure. This solution enables the mold to make the PDMS layer one-time pour molding, without reshaping the structure of the rectangular parallelepiped spacer array on the obtained PDMS layer.

Embodiment 3

[0041] This embodiment further limits the bottom plate on the basis of embodiment 1 or 2. The middle plate in this embodiment is placed in the middle of the groove of the bottom plate, and the distance between the middle plate and the inner wall of the groove is 0.5mm. The margin is used to remove and place the middle plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com