Iron casting grinding device

A cast iron and grinding table technology, applied in grinding/polishing safety devices, grinding machines, grinding workpiece supports, etc., can solve problems such as low efficiency and affect the progress of production, and achieve the effect of reducing workload and increasing grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings.

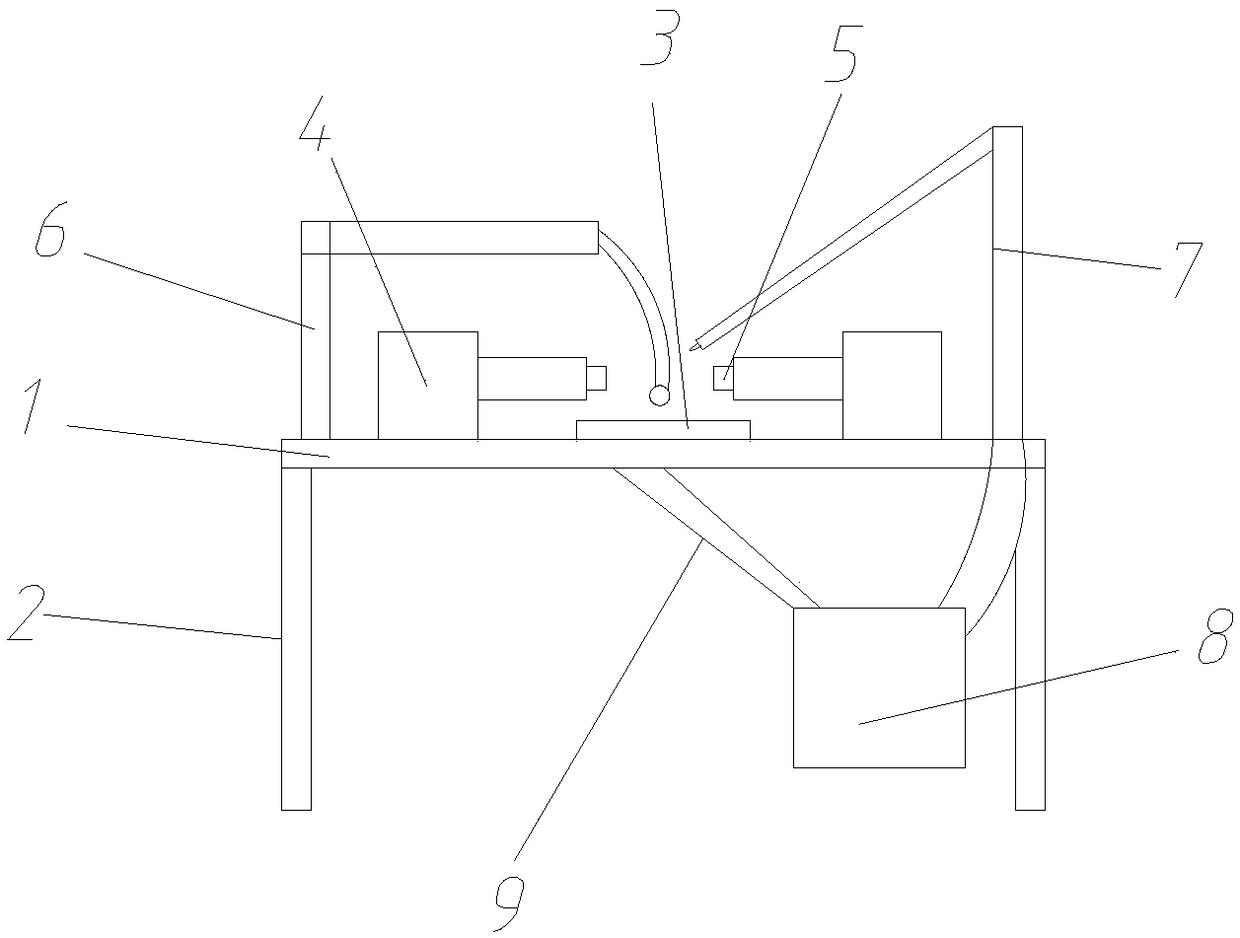

[0011] like figure 1 As shown, a cast iron grinding device includes a base plate 1, a grinding table 3, a clamping cylinder 4, a ball-milling manipulator 6 and a cooling water pipe 7, the base plate 1 is horizontal, and two supporting columns 2 are fixed vertically on both sides of the bottom. , the grinding table 3 is set at the center position of the bottom plate 1, the clamping cylinders 4 are two in total, and are arranged symmetrically on both sides of the grinding table 3, and the two telescopic rods are respectively stretched toward the center position, at the top of the telescopic rod A clamping block 5 is fixed; the ball mill manipulator 6 is installed on one side of the base plate 1, and the cooling water pipe 7 is installed at the other end of the base plate 1, and the two are respectively on both sides of the grinding table 3, and the cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com