Spacing adjusting working frame for welding steel structure profiles

A technology for working frames and steel structures, applied in welding equipment, auxiliary welding equipment, metal material coating technology, etc., can solve the problems affecting the quality of welding, the difficulty of aligning and matching two sections of profiles, etc., to ensure quality and facilitate welding Operation, convenient docking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

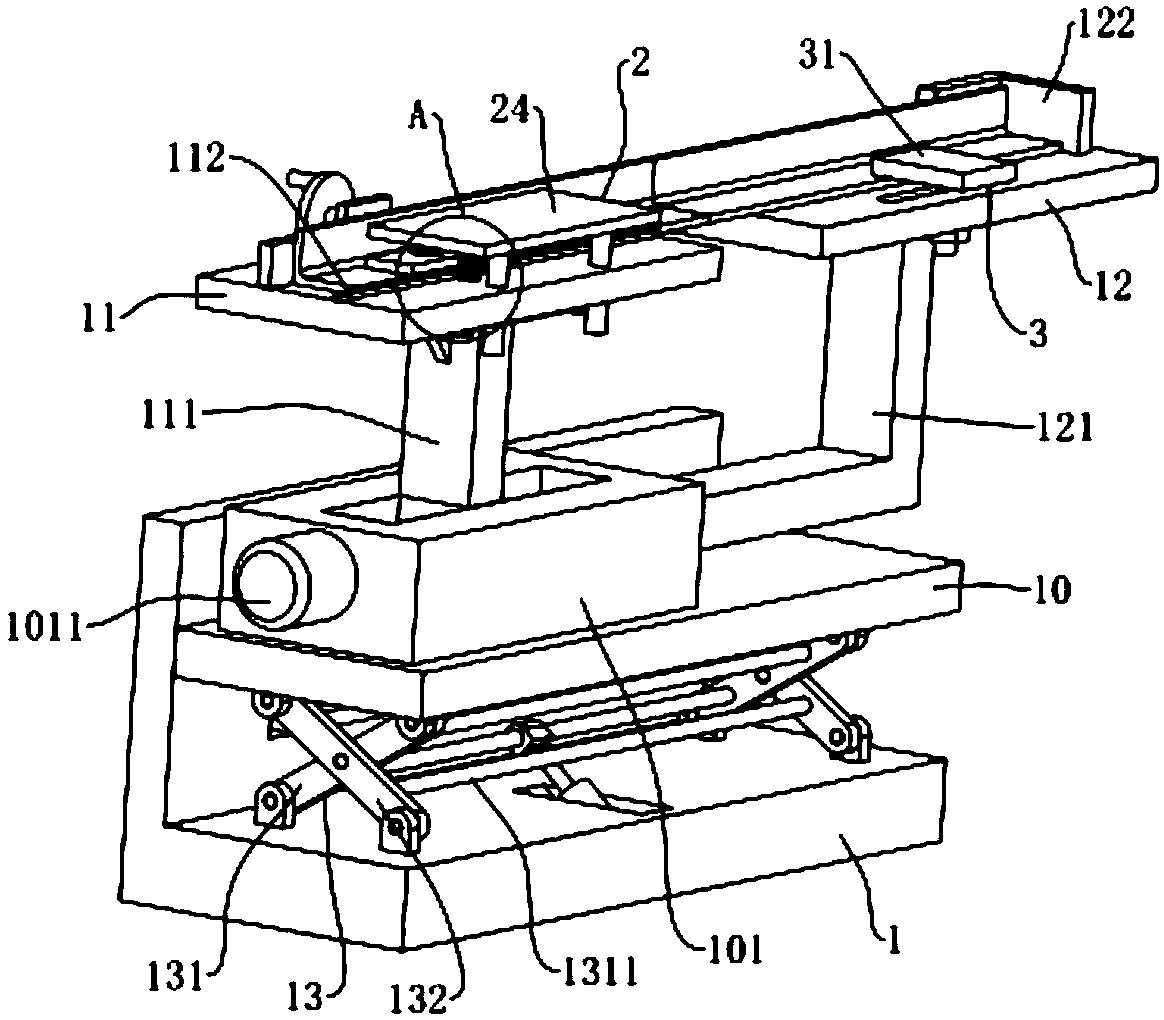

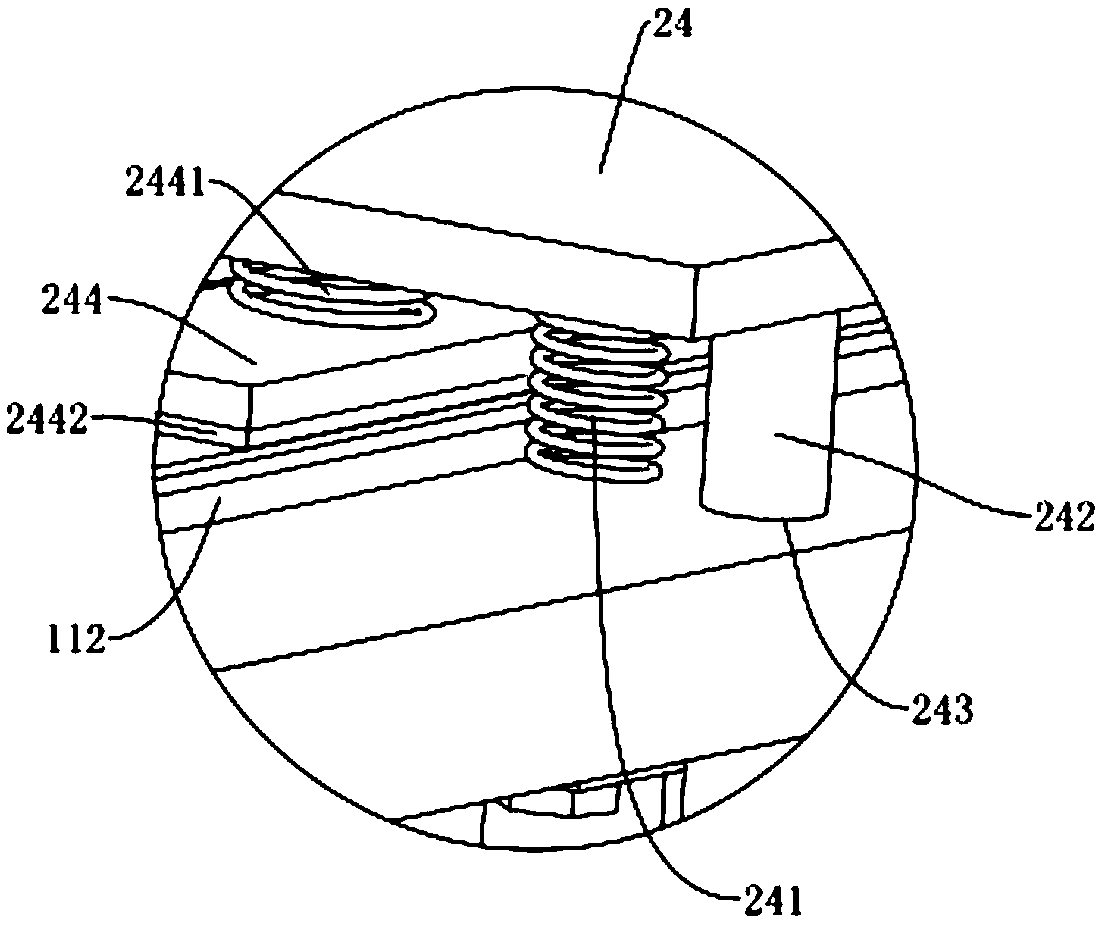

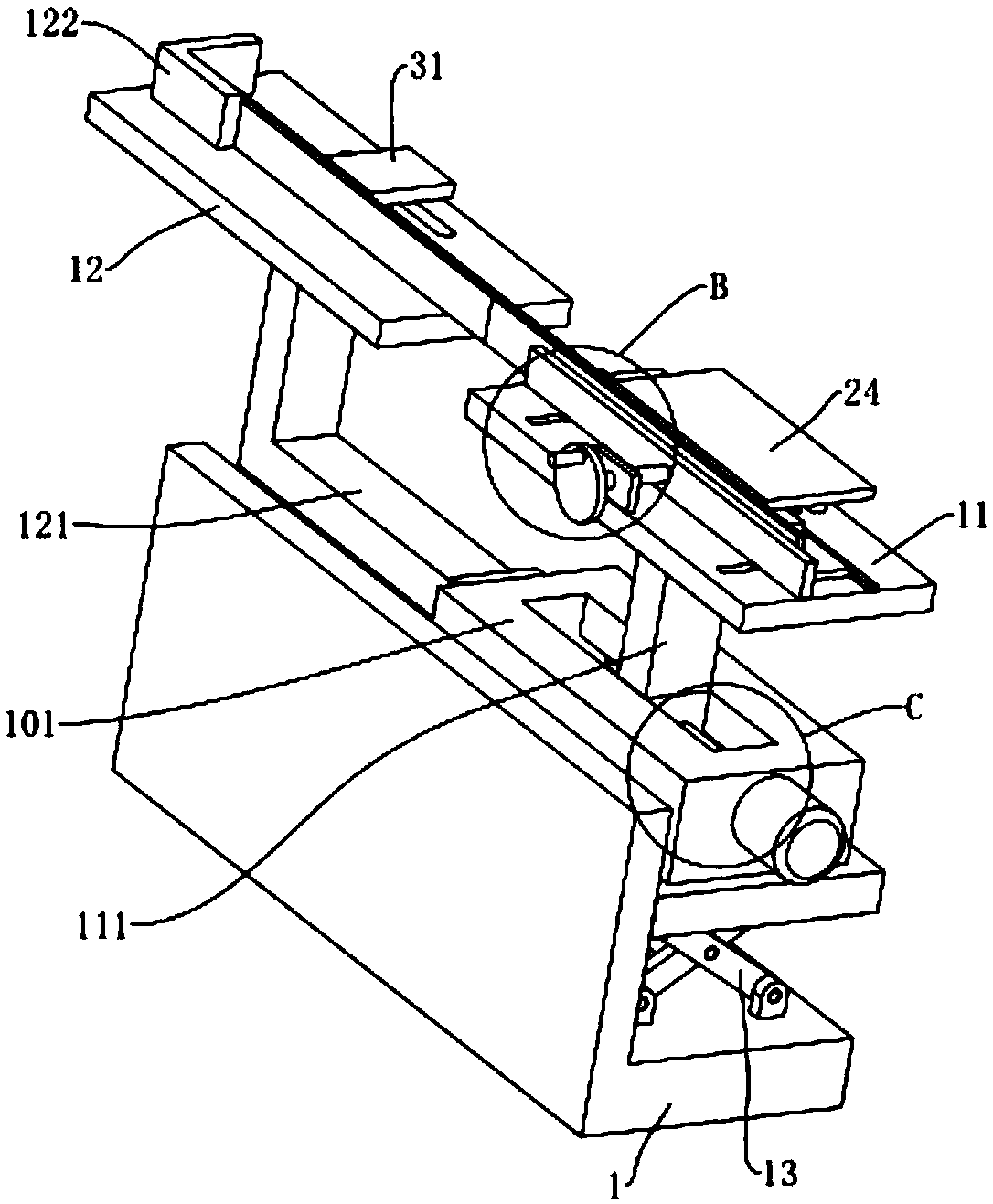

[0046] refer to figure 1 , a steel structure profile welding spacing adjustment work frame, including a base 1 with an L-shaped cross section, in order to facilitate the adjustment of the height of the L-shaped steel to be welded on the device, slide on the base 1 in the vertical direction A fixed plate 10 is connected, and a fixed base 101 is fixed on the fixed plate 10, wherein a first support rod 111 is slidably connected in the horizontal direction above the fixed base 101, and a first support rod 111 is connected to the end of the first support rod 111. The profile placement plate 11 is also disassembled and connected with the second support bar 121 on the fixing seat 101, wherein the second profile placement plate 12 is welded and fixed at the end of the second support bar 121, and the first profile placement plate 11 and the second profile placement plate are placed The plate 12 is used to place two sections of L-shaped steel to be welded, and the two sections of profil...

Embodiment 2

[0055]The difference from Example 1 is that the surfaces of the first profile placement plate 11 and the second profile placement plate 12 are coated with a layer of wear-resistant coating, since the surfaces of the first profile placement plate 11 and the second profile placement plate 12 are Place the surface of the L-shaped steel to be welded, in order to prevent the surface of the first profile placement plate 11 and the second profile placement plate 12 from being scratched prematurely, the surface of the first profile placement plate 11 and the second profile placement plate 12 is coated with a layer of wear-resistant coating, so a method for preparing a wear-resistant coating is provided, which has the advantages of short preparation process and simple preparation, wherein the preparation method of the wear-resistant coating on the surface of the first profile placement plate 11 and the second profile placement plate 12 is as follows :

[0056] Get the following compone...

Embodiment 3

[0062] The difference from Example 2 lies in the preparation of the wear-resistant coating on the surface of the first profile placement plate 11 and the second profile placement plate 12, wherein the preparation method of the wear-resistant coating is as follows:

[0063] Get the following components by weight for subsequent use: 26 parts of nano-magnesium powder, 33 parts of nano-nickel powder, 25 parts of nano-magnesia powder, 24 parts of nano-chromium powder, 21 parts of nano-silicon nitride powder, 12 parts of nano-manganese powder, 12 parts of nano copper powder;

[0064] S1, mixing materials, adding nano-magnesium powder, nano-nickel powder, nano-magnesia powder, nano-chromium powder, nano-silicon nitride powder, nano-manganese powder and nano-copper powder into the powder mixer and mixing for 15 minutes;

[0065] S2, heating, preheating the mixture obtained in S1 to 125°C;

[0066] S3. Perform sandblasting treatment on the surfaces of the first profile placement plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com