Sea sand and shell separating device

A separation device and shell technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of dislocation, low strength, poor adhesion of cement slurry, etc., and achieve the effect of preventing water flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific implementation devices in conjunction with the accompanying drawings.

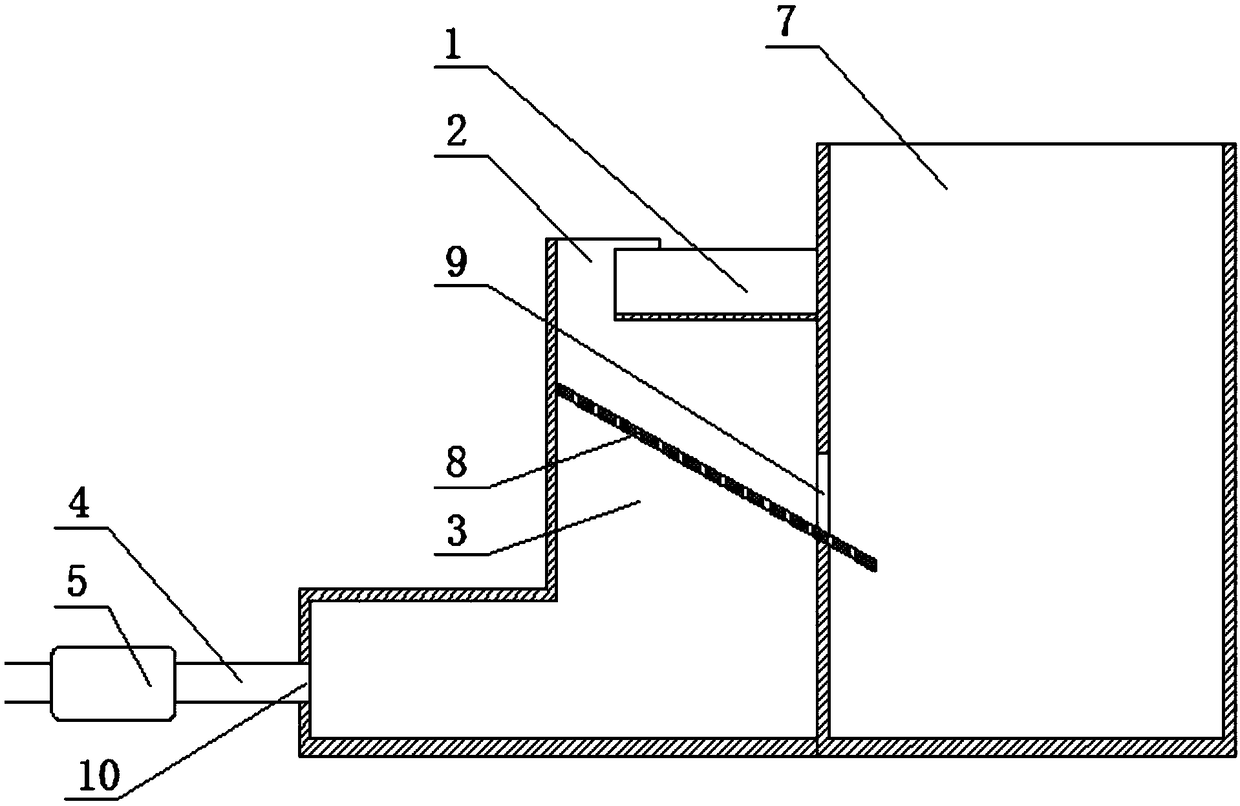

[0041] Such as Figure 1-3 As shown, a sea sand and shell separation device mainly includes a pressurized water tank 3 and a sand collection tank 7, and the pressurized water tank 3 and the sand collection tank 7 are adjacent to each other.

[0042] The top of the pressurized water tank 3 is provided with a "V"-shaped baffle 1, the "V"-shaped baffle 1 is fixedly connected with the inner wall of the pressurized water tank 3, and the length of the "V"-shaped baffle 1 is less than the length of the inner cavity of the pressurized water tank 3, so The rear end of the "V" type baffle plate 1 can form a sand inlet 2 with the inner wall of the rear end of the pressurized water tank 3 . Both sides of the top of the pressurized water tank 3 have a water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com