Photothermal directionally-controlled liquid drop migration polymerization device and using method thereof

A polymerization device and droplet technology, applied in the field of microfluidics, can solve the problems of poor system stability and easy contamination of reagents, and achieve the effects of stable reaction, convenient operation and high specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

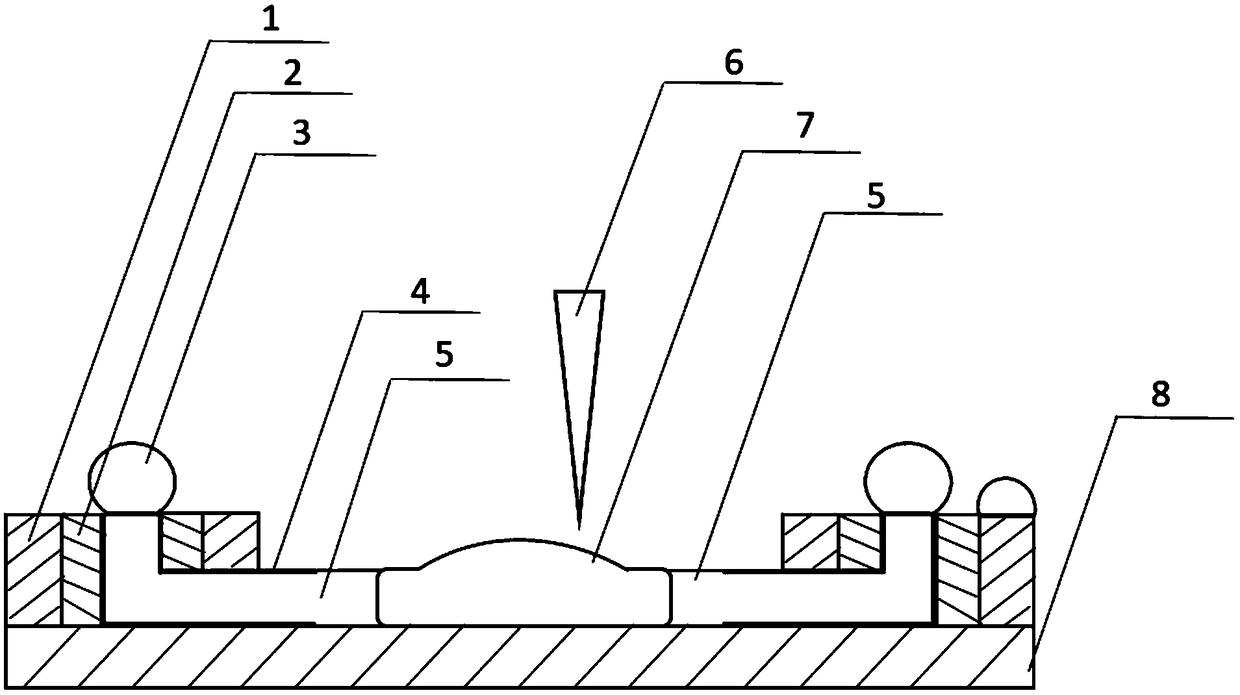

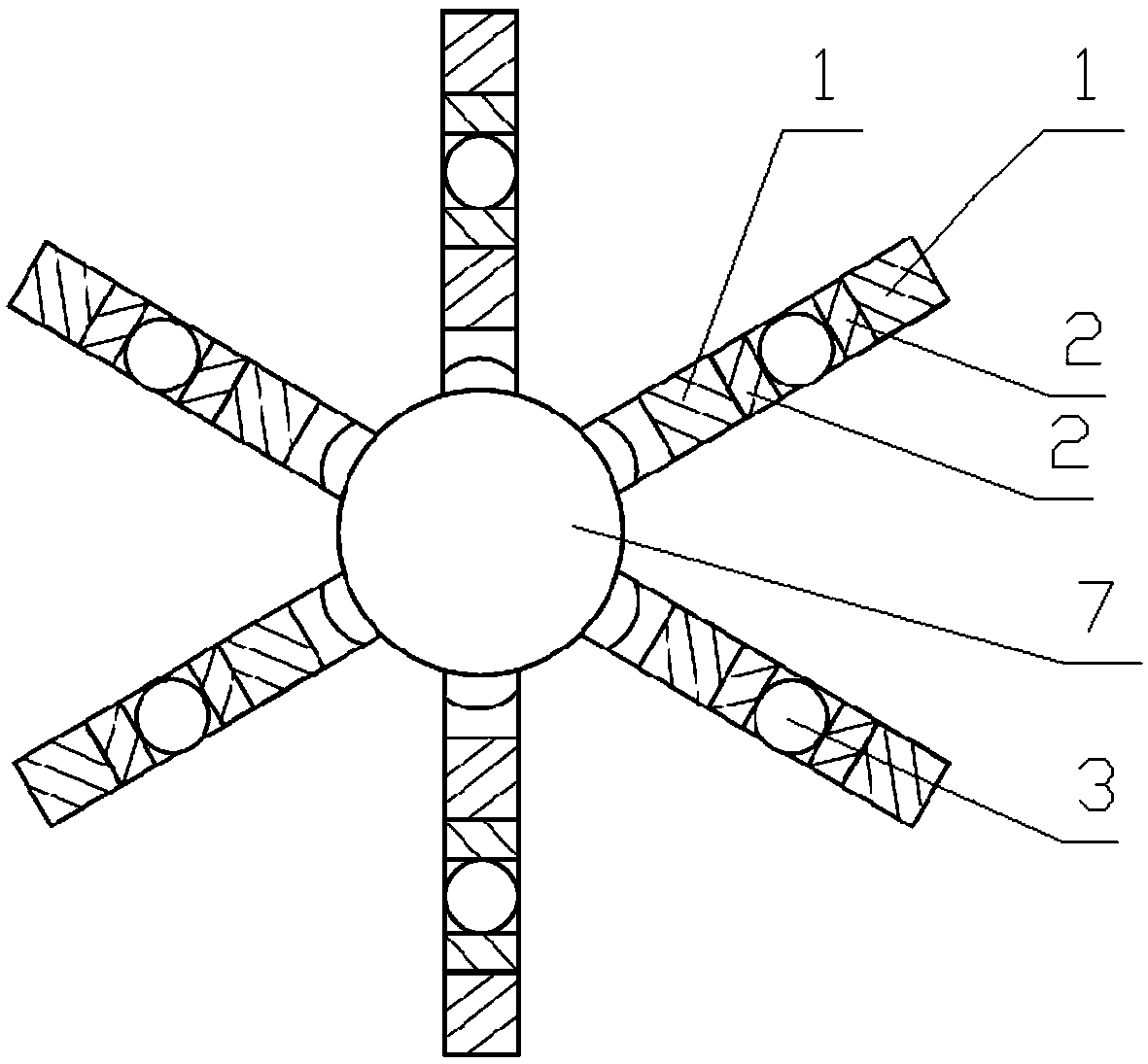

[0036] Such as Figure 1-Figure 2 As shown, the present invention provides a photothermal directional control liquid droplet migration and polymerization device, including a substrate, the central part of the substrate is depressed to form a liquid pool 7, the liquid pool 7 is filled with water, and an infrared laser 6 is arranged above the liquid pool 7. The laser 6 is used to eccentrically heat the water to form steam. The eccentric heating causes the droplets 3 in a specific direction to migrate first, so as to precisely control the migration of the specified droplets 3 and further polymerization reaction. The periphery of the substrate is evenly divided into six cuboids distributed in a divergent shape, and each cuboid is provided with a migration platform. The inside of the substrate is provided with an airflow channel 5 corresponding to the transfer platform for steam flow, which is used to send the steam generated in the liquid pool 7 to the transfer platform, and the a...

Embodiment 2

[0051] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the migration platform is cylindrical. Compared with the first embodiment, this embodiment can satisfy the migration of the droplet 3 in different directions without falling off the substrate and sticking impurities, and avoiding errors caused by the contamination of the droplet 3 .

Embodiment 3

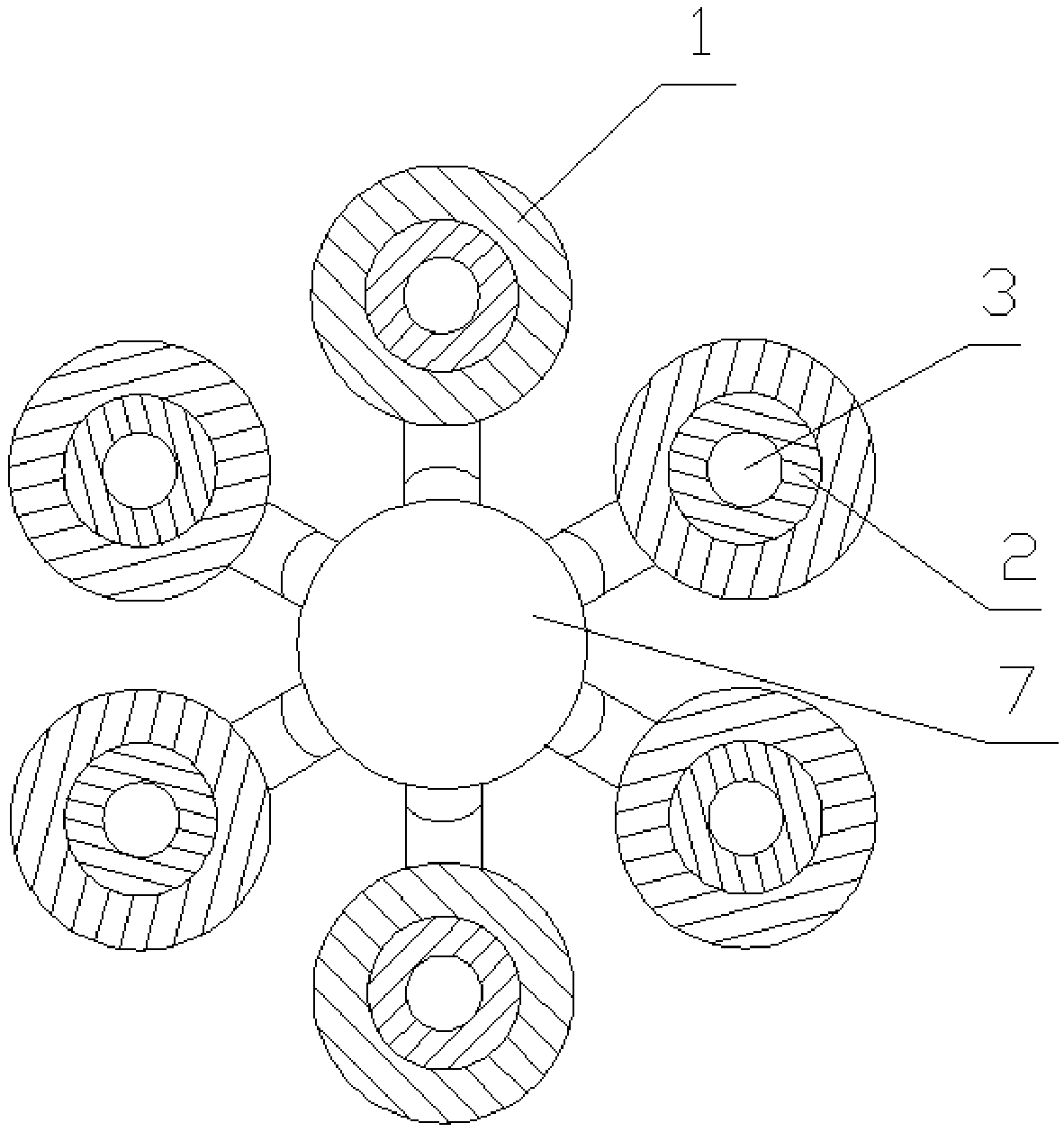

[0053] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment is that the substrate is in the shape of a round cake, and multiple transfer platforms are connected to each other to form a whole. Compared with the first embodiment, this embodiment can prevent the droplet 3 from falling into the gap between the transfer platforms, avoid the droplet 3 from falling out of the substrate and stick impurities, and avoid errors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com