A kind of flue gas dust removal filter bag

A filter bag, flue gas technology, applied in the direction of filtration separation, dispersed particle filtration, separation methods, etc., can solve the problems of insufficient cleaning of secondary dust and destruction of primary dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

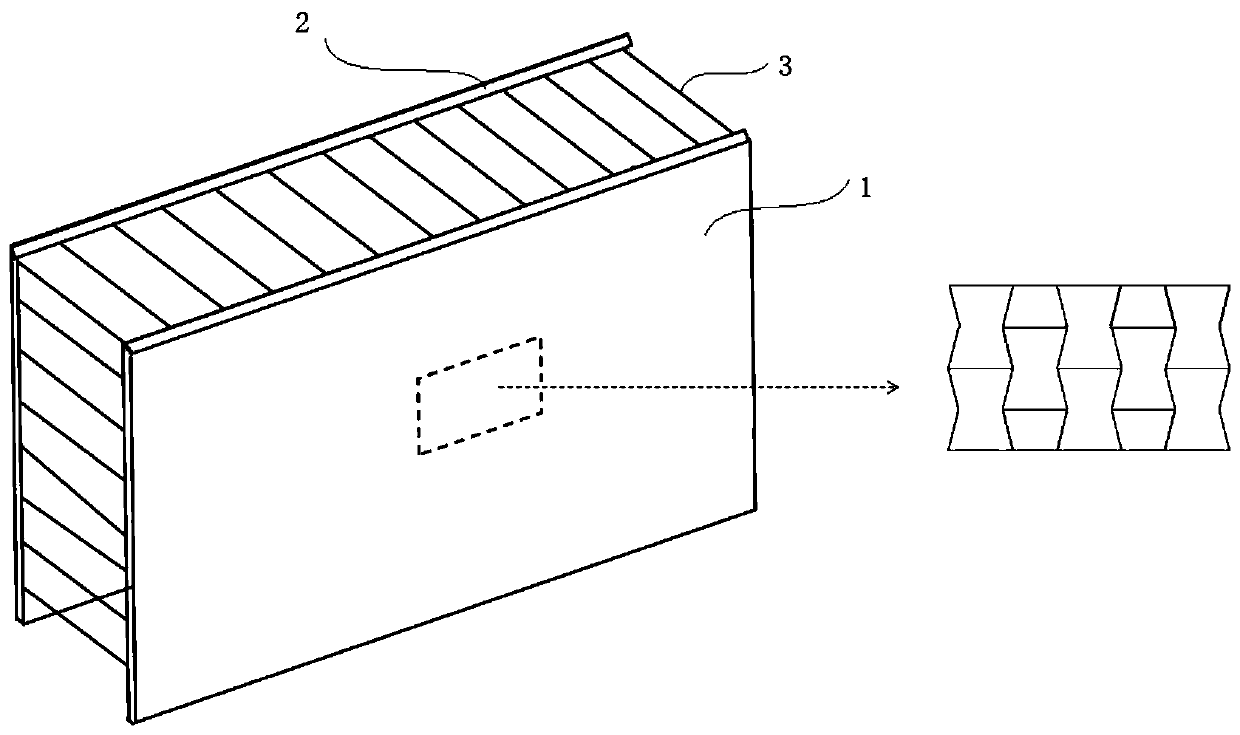

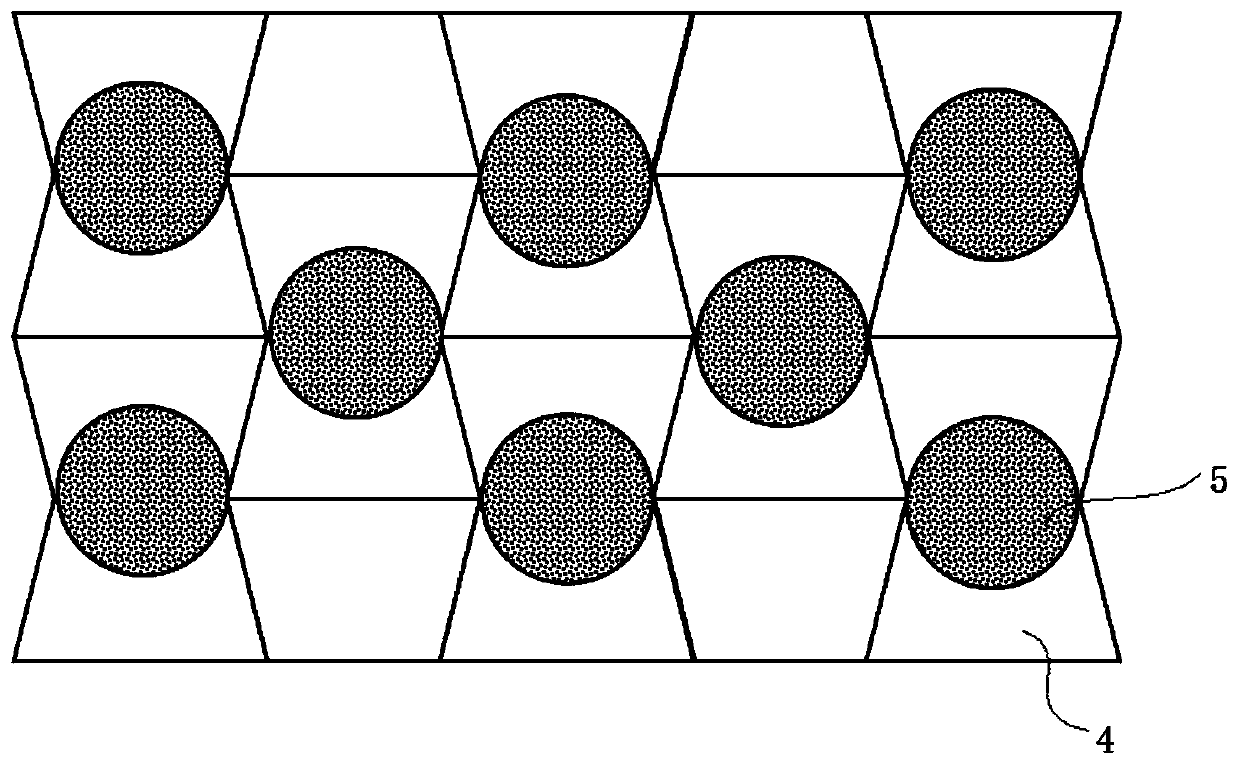

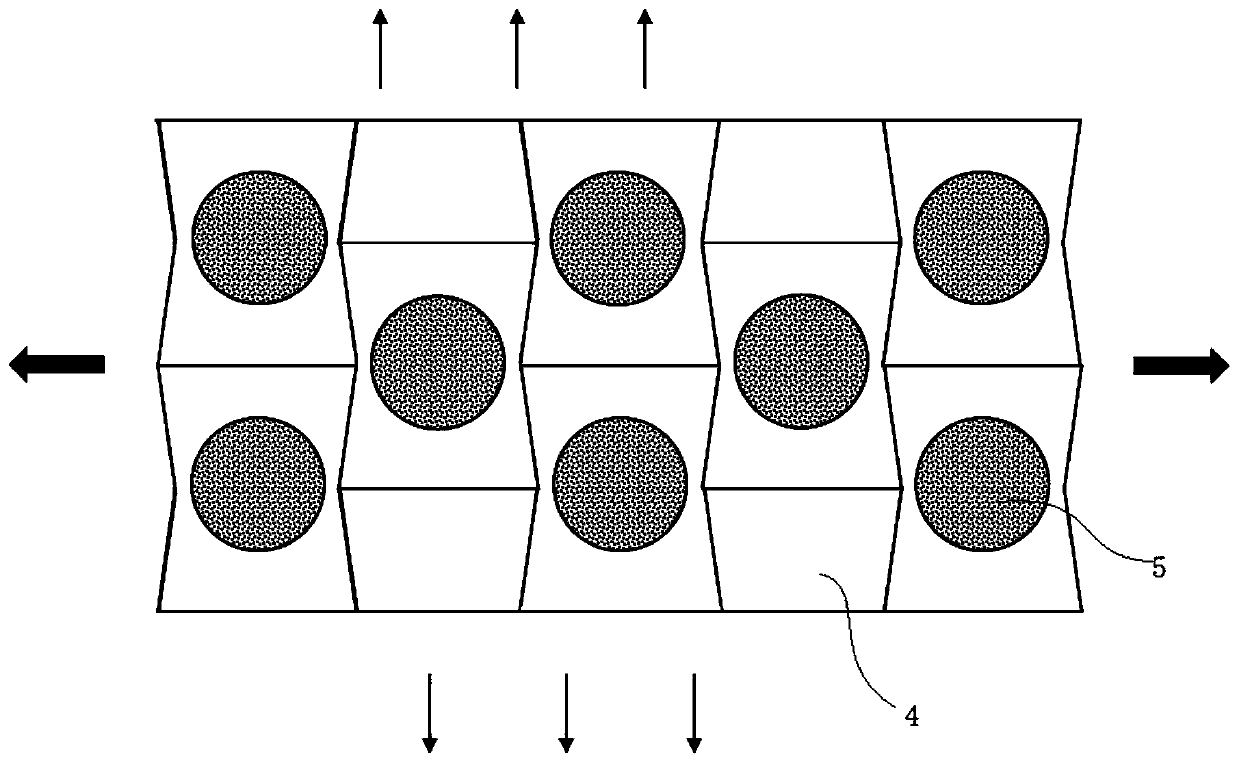

[0049] like figure 1 As shown, a flue gas dust removal filter bag is characterized in that: the filter material for preparing the filter bag has a double-layer structure, and the filter material includes an outer filter cloth 2, an inner filter cloth 1, and is connected to the inner filter cloth 1 and the inner filter cloth. The connection line 3 between the outer filter cloths 2; the inner filter cloth 1 is used as a dust-facing layer, and the inner filter cloth 1 includes a base cloth layer 4 and a fiber mesh layer, and the base cloth layer 4 has a negative Poisson's ratio, The fiber net layer is compounded on the base cloth layer 4 through a needling process.

[0050] Preferably, in the filter material having a double-layer structure, the thickness of the outer filter cloth 2: the thickness of the inner filter cloth 1: the length of the conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com