Novel cigarette suitable for different smoking modes and preparing method thereof

A production method and a new technology, applied in the directions of tobacco, application, preparation of tobacco, etc., can solve the problems of satisfactory smoking effect, difficulty in producing smoke and taste, and inability to consumers, and achieve novel and beautiful structure of cigarettes and rich aroma of cigarettes. , Improve the effect of single aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The papermaking method is used to reconstitute the tobacco leaf production process, and the tobacco leaves are extracted, concentrated, solid-liquid separated, sheet-formed, coated and dried. After concentrating the tobacco leaf extract, add a glycoside compound with a mass ratio of 30% of the extract, and after about 20 minutes of mixing and concentration reaction, the coating liquid is obtained, and the coating liquid is added to the paper-making molding during the coating process. In the base sheet, a reconstituted smoked sheet is obtained.

Embodiment 2

[0025] The paper-making method is used to reconstitute the tobacco leaf production process, and the mixture of tobacco leaves and tobacco stems is extracted, concentrated, solid-liquid separated, sheet-formed, coated and dried. Add sugar ester compound and 20% terpene compound in the mass ratio of the extract to the later stage of concentrating the extract of the tobacco leaf and tobacco stem mixture, and obtain the coating liquid after mixing and concentrating for about 20 minutes. The coating liquid is added to the paper-formed base sheet in the coating process to obtain the reconstituted cigarette sheet.

Embodiment 3

[0027] The papermaking method is used to reconstitute tobacco leaf production technology, and the tobacco raw materials are extracted, concentrated, solid-liquid separated, sheet-formed, coated and dried. After concentrating the tobacco raw material extract, add 15% of the Amadori compound and 5% of the lipid compound in the mass ratio of the extract, and obtain a coating solution after mixing and concentrating for about 20 minutes. The cloth process is added to the base sheet of the paper-forming shape to obtain the reconstituted smoke sheet.

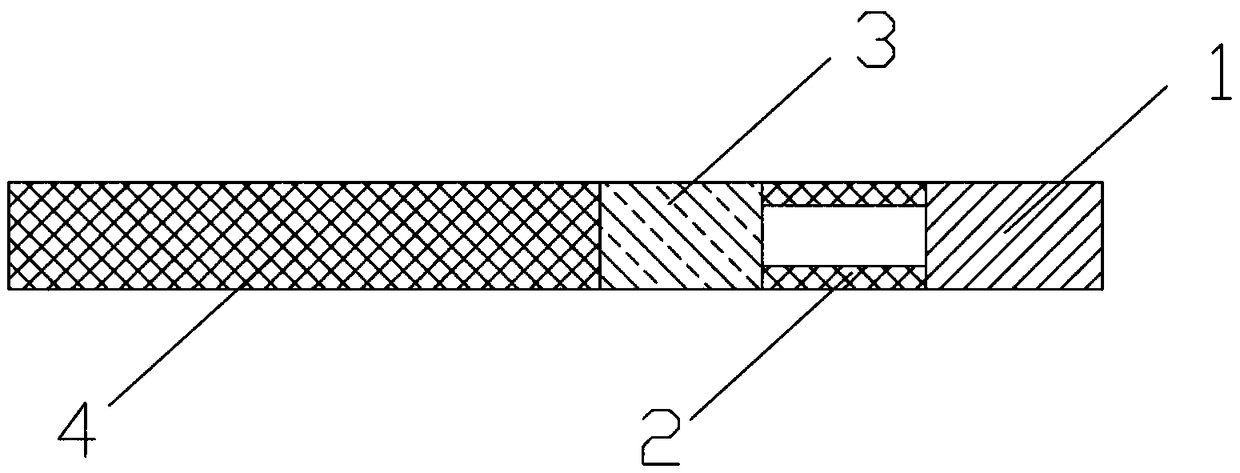

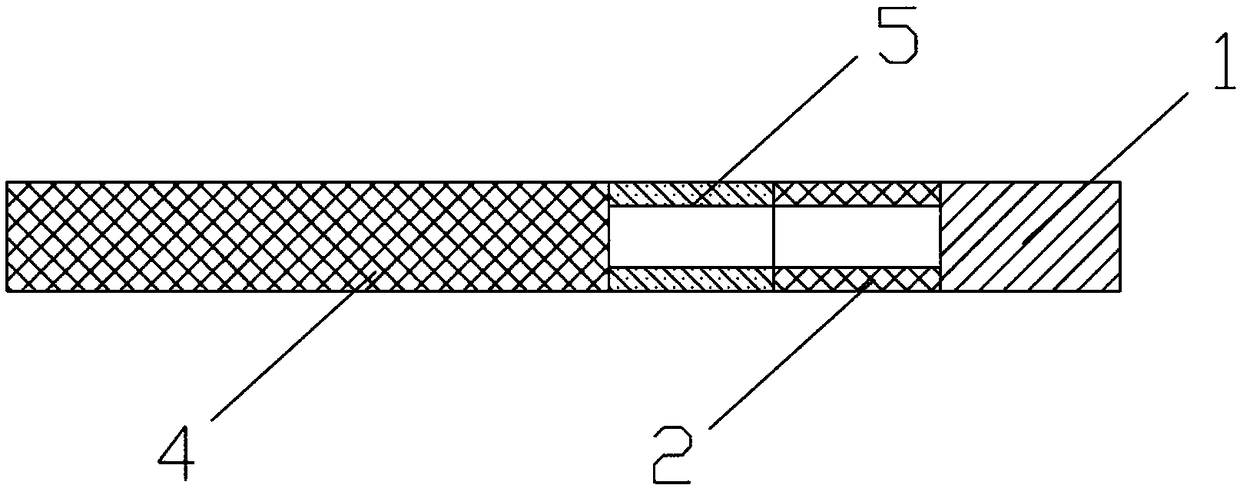

[0028] When using the burning and sucking method to smoke, light the shredded tobacco section 4 of the new cigarette, and use the outer end of the shredded tobacco section 1 as the lip end to perform normal smoking. When using a heat-not-burn appliance, manually remove part or all of the shredded tobacco section 4, insert the reconstituted shredded tobacco section 1 into the heat-not-burn appliance, and use the shredded tobacco section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com