A dedicated rotary kiln for pyrolysis oxidation of solid waste salt

A technology of solid waste salt and rotary kiln, applied in rotary drum furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of inability to effectively separate toxic and harmful substances, low heat exchange efficiency of devices, corrosion damage, etc., and improve service life. , The effect of improving transportation speed, convenient maintenance and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

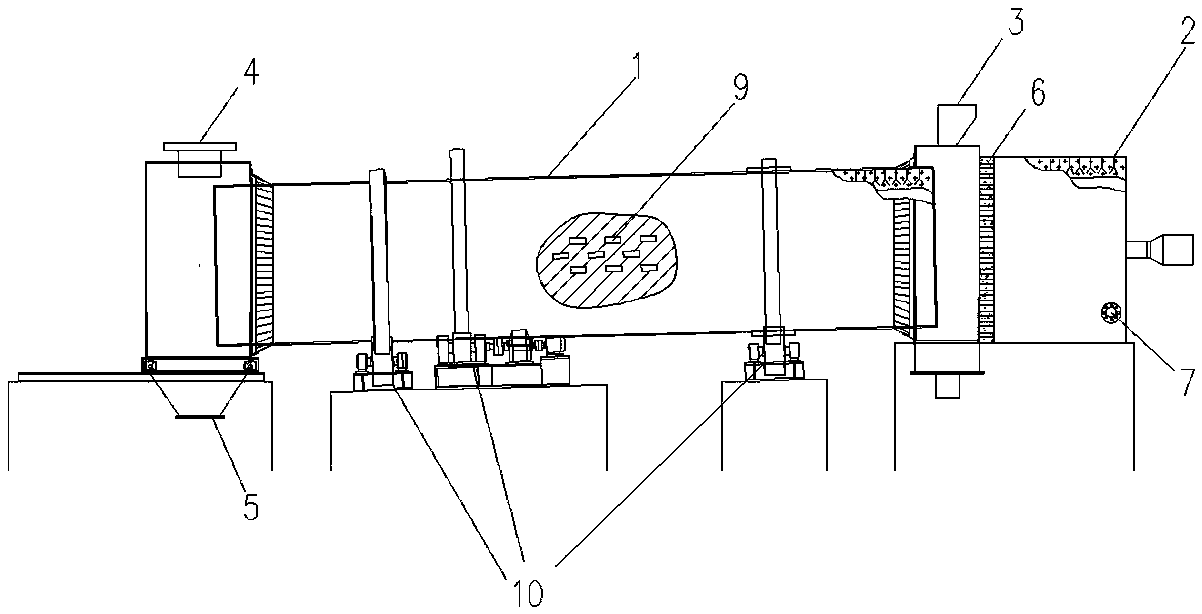

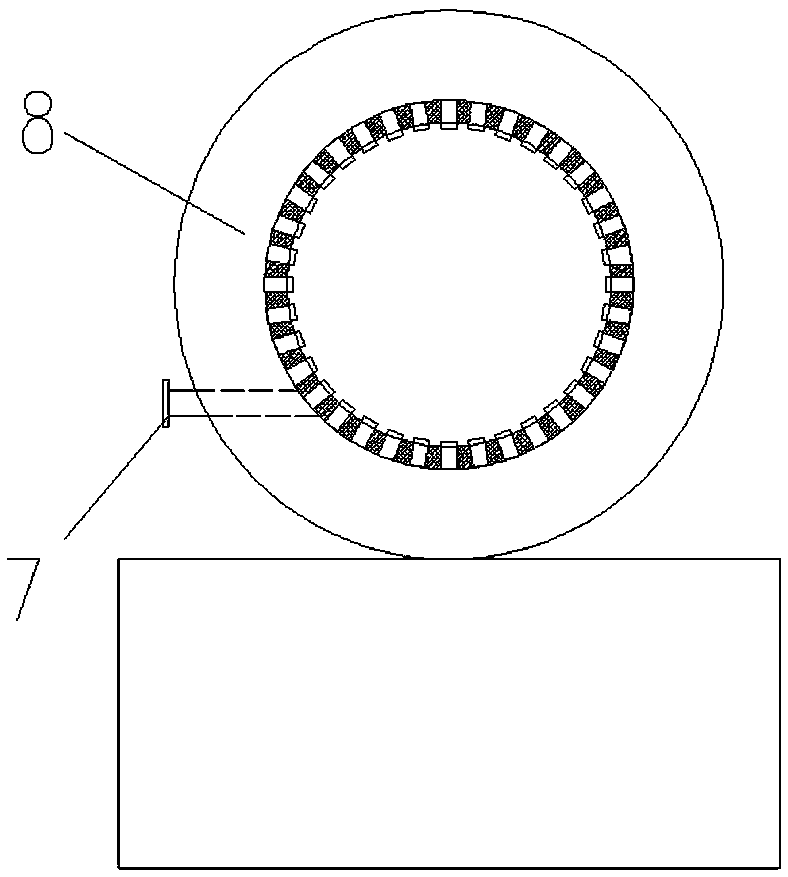

[0019] A special rotary kiln for pyrolysis and oxidation of solid waste salt. The front end of the rotating cylinder 1 is connected to the heating furnace 2. The top of the front end of the rotating cylinder 1 is equipped with a feeding hopper 3. The top and bottom of the rear end of the rotating cylinder 1 are respectively equipped with smoke The gas outlet 4 and the slag outlet 5, and the combustion chamber of the heating furnace 2 connected to the rotating cylinder 1 have a built-in regenerative porous fire-blocking wall 6, the regenerative porous fire-blocking wall 6 is a refractory brick wall, and the refractory brick wall is set There are several flue gas passage holes, the regenerative porous fire-blocking wall 6 isolates the combustion chamber of the rotating cylinder 1 and the heating furnace 2, and there is a gap between the regenerative porous fire-blocking wall 6 and the cylinder below the feeding hopper 3, usually Control at more than 30cm to ensure safety; the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com