Container with management function

A container and container body technology, which is applied in the field of plate containers, can solve the problems of troublesome taking out plates, the container does not have the function of management, etc., and achieves the effect of convenient storage, access and improved management convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

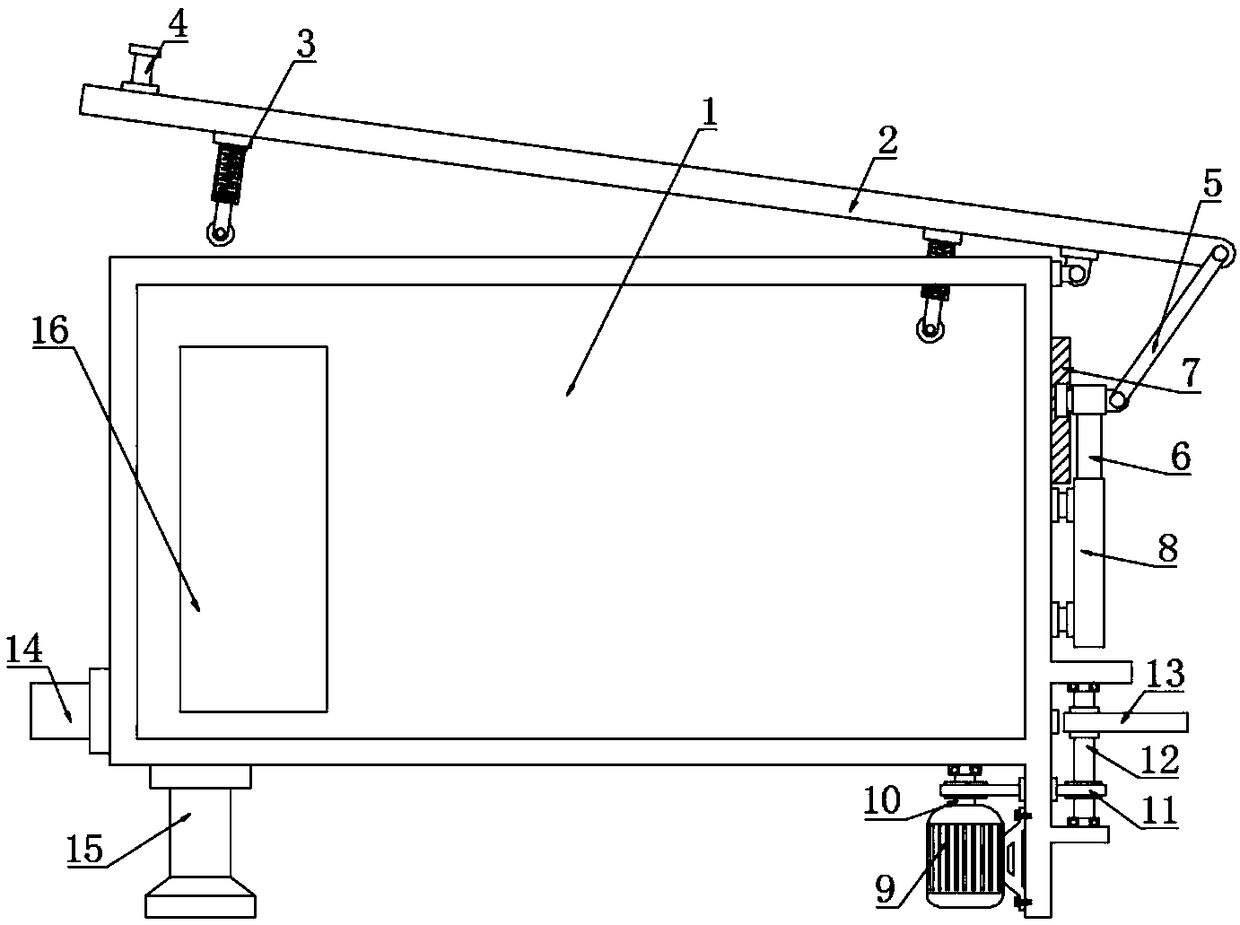

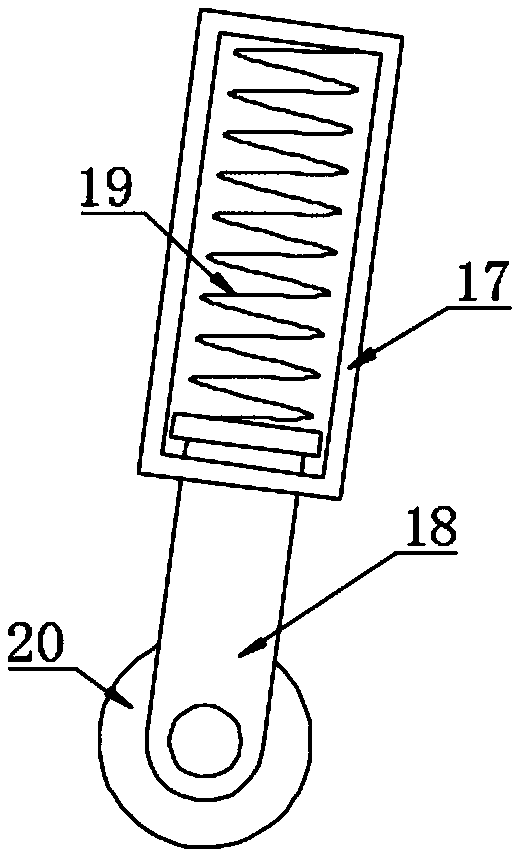

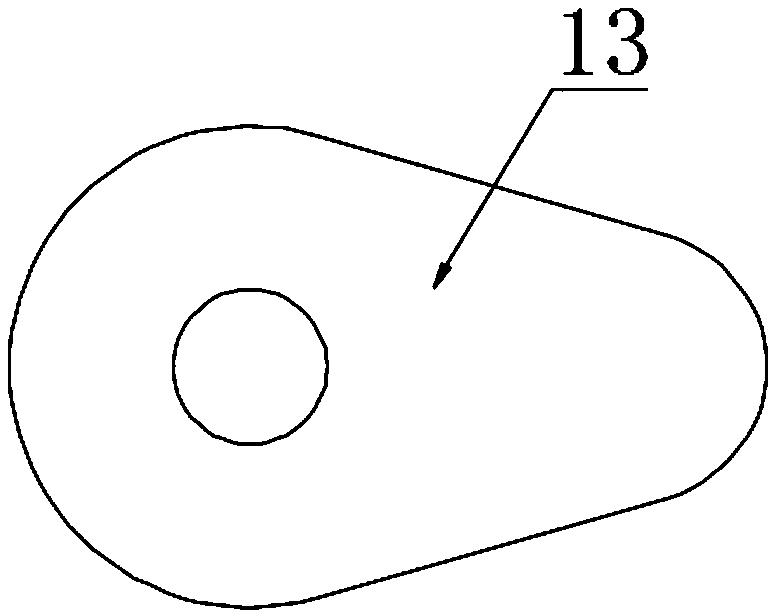

[0020] see Figure 1-3 , in Embodiment 1 of the present invention, a manageable container includes a container body 1, a stabilizing device 3, a cylinder 8, a drive motor 9, a cam 13, and a discharge chute 14; the upper part of the container body 1 is provided with an upper cover plate 2 , the lower surface on the right side of the upper cover plate 2 is hinged with the container body 1, and the right end of the upper cover plate 2 is rotated to connect the upper end of the connecting rod 7, and the lower end of the connecting rod 7 is rotatably connected to the upper end of the piston rod 6; the lower part of the piston rod 6 is connected to the cylinder 8 by sealing and sliding , the cylinder 8 is fixedly connected to the container body 1, and the inner side of the upper part of the piston rod 6 slides to connect with the chute 7. The chute 7 is arranged on the right side wall of the container body 1, and the air pressure in the control cylinder 8 drives the piston rod 6 up a...

Embodiment 2

[0023] see Figure 1-3 , in Embodiment 2 of the present invention, a manageable container includes a container body 1, a stabilizing device 3, a cylinder 8, a drive motor 9, a cam 13, and a discharge trough 14; the upper part of the container body 1 is provided with an upper cover plate 2 , the lower surface on the right side of the upper cover plate 2 is hinged with the container body 1, and the right end of the upper cover plate 2 is rotated to connect the upper end of the connecting rod 7, and the lower end of the connecting rod 7 is rotatably connected to the upper end of the piston rod 6; the lower part of the piston rod 6 is connected to the cylinder 8 by sealing and sliding , the cylinder 8 is fixedly connected to the container body 1, and the inner side of the upper part of the piston rod 6 slides to connect with the chute 7. The chute 7 is arranged on the right side wall of the container body 1, and the air pressure in the control cylinder 8 drives the piston rod 6 up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com