Compound type multifunctional transport case

A transport box and multi-functional technology, applied in the field of composite multi-function transport boxes, can solve the problems of damaged items in the box, waste of resources, single function of the bottom plate, etc., and achieve the effect of solving the drainage problem, avoiding the decay of items, and protecting the functional layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with specific embodiments.

[0043] The structural form of a kind of composite multifunctional transport case in the present embodiment is:

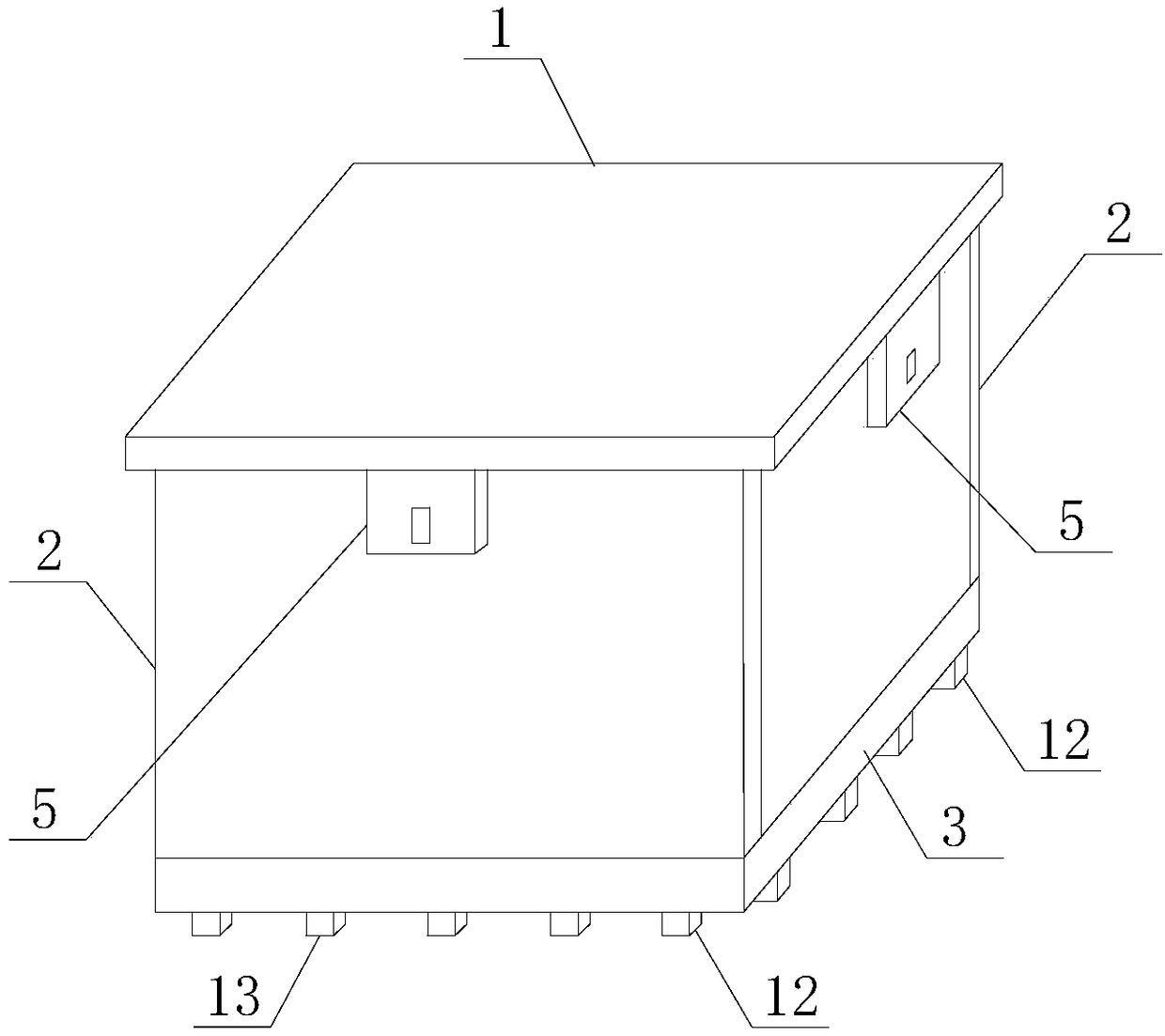

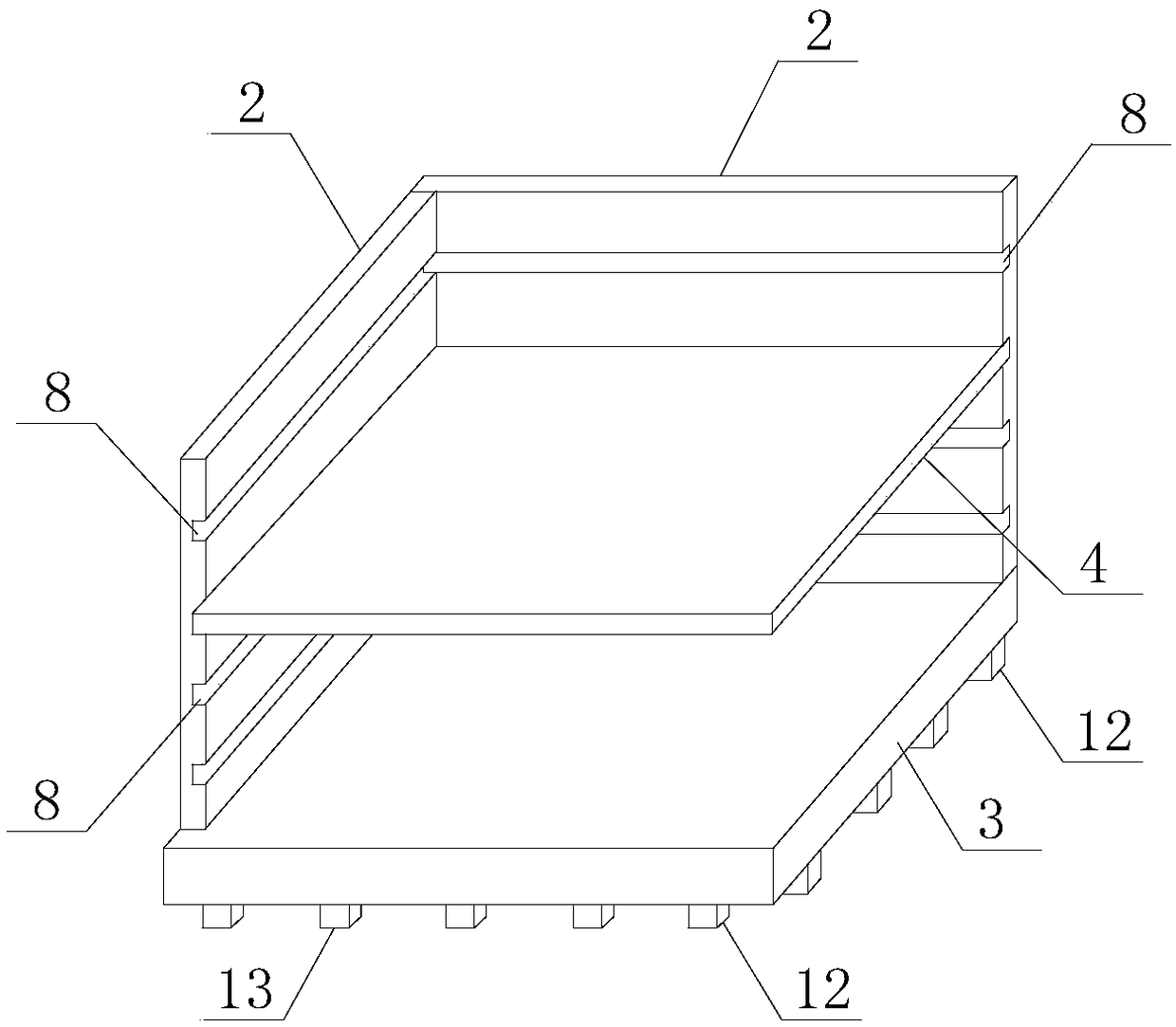

[0044] see figure 1 and figure 2 , The transport box in this embodiment includes a cover plate 1, a side plate 2, a composite box bottom 3 and a compartment storage plate 4.

[0045] see image 3 , in this embodiment, one side of the cover plate 1 is provided with a connecting buckle plate 5 and a cover plate positioning groove 6 for fixing the side plate 2 .

[0046] see Figure 4, in this embodiment, a rotating connecting buckle 7 is provided on one side of the side plate 2. After the top of the side plate 2 is embedded in the positioning groove 6 of the cover plate, the connecting buckle plate on the cover plate 1 is connected by the rotating connecting buckle 7 and the connecting buckle on the cover plate 1. 5 for connection and fixation, on the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com