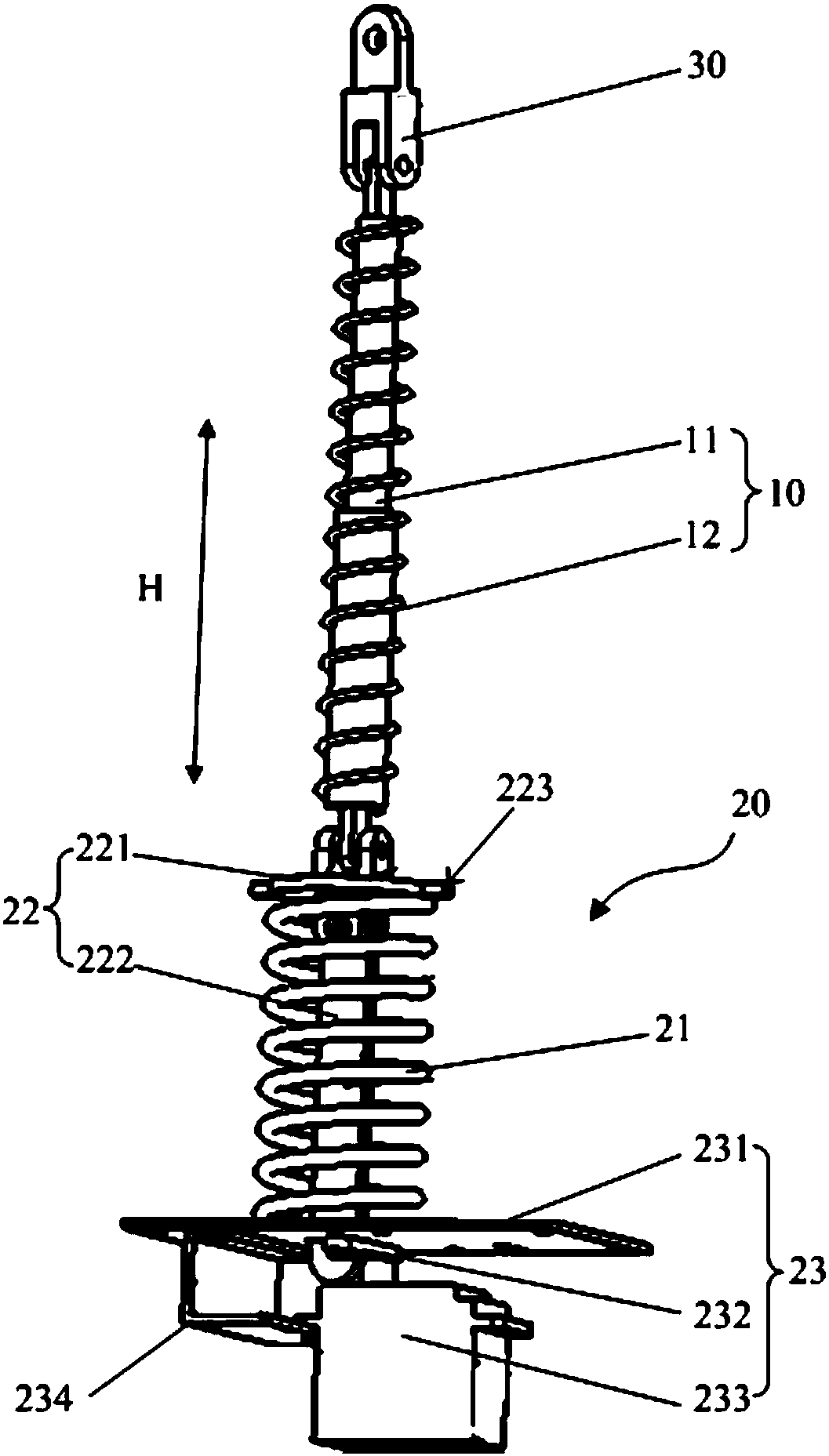

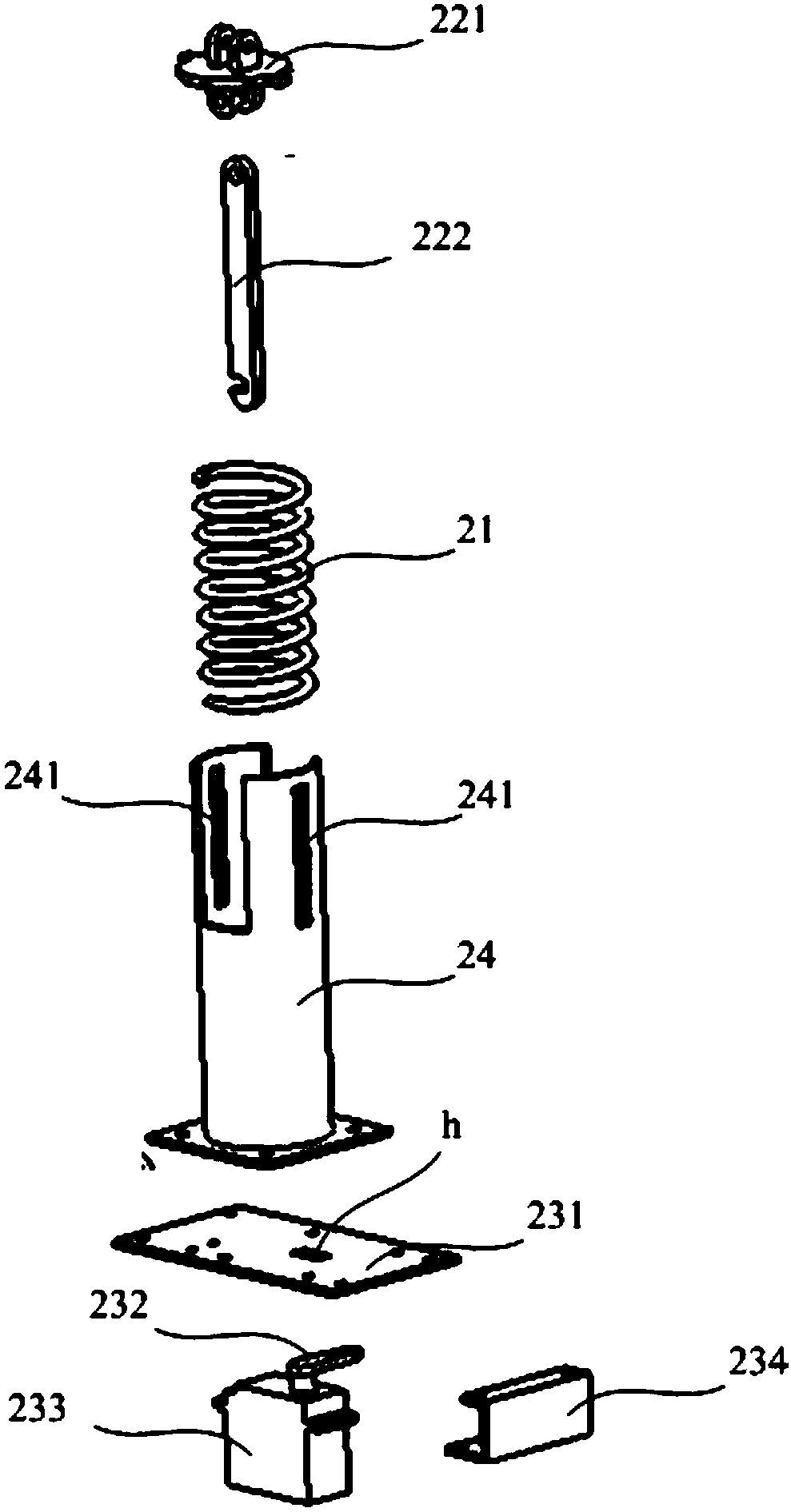

Suspension and energy storage spring type chassis lifting mechanism thereof

An energy storage spring and chassis technology, which is applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of low side impact safety and low safety of ordinary passenger cars, and achieves the goal of improving side impact safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In traditional technology, the basic function of the suspension is to transmit force and moment between the wheel and the frame, and buffer the impact force transmitted to the frame or body from the uneven road, and attenuate the vibration caused by it, so as to ensure the smoothness of the car. Driving, and determines the stability, comfort and safety of the car. All existing suspension systems basically serve this purpose. Among them, there are some suspensions that use air springs, oil-pneumatic springs, etc. as shock absorbers. This type of shock absorber can adjust the stiffness and damping of the shock absorber by changing the amount of internal air and oil-gas compression, thereby slightly adjusting the body and Maintain the posture of the body and ensure stable driving. The shock absorber can adjust the hardness of the air spring and oil-gas spring of the suspension according to the working conditions of the car during driving, so as to prevent some situations t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com