Concrete prefabricated part formwork, concrete prefabricated part formwork platform and concrete prefabricated part forming method

A technology for concrete prefabricated parts and molding methods, applied in ceramic molding machines, ceramic molding linings, molds, etc., can solve the problems of high production cost, low production efficiency, and high cost, and avoid uneven color, high production efficiency, and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

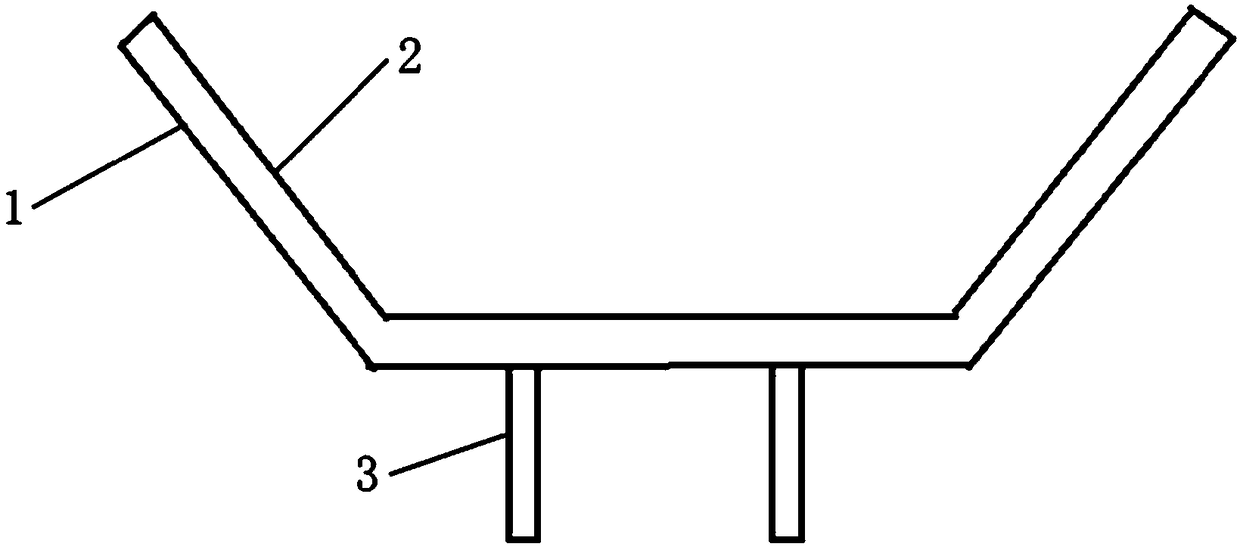

[0025] Specific embodiments of the concrete precast part formwork of the present invention, such as figure 1 As shown, the precast concrete formwork includes a frame 1 and a precast concrete formwork 2 covering the frame 1, and a support column 3 is supported on the ground or other supporting surfaces. The structure of precast concrete formwork 2 is as figure 2 As shown, the concrete preform template 2 adopts a steel plate 4 made of Q345 steel. The steel plate 4 has a polished surface 51 formed by polishing, and the polished surface 51 forms a plate surface for forming the preform. The flatness of the polished surface 51 is 0.3mm / m 2 , The roughness is F5. The thickness of the steel plate 4 is 10 mm, and the thickness of the polished portion 5 is 0.3 mm. In practical applications, the thickness of the steel plate 4 can be selected according to the number of times of use. For castings less than 80 times, a steel plate with a thickness of 8mm can be used, and for castings over ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com