Omnibearing multi-angle industrial robot

An omni-directional and multi-angle technology, applied in the industrial field, can solve the problems of limited range of motion of the robot, poor flexibility of the robot, and inability to move at will. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

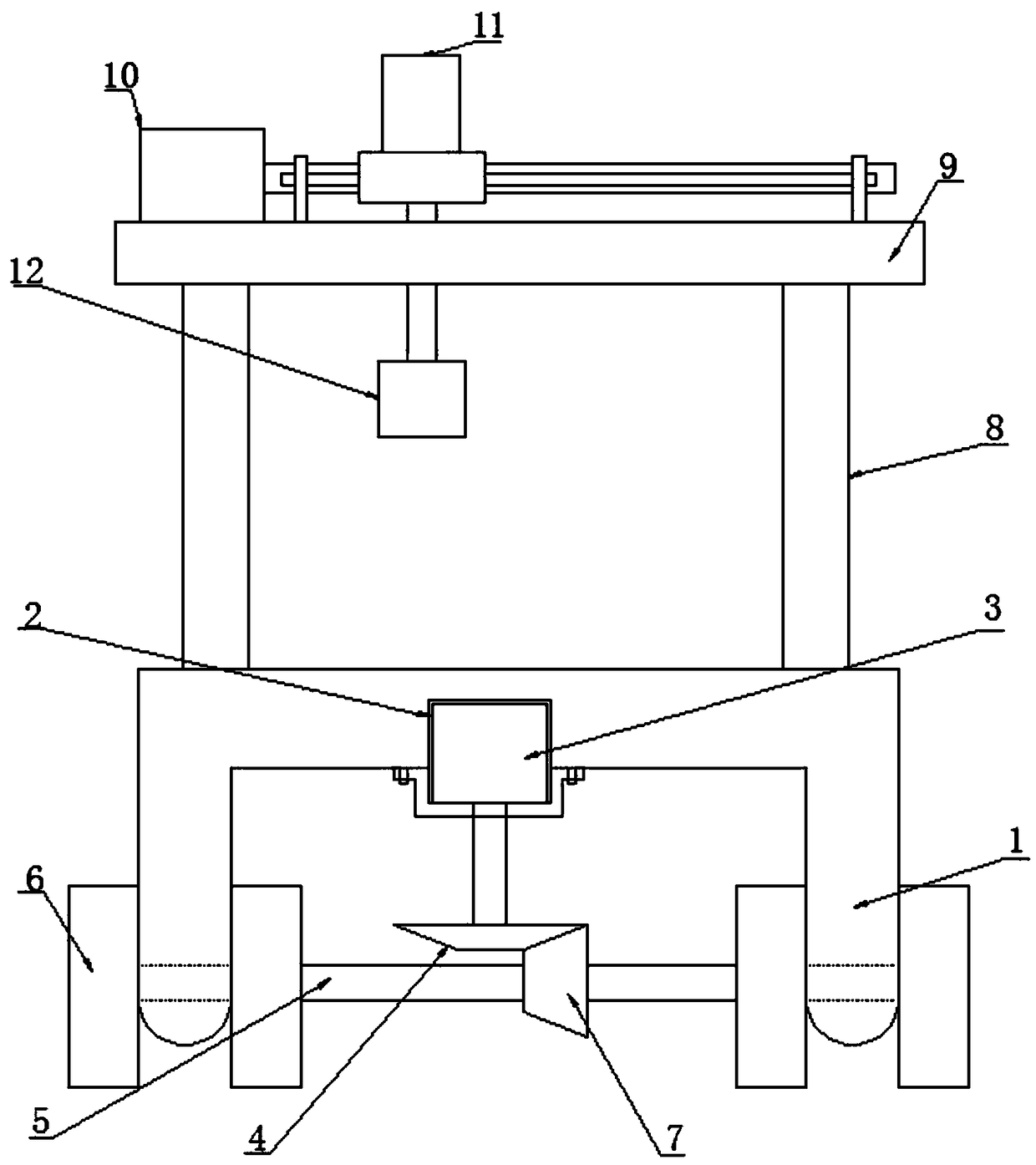

[0028] like Figure 1-5 As shown, the industrial all-round multi-angle robot according to the embodiment of the present invention includes a base 1, the base 1 is an inverted U-shaped structure, and the middle position of the U-shaped groove of the base 1 is provided with a groove 2, so The inside of the groove 2 is provided with a motor 3, the bottom end of the output shaft of the motor 3 is provided with a bevel gear 4, the base 1 is penetrated with a connecting shaft 5, and the connecting shaft 5 is sleeved There are several moving wheels 6 located at the bottom of the base 1, and the middle position of the connecting shaft 5 is sleeved with a bevel gear 2 7 meshed with the bevel gear 1 4, and the top of the base 1 is two A support plate 8 is provided symmetrically on the side, and the top ends of adjacent support plates 8 are connected by a cross plate 9, and the top end of the cross plate 9 is provided with a transmission mechanism 10 and a swing mechanism 11 located on o...

Embodiment 2

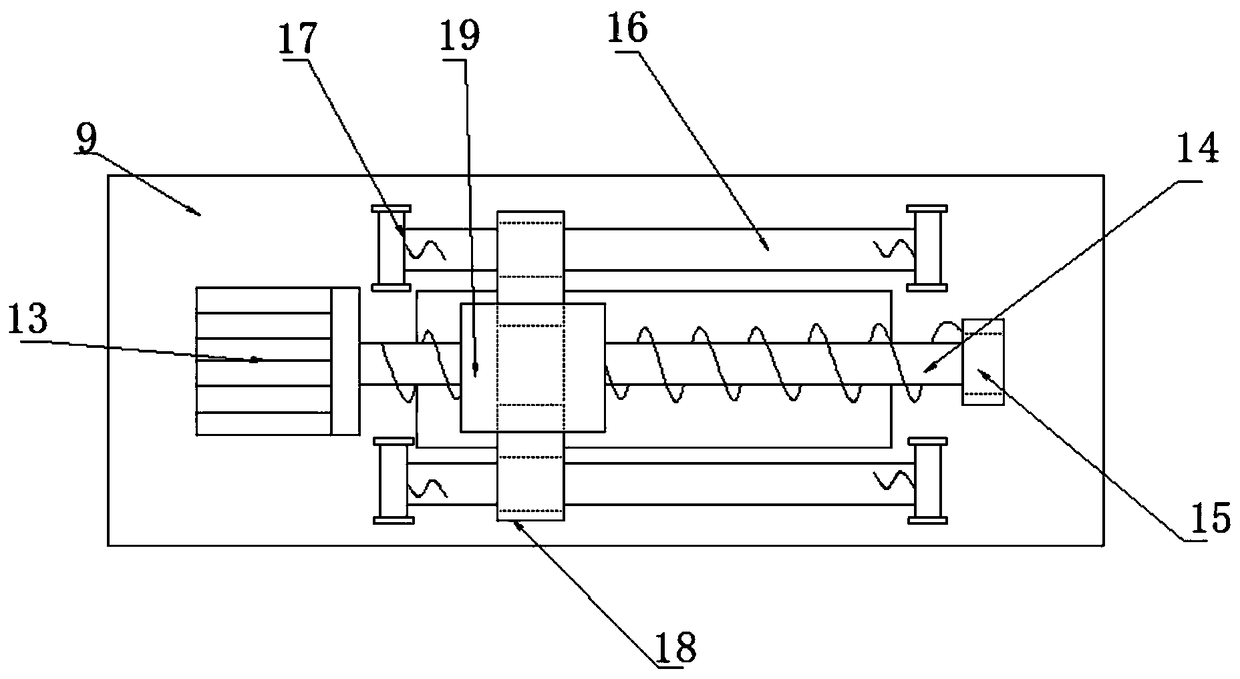

[0031] like figure 2 As shown, buffer springs are fixedly connected to the side of the card seat 2 17 close to the sliding seat 18 . The collision force between the sliding seat 18 and the card seat 2 17 is effectively alleviated by the provided buffer spring.

[0032] like figure 2 As shown, the inner middle position of the sliding seat 18 is provided with a threaded hole compatible with the screw rod one 14, and the inner sides of the sliding seat 18 are symmetrically provided with holes matching the sliding rod 16. the chute. Through the provided threaded holes, the movement of the sliding seat 18 is effectively facilitated.

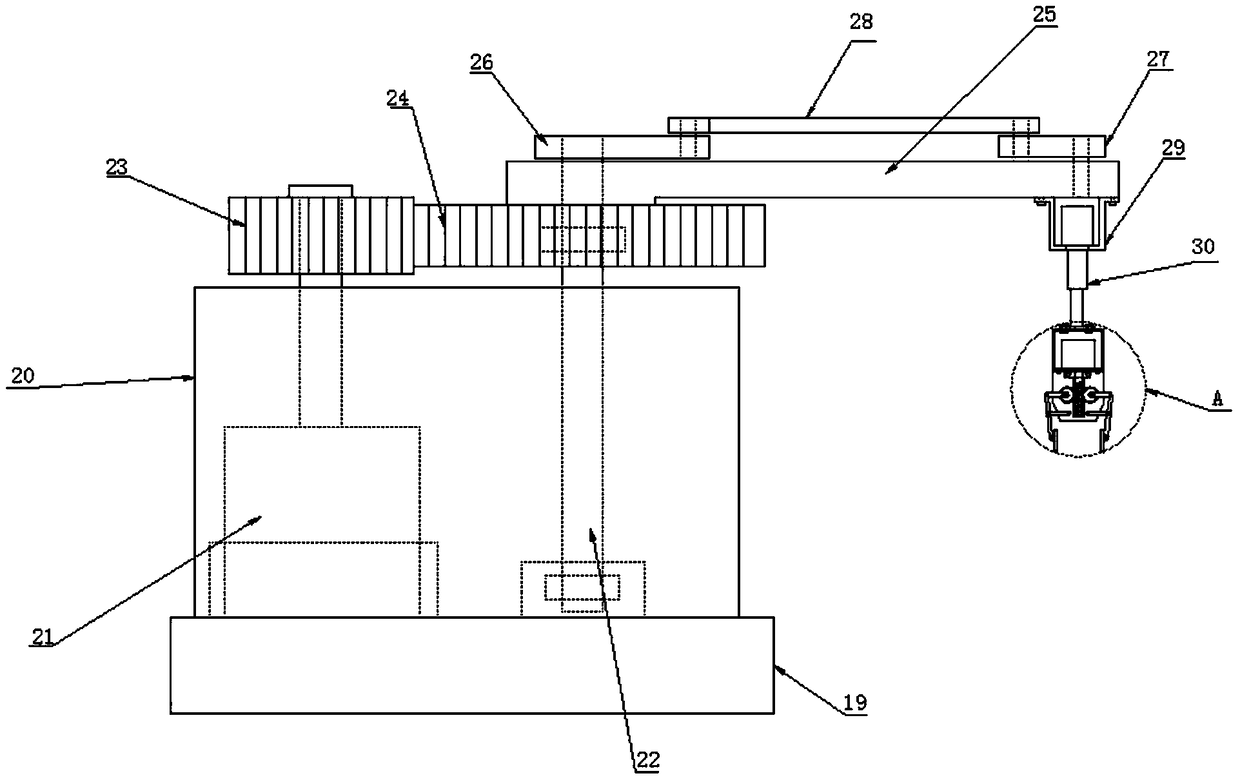

[0033] like image 3 , 4As shown, the swing mechanism 11 includes an installation box 20 arranged on the top of the installation base 19, the inside of the installation box 20 is provided with a motor three 21 and a rotating shaft 22 located on one side of the motor three 21, the The output shaft of the motor three 21 is sleeved with a rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com