A drilling device for integrated stove stainless steel plate

A drilling device, stainless steel technology, used in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve problems such as unfavorable physical and mental health of operators, limiting the processing rate of drilling devices, poor operating workshop environment, etc. problem, to achieve the effect of continuous drilling operation, good fume extraction effect and space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

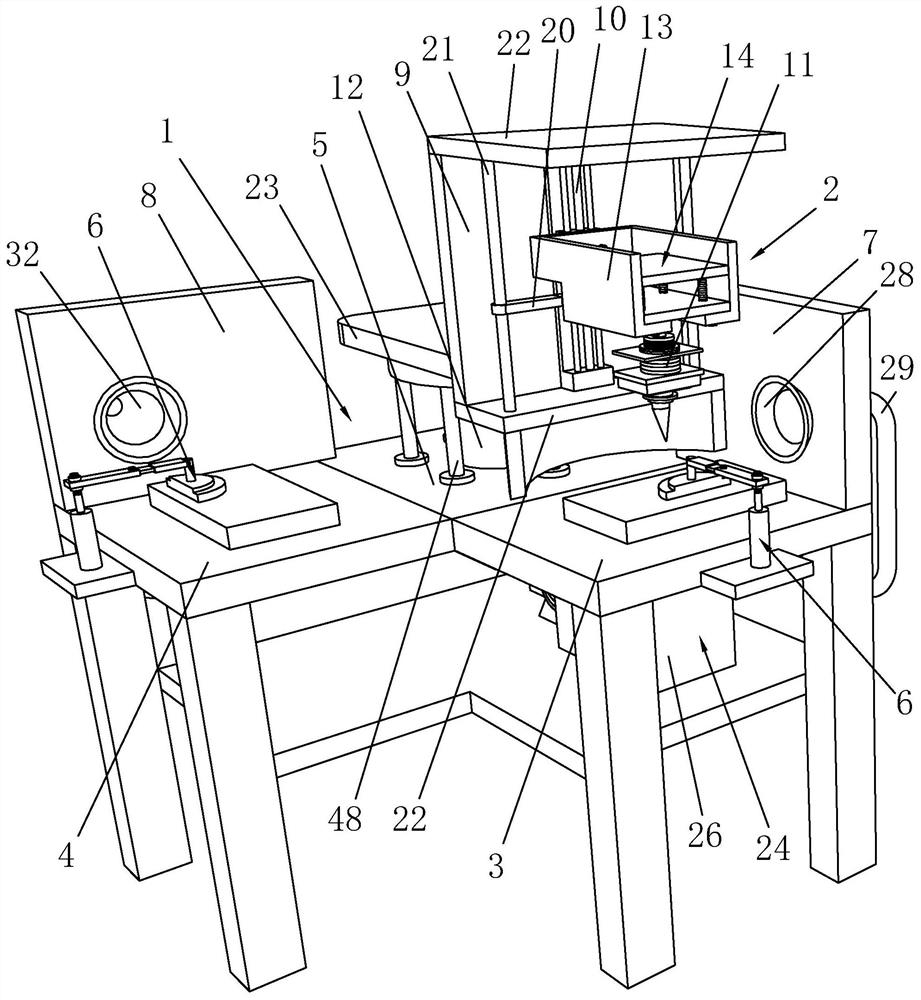

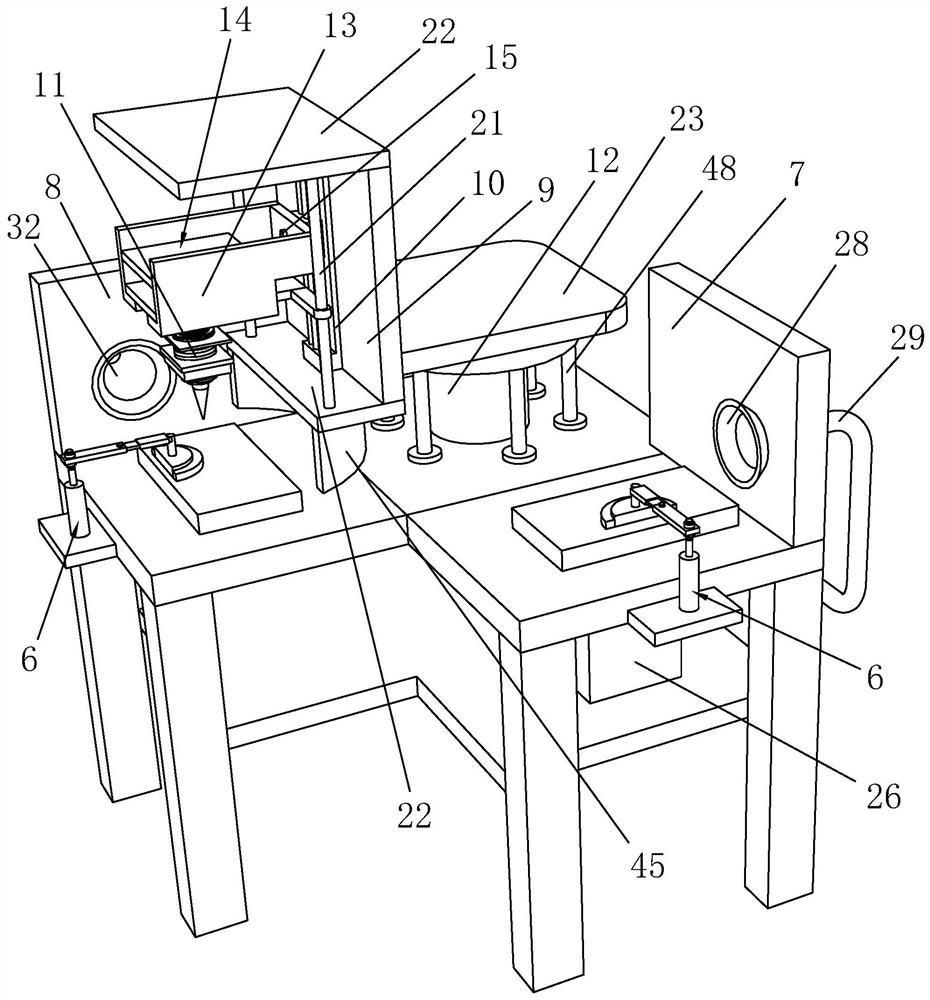

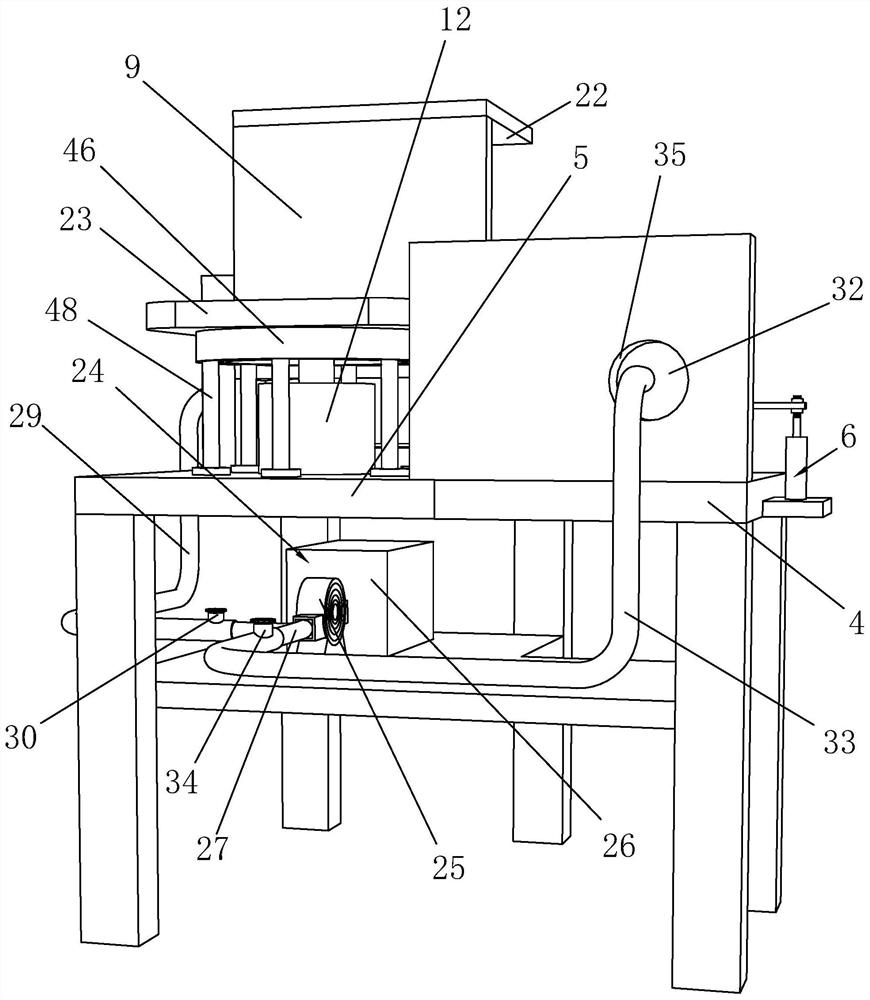

[0029] Such as Figure 1 to Figure 7 As shown, it is a drilling device for stainless steel plates of integrated stoves according to the present invention, which includes a workbench 1 and a drilling assembly 2. The workbench 1 includes a first workbench 3, a second workbench 4 and a placement platform 5. A workbench 3 and a second workbench 4 are vertically arranged on both sides of the placement platform 5, and the first workbench 3 and the second workbench 4 are provided with a clamping assembly 6, which includes a mounting plate 36, Clamping cylinder 37 and clamping block 38, clamping cylinder 37 is fixed on the mounting plate 36, the end of piston rod 49 of clamping cylinder 37 is provided with threaded section 39, clamping block 38 is connected with piston rod 49 through adjusting rod 40 , the adjusting rod 40 is located on the threaded section 39, the adjusting rod 40 includes a fixed rod 42 and a sliding rod 43, the sliding rod 43 is clipped in the adjusting chute of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com