An annular magnet based on a ReBCO superconducting ring

A superconducting ring and toroidal technology, applied in superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problem of large heat leakage of magnets, and achieve high current carrying capacity of magnets, low heat leakage, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

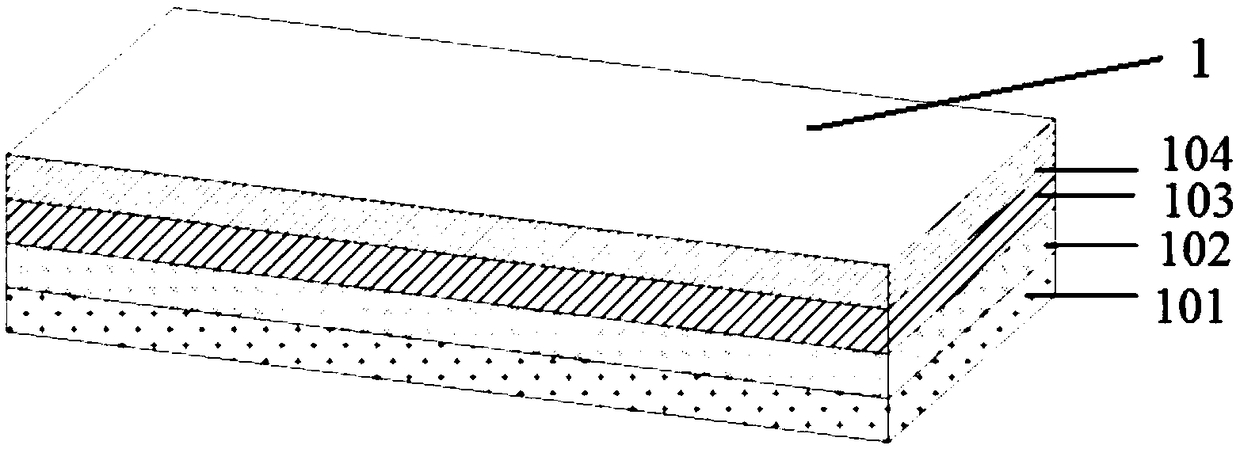

[0025] Prepare as attached figure 1 The specific process of the ReBCO superconducting sheet shown is as follows:

[0026] (1) Using the same substrate material as the second-generation high-temperature superconducting coating to produce a sheet-shaped substrate 101, wherein the substrate material is Ni, NiW, Hastelloy or stainless steel;

[0027] (2) On the substrate 101, a second-generation high-temperature superconducting buffer layer preparation process is used to deposit a buffer layer 102, wherein the buffer layer is an insulating metal oxide;

[0028] (3) On the buffer layer 102, a ReBCO thin film 103 is plated on the second generation high temperature superconducting thin film coating technology;

[0029] (4) Plating a protective layer 104 on the ReBCO thin film 103 , wherein the protective layer 104 is a silver thin film protective layer or a copper thin film protective layer, that is, the ReBCO superconducting thin sheet 1 is obtained.

[0030] The preparation proce...

Embodiment 2

[0032] prepared as figure 2 The specific process of the shown ReBCO superconducting ring is as follows:

[0033] in, figure 2 The specific preparation process of the first ReBCO superconducting ring piece 2 with a positioning hole cut at one corner of the D-shaped inner ring shown in -a is as follows:

[0034] A D-shaped ring sheet is cut on the ReBCO superconducting sheet obtained in Example 1, and the radius of the inner ring is r 1 , the outer ring radius is r 2 , the ring width is w 1 ;Cut out a radius r at the junction of the straight line and the arc of the D-shaped inner ring, that is, at the corner of the inner ring 3 The circular positioning hole 201, that is, as figure 2 The first ReBCO superconducting ring piece 2 shown in -a.

[0035] in, figure 2 The specific preparation process of the second ReBCO superconducting ring piece 3 with positioning holes cut at the two corners of the D-shaped inner ring shown in -b is as follows:

[0036] A D-shaped ring sh...

Embodiment 3

[0038] prepared as image 3 Insulation sheet shown: cut an organic insulation film such as PPLP insulation film, kraft paper or epoxy sheet into a D-shaped insulation sheet with the same shape and size as the ReBCO superconducting ring sheet shown in Example 2.

[0039] in, image 3 -a is with figure 2 - the first insulating sheet 4 with the same shape and size as the first ReBCO superconducting ring sheet 2 shown in a; image 3 -b for the same figure 2 - the second insulating sheet 5 with the same shape and size as the second ReBCO superconducting ring sheet 3 shown in b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com