A moisture analysis method in segmented drying

An analysis method and segmented technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of no segmented dry moisture analysis method, improve product quality and production energy efficiency, and benefit The effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A moisture analysis method in segmented drying may comprise the following steps:

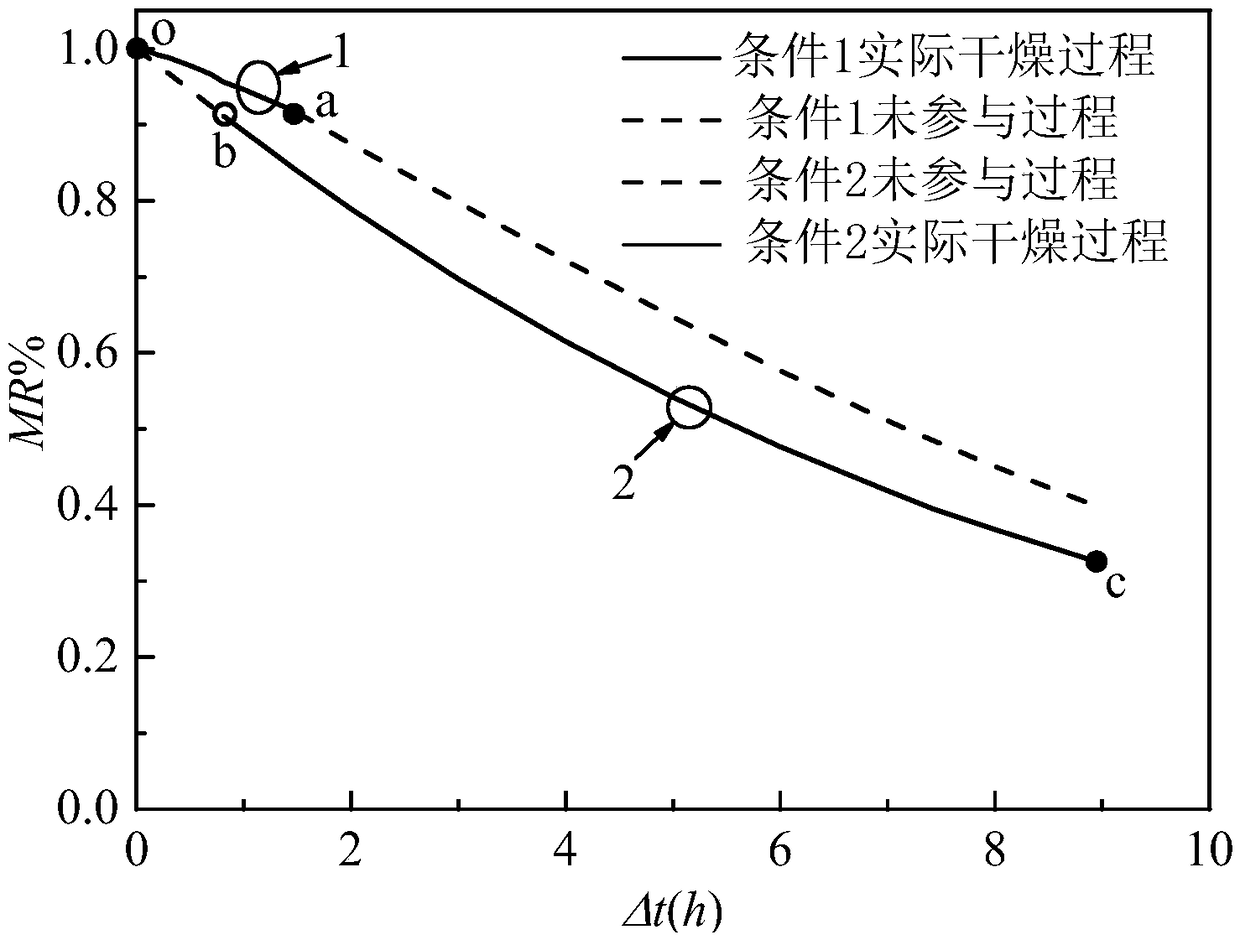

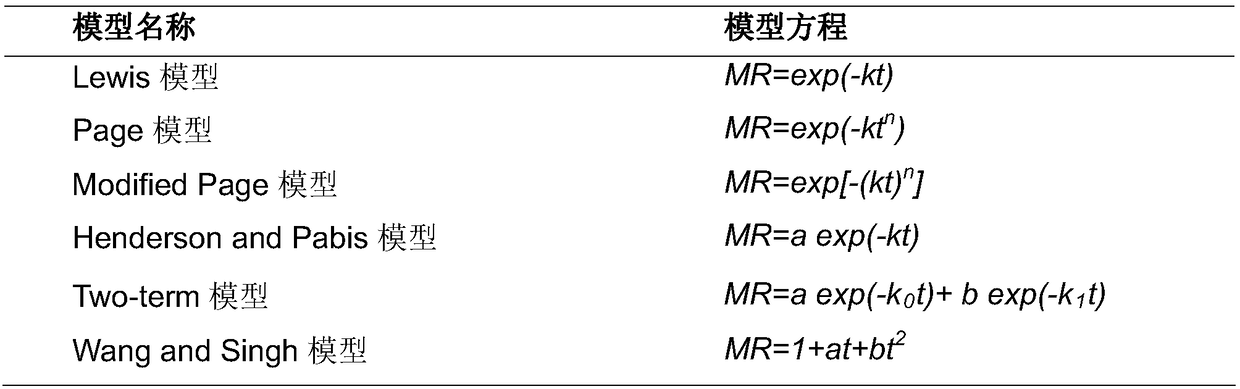

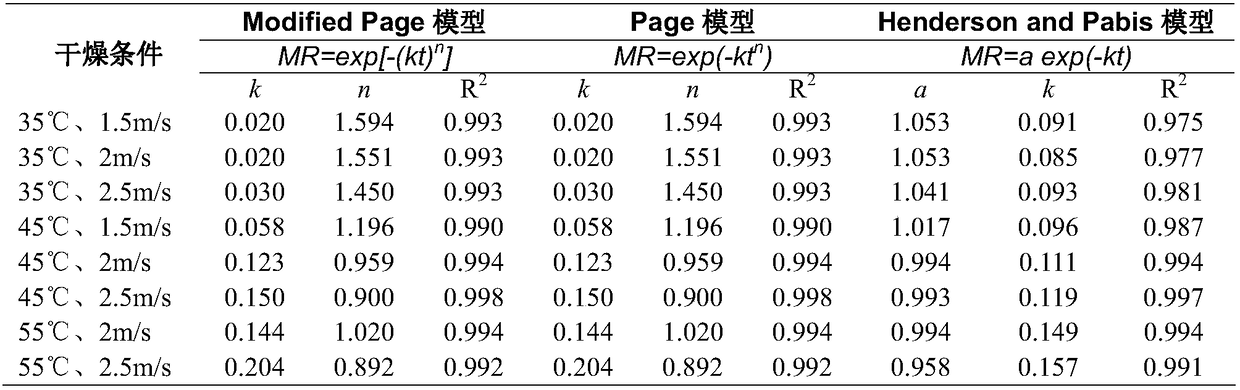

[0042] Step A1, using American ginseng as the material to be dried, and according to the data of eight groups of American ginseng constant temperature and constant speed drying experiments in "Research on Rapid Drying Technology of American Ginseng" (from the 2006 master's thesis of "Jilin University", author Ji Qingxiao), this The drying time under eight groups of drying conditions and the material moisture ratio at the end of each drying time were compared with the six semi-empirical drying dynamics of Henderson and Pabis model, Lewis model, Page model, Two-terms model, Modified Page model, and Wang and Singh model. The fitting calculation of the scientific model is carried out, and the fitting results are shown in Table 2 and Table 3 below:

[0043] Table 2

[0044]

[0045] table 3

[0046]

[0047] Note: In Table 2 and Table 3, MR means moisture ratio, t means drying time, R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com