Sampling device for obtaining cemented filling slurry on different layers and working method thereof

A technology of cement filling and sampling device, which is applied in sampling device, sampling, measuring device and other directions, to achieve the effect of wide application range, simple operation and realization of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

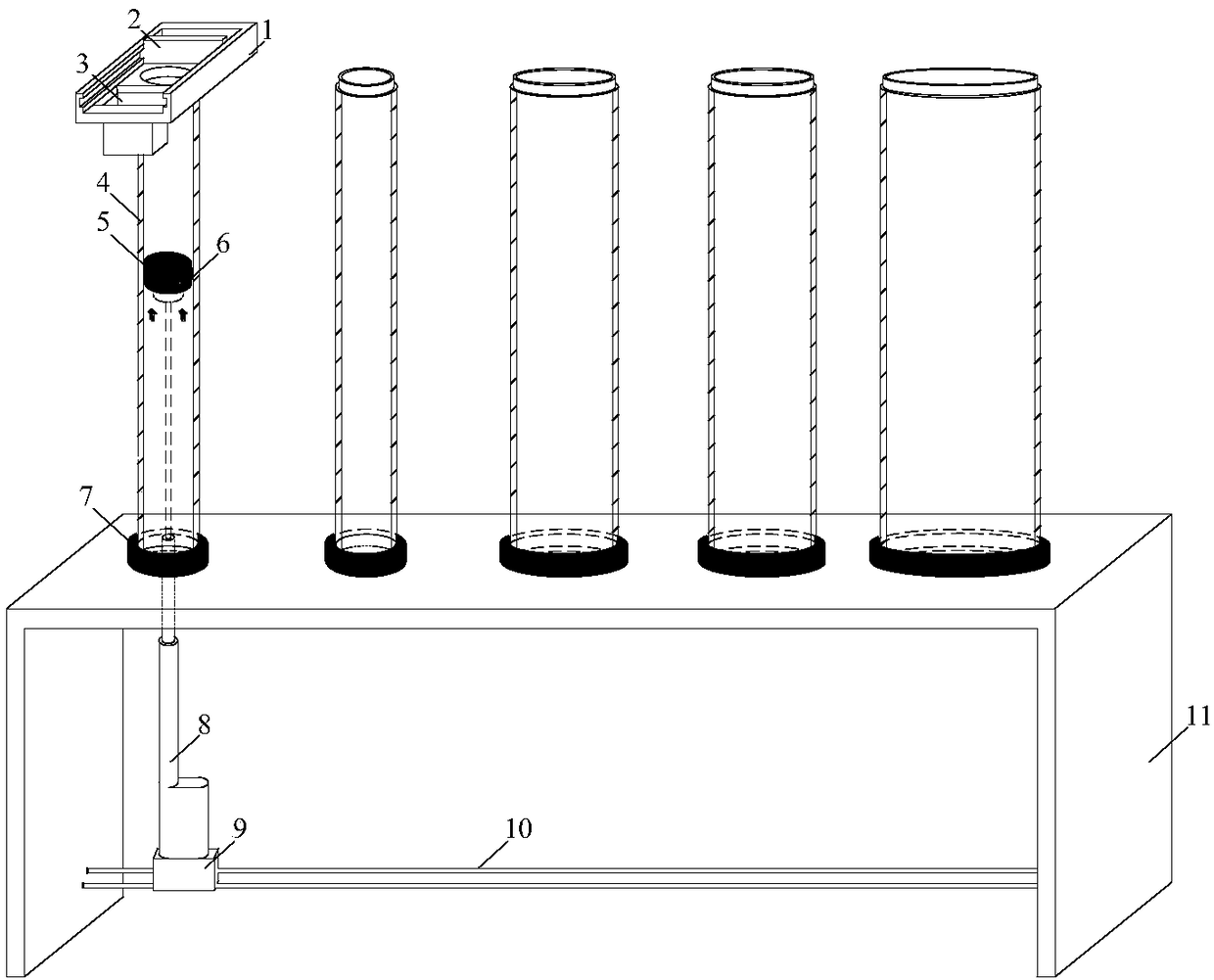

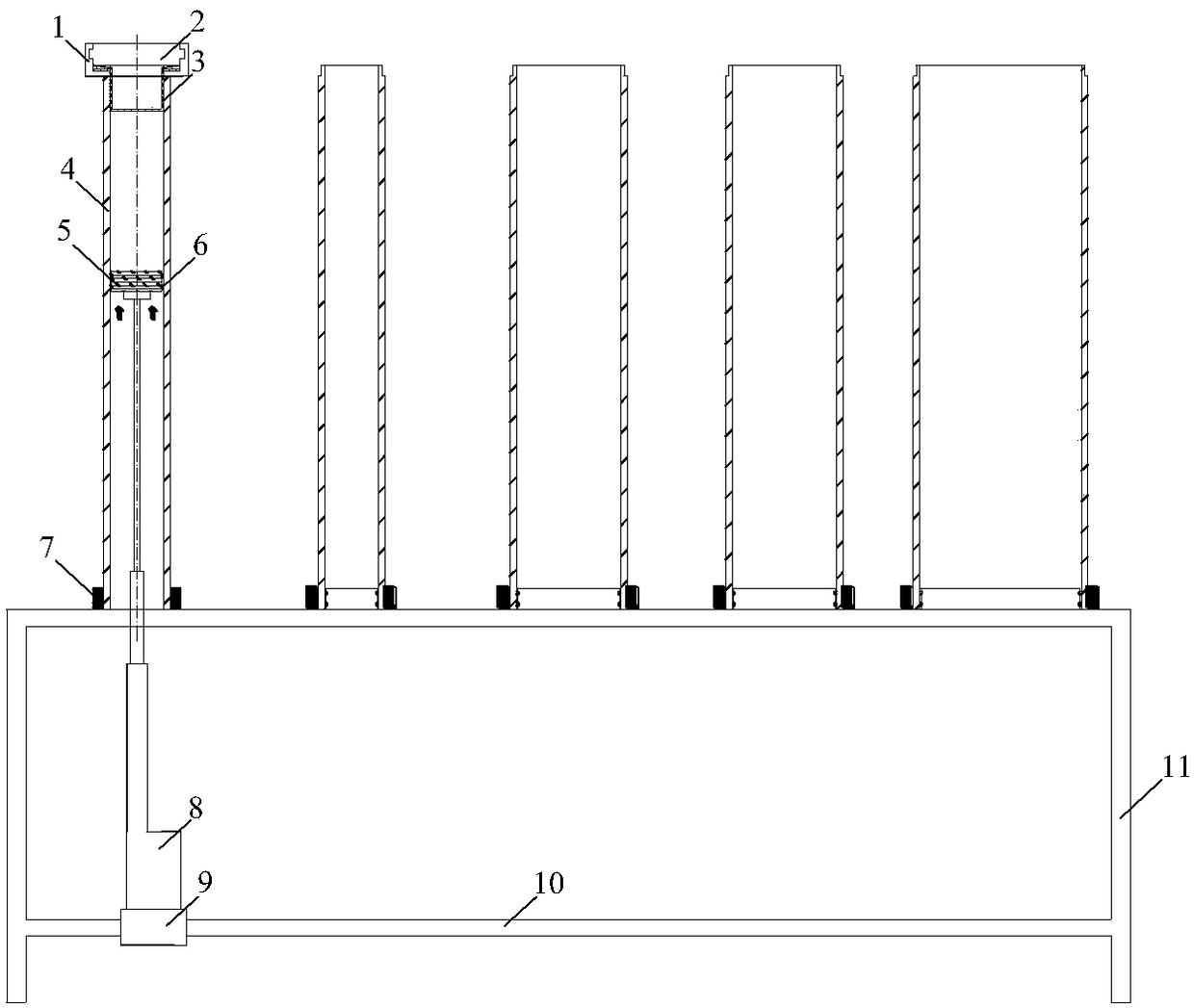

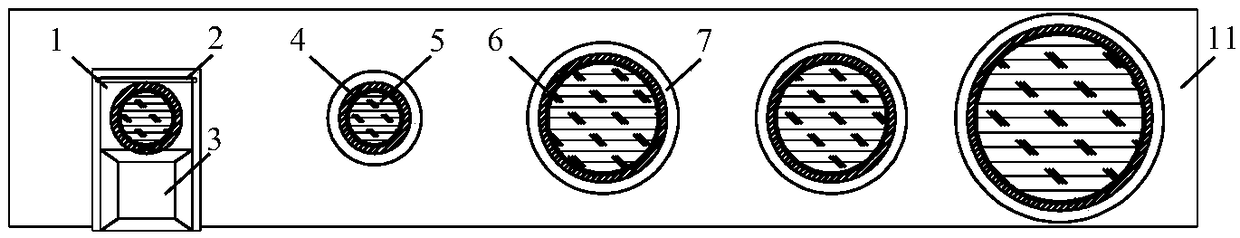

[0040] For the cemented filling slurry with a mass concentration of 70%, the slurry is made by mixing tailings, cement and water, and the concentration of its different layers changes with time. Take 800mL of slurry and place it in the discharge cylinder 4 with a diameter of 50mm. After standing still for one hour, move the electric telescopic rod 8 to correspond to the guide hole 12 and fix it, so that the electric telescopic rod 8 moves up and pushes the piston 5 to move. Thereby, the slurry in the discharge cylinder 4 is pushed into the transfer platform 1 through the round hole, and the push plate 2 on the transfer platform 1 is used to push the slurry through the square hole into the square container 3, and then the sample with the slurry is taken out. Square container 3, install a new square container 3 again, the remaining slurry is divided repeatedly according to above-mentioned steps successively, wait to take out all slurry, measure the concentration of slurry in diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner wall diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com