Transmission structure of water pump and engine

A transmission structure and engine technology, applied in the field of mechanical transmission, can solve the problems of skipping shafts, inconvenient installation and maintenance, etc., and achieve the effects of high installation accuracy, stable installation, and convenient and fast installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

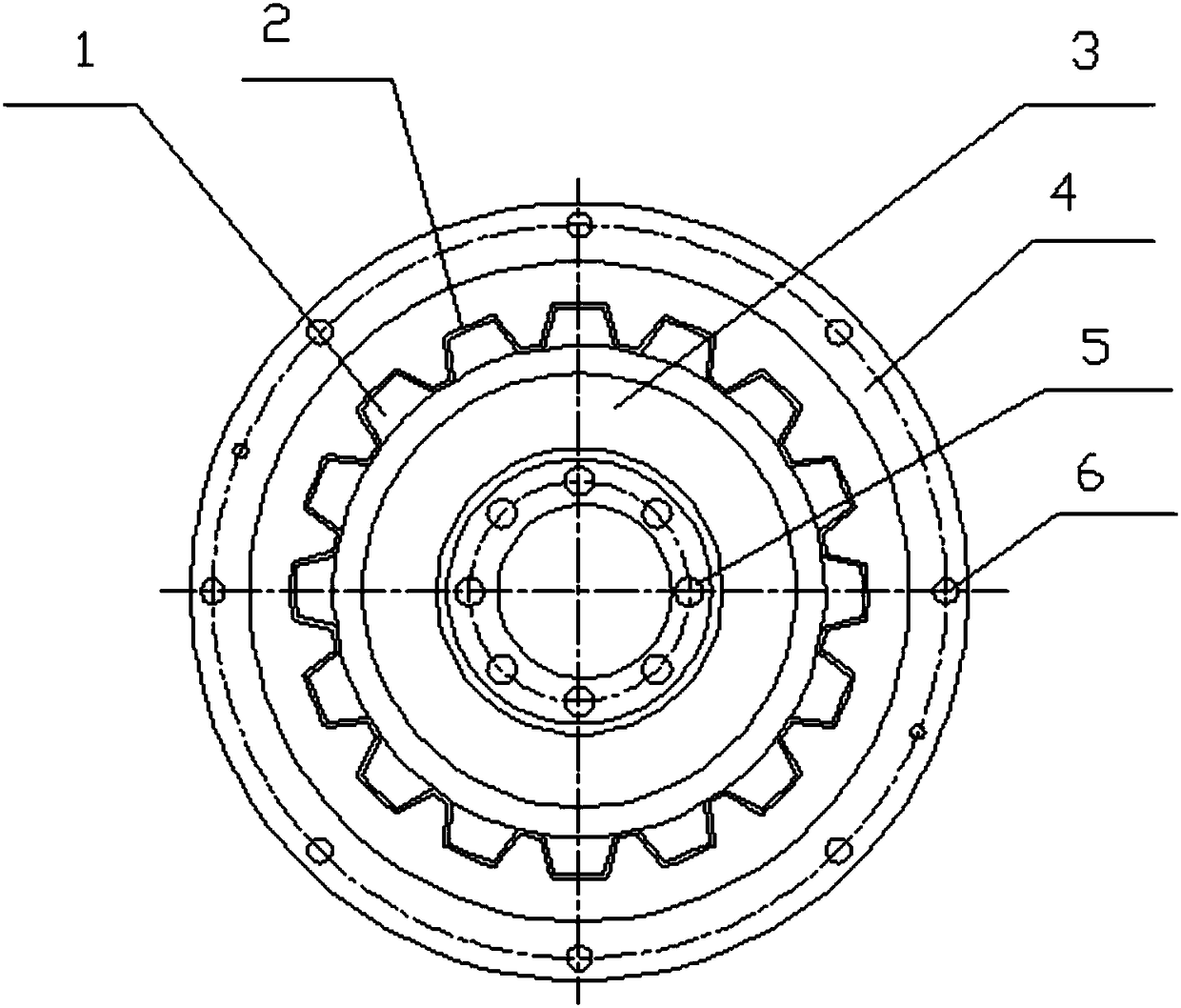

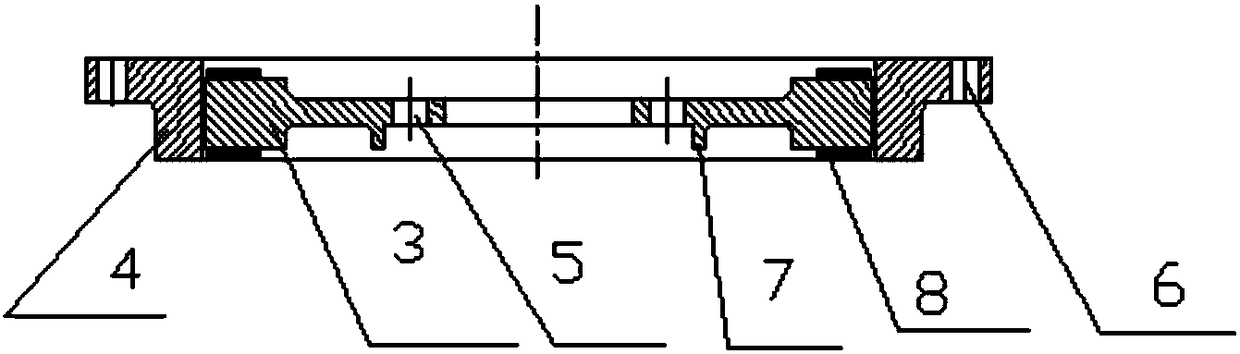

[0014] As shown in the figure, there is a transmission structure for a water pump and an engine. The transmission structure is a toothed connecting plate, and the toothed connecting plate includes an inner plate 3 and an outer plate 4. The outer plate is sleeved outside the inner plate, and the upper edge of the outer plate is A plurality of engine connection through holes 6 are evenly distributed in the circumferential direction, the inner wall of the outer disk is provided with inner teeth 2, the outer wall of the inner disk is provided with outer teeth 1, and the outer teeth and the inner teeth are meshed with each other. A plurality of shaft coupling installation through holes 5 are evenly arranged along the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com