Quasi-zero stiffness positive stiffness adjusting method, quasi-zero stiffness adjusting method and vibration isolator

A technology of quasi-zero stiffness and adjustment method, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of performance sensitivity to bearing mass, discount of vibration isolation system effect, non-quasi-zero state, etc., achieve good low-frequency vibration isolation effect, and benefit Engineering application, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

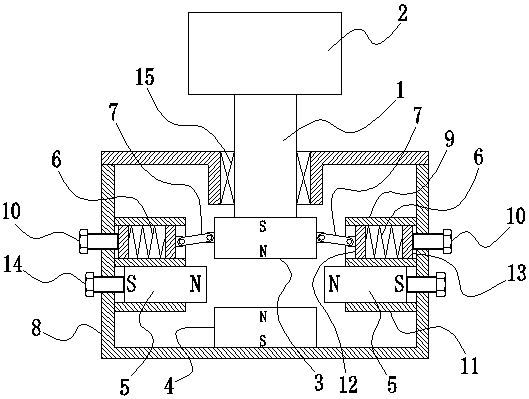

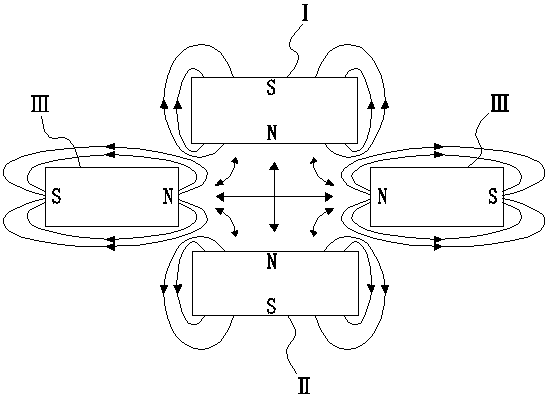

[0036] Example: such as figure 1 As shown, a quasi-zero stiffness positive stiffness adjustment method, which is to set a support column 1 that can move up and down in the quasi-zero vibration isolator, and is connected to the top of the support column 1 by the vibration isolator 2, along the support column 1 Magnet 1 3 and Magnet 2 4 are arranged in sequence in the axial direction, Magnet 1 3 is arranged on the bottom of the support column 1, Magnet 2 4 is arranged on the quasi-zero vibration isolator, Magnet 1 3 and Magnet 2 4 are opposite to each other to form a magnetic force The spring provides vertical positive stiffness for the quasi-zero vibration isolator, and two or more than two Magnet three 5, the same-sex magnetic poles between two or more magnets three 5 are arranged oppositely and the same-sex magnetic poles arranged between the two or more magnets three and the same-sex magnetic poles arranged between magnet one and magnet two Belong to the same polarity, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com