Ventilation and dust removal system for underground large-section and long-distance heading face

A technology of dust removal system and large section, applied in the field of long-distance excavation face ventilation and dust removal, large section of mine, ventilation and dust removal system field, can solve the problems of polluted underground air flow, dust with poor ventilation effect, etc., to achieve reliable operation and improve air flow Effective use of efficiency and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better describe the present invention, a ventilation and dust removal system for underground large-section and long-distance driving faces will be further described in detail in conjunction with the accompanying drawings.

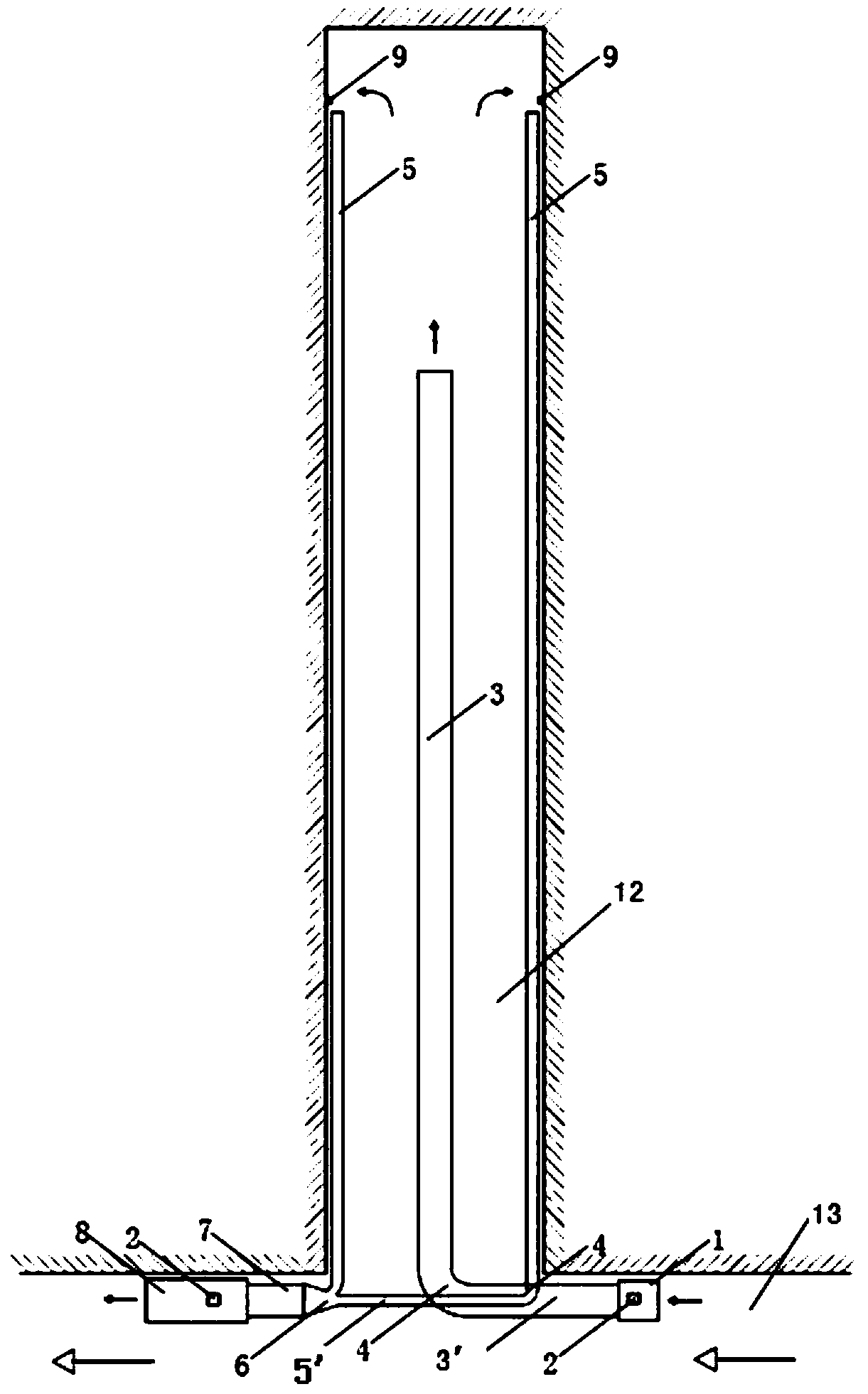

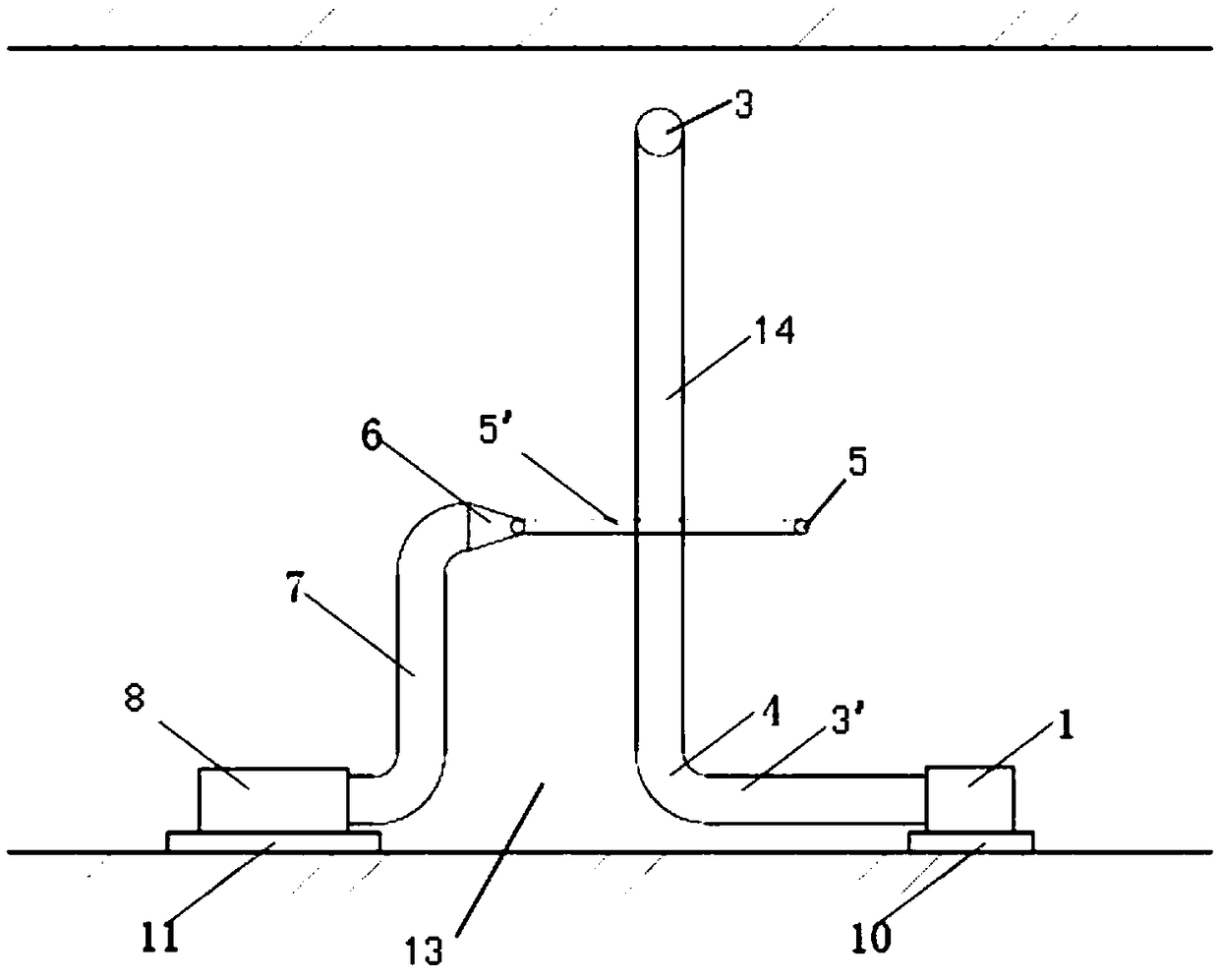

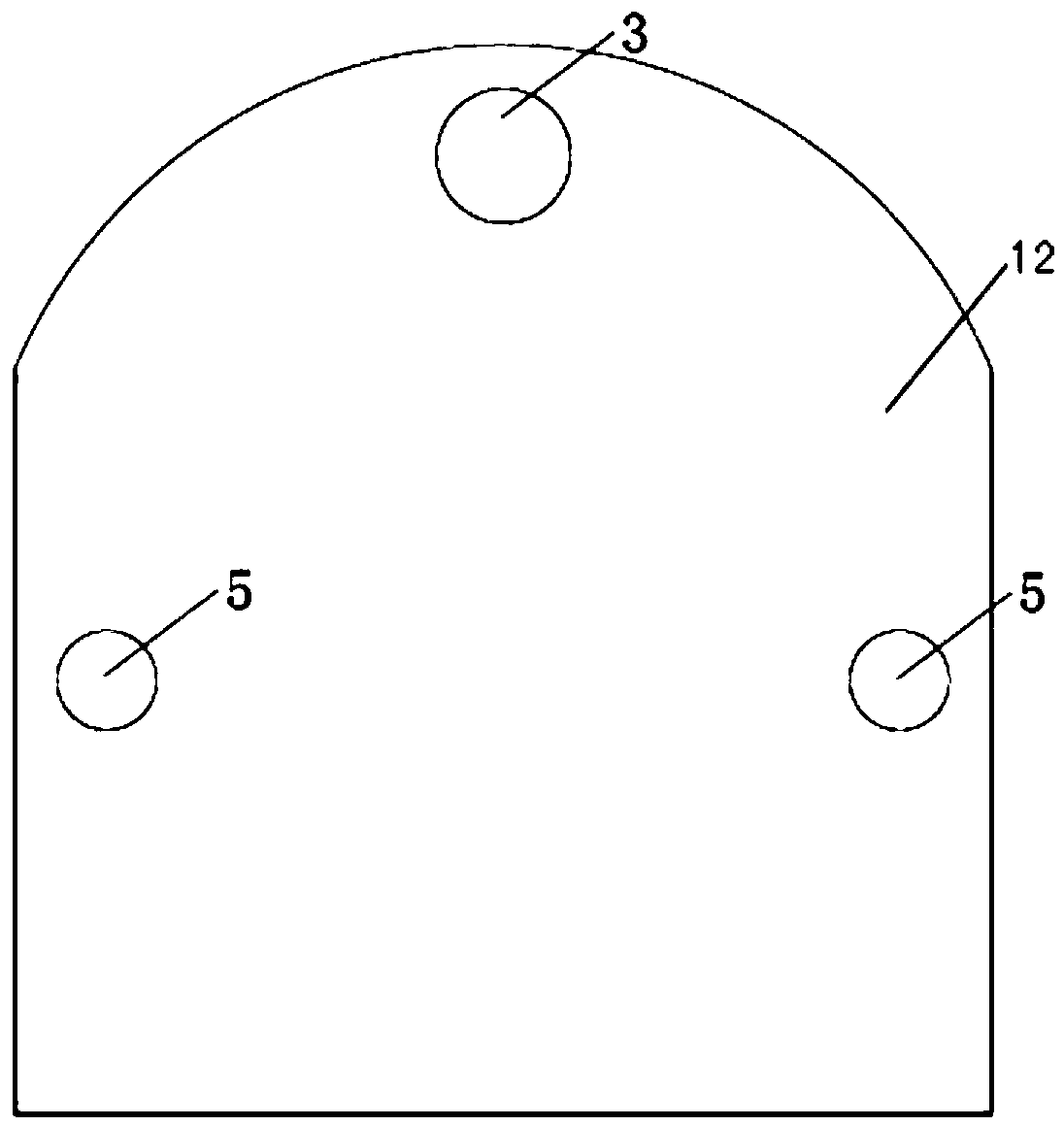

[0020] Depend on figure 1 Shown is a schematic diagram of the plane layout of a ventilation and dust removal system for underground large-section and long-distance driving faces and combined with figure 2 , image 3 It can be seen that a ventilation and dust removal system for underground large sections and long-distance excavation faces of the present invention includes a blower fan 1 arranged on the windward side of the middle road 13, a pressure air cylinder 3 and an exhaust air cylinder 5 arranged along the excavation roadway 12, The sectional area of each air exhaust tube 5 is half of the sectional area of the compressed air tube 3; the described compressed air tube 3 is hung horizontally on the centerline position at the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com