GAT (GuAnTe) Exterior formwork cast-in-place concrete composite insulation system and construction technique thereof

A technology of composite thermal insulation and external formwork, which is applied in the fields of formwork/formwork/work frame, thermal insulation, and on-site preparation of building components. It can solve the problems of cumbersome construction process, energy consumption, and easy to fall off, and achieve freeze-thaw resistance Strong performance in wind resistance and wind load, good waterproof permeability and air permeability, and the effect of improving construction quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

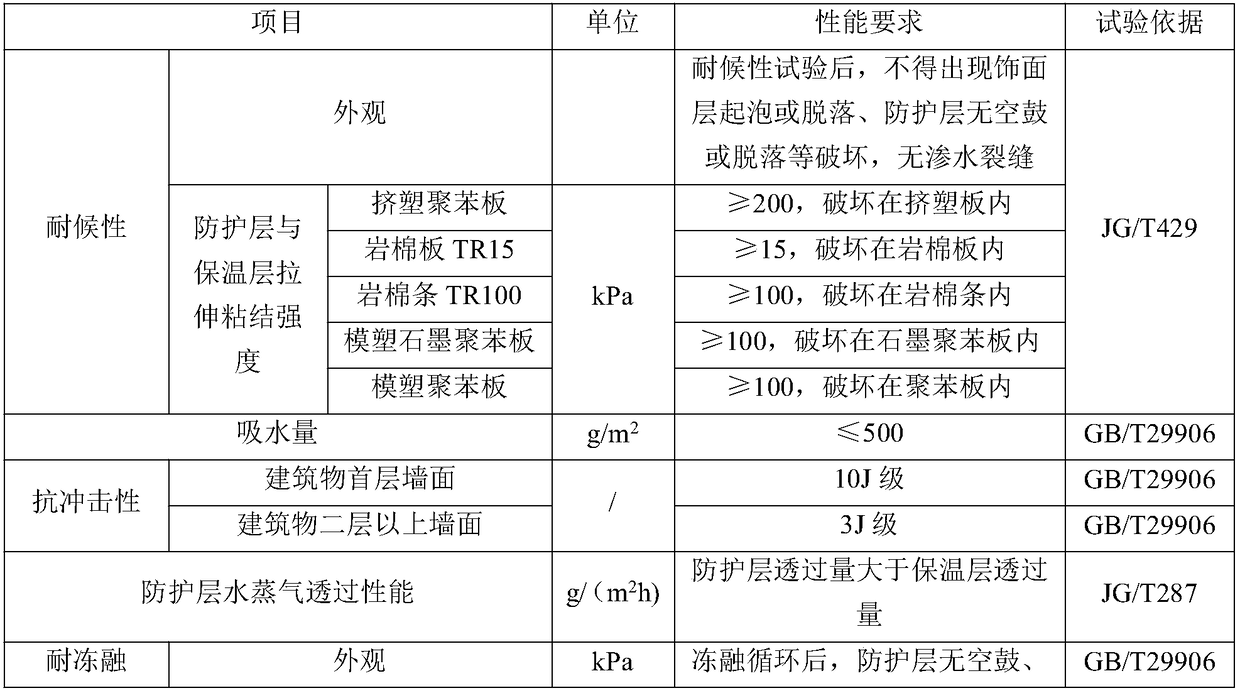

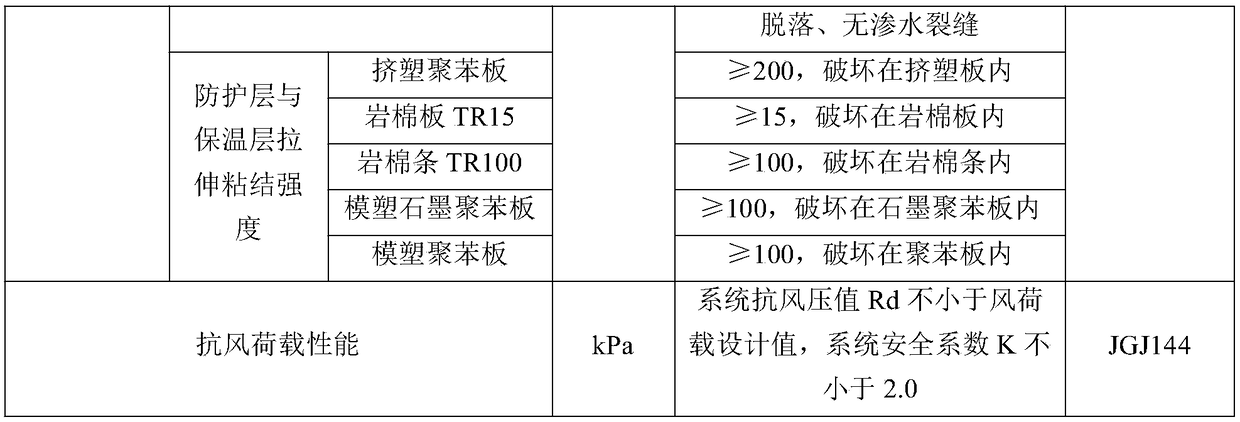

[0037] Such as figure 1 As shown, a GAT external formwork cast-in-situ concrete composite thermal insulation system of the present invention includes a GAT composite thermal insulation external formwork 1 and an internal formwork 2, and the GAT composite thermal insulation external formwork 1 is a formwork that does not need to be dismantled, and the GAT composite thermal insulation external formwork 1 and Concrete is poured between the inner formwork 2 to form a cast-in-place concrete wall 3, and the GAT composite thermal insulation outer formwork 1 and the cast-in-place concrete wall 3 are connected and fixed through the anchor bolt 4, and the outer side of the GAT composite thermal insulation outer formwork 1 is provided with a leveling protective layer 5. The outer side of the leveling protection layer 5 is provided with a facing layer 6; the GAT composite thermal insulation outer formwork 1 includes an inner adhesive surface layer 11, an insulating core material 12, an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com