Apparatus for preparing adipose tissue and method for preparing adipose tissue using the apparatus

An adipose tissue and fat technology, applied in biochemical equipment and methods, tissue culture, cell dissociation methods, etc., can solve the problems of increasing pollution, increasing the difficulty of operation, increasing pollution, etc., to reduce the number of manual operations, simplify the The effect of preparing the operation process and reducing the complexity of the machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

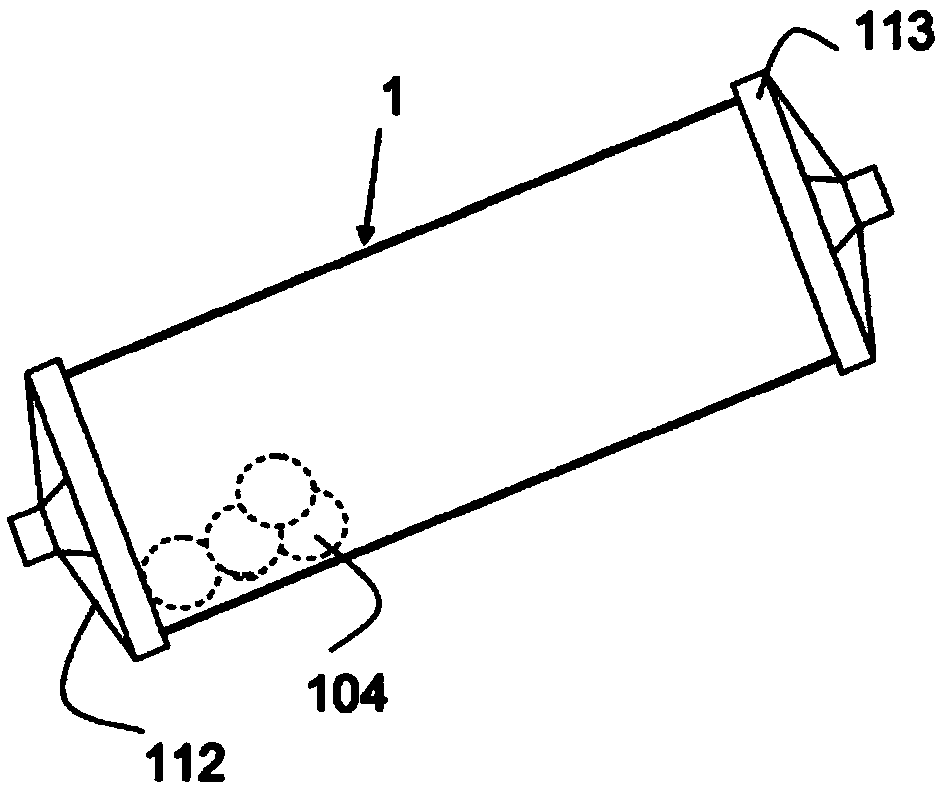

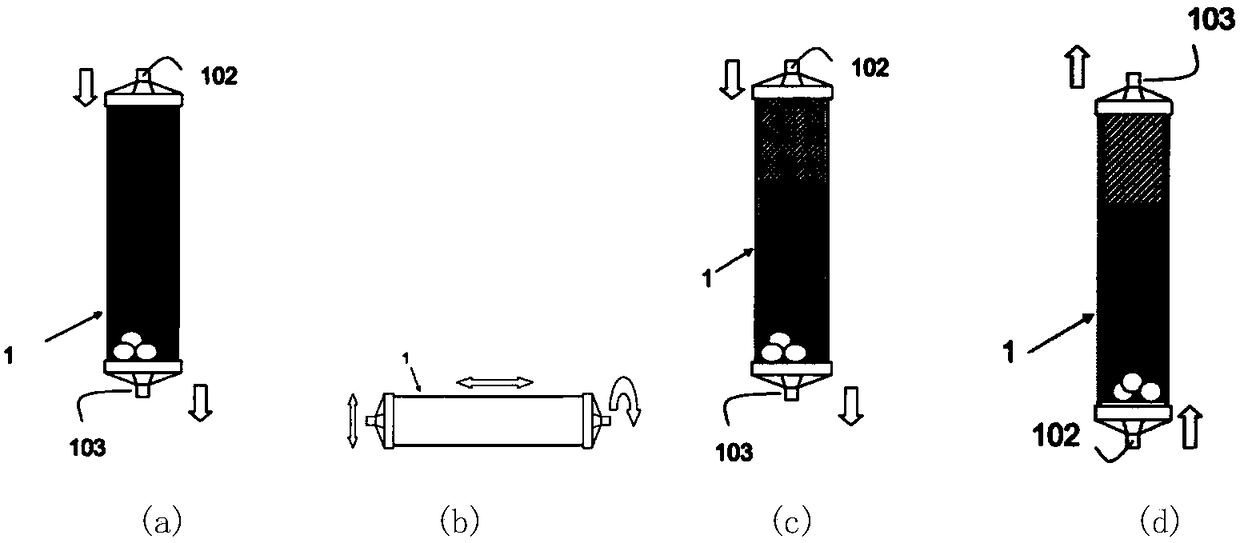

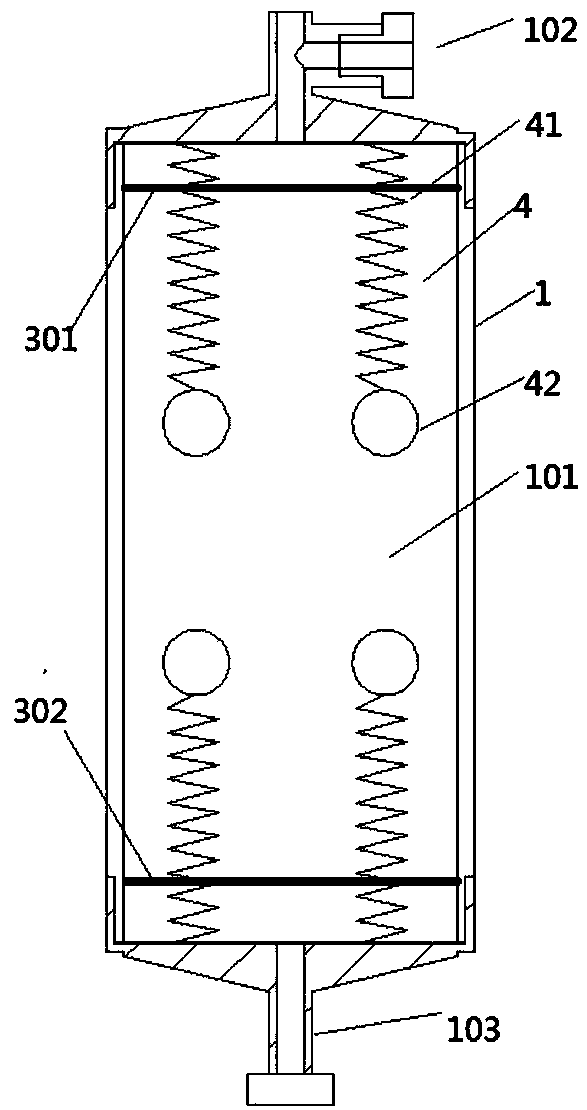

[0036] image 3 A schematic longitudinal section through a washing and separating container according to a first embodiment of the invention is shown. The washing and separating container 1 has a washing chamber 101 for washing the aspirated material, said container 1 has an inlet 102 and an outlet 103 through which the suctioned fatty material enters the washing chamber 101 and according to The chronological sequence, i.e. the sequence of first the fluid components and then the solid components, leaves the chamber 101 through the outlet 103, and the washing chamber 101 comprises Emulsions of oil, blood and / or other sterile liquid solutions.

[0037] The emulsion forming device is composed of at least one stirring assembly 4, and the at least one stirring assembly 4 includes an elastic member 41 and a ball 42 fixedly connected to the elastic member 41. Specifically, the elastic member 41 may be a coil spring. Optionally, elastic members 41 are fixedly attached to the top and...

no. 2 approach

[0045] A washing and separating vessel according to a second embodiment of the present invention such as Figure 4 As shown, its structure is similar to that of the first embodiment, except that an elastic member 41 in the form of a coil spring is fixed to the side wall of the washing and separating container 1 .

[0046] Optionally, the stirring components are alternately arranged on opposite sides of the inner wall of the washing and separating container 1 .

[0047] Optionally, the stirring assembly is arranged on the side wall of the washing and separating container 1 in a spiral form.

[0048] In this embodiment, optionally, between the first size reducing net 301 and the second size reducing net 302, at a position closer to the inlet 102 than the outlet 103, a third size reducing net 303 is provided .

[0049] The material to be treated passes through two stages of size reducing nets 301, 303 before entering the washing chamber 101 of the washing and separation vessel ...

no. 3 approach

[0051] According to the washing and separating container of the third embodiment of the present invention such as Figure 5 As shown, its structure is similar to that of the first embodiment (the size reduction net is omitted and not shown), except that the elastic member 41 in the form of a coil spring is not connected to the washing and separating container 1, but has a free end. In this embodiment, the elastic member 41 provides sufficient rebound force against the inner wall of the container 1, so that whether the container 1 is in a vertical orientation or a horizontal orientation, the shaking of the container 1 can cause active movement of the ball 42 , so as to effectively improve the emulsification effect.

[0052] Optionally, balls 42 are provided at both ends of the elastic member 41 in the form of a coil spring.

[0053] In this embodiment, optionally, 1-3 additional size-reducing nets are added at any position between the first size-reducing net 301 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com