Main beam structure of electric single-beam bridge crane

A bridge crane and beam structure technology, which is applied in the direction of supporting structure, load hanging components, transportation and packaging, etc., can solve the problems of the main beam structure such as self-heaviness, achieve low operating cost, increase effective working space, structural safety and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

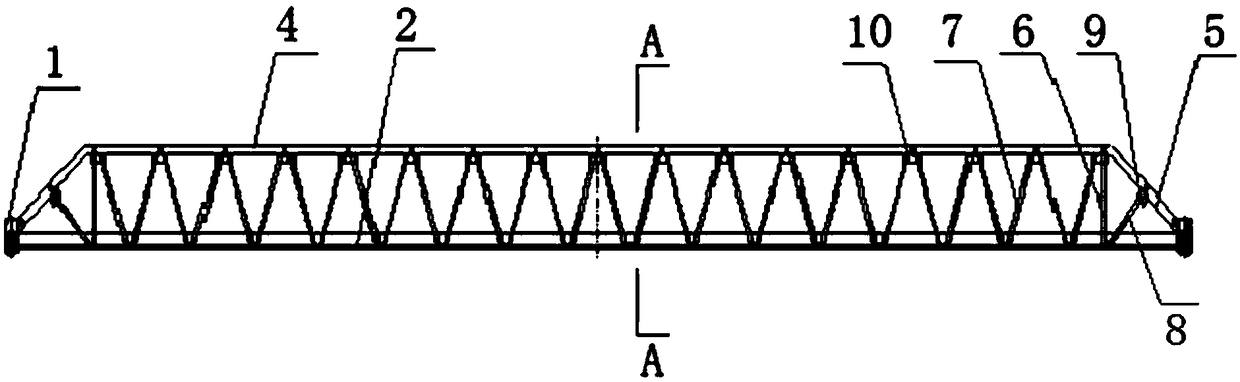

[0019] Such as Figure 1 ~ Figure 2 As shown, the present invention provides a main girder structure of an electric single girder bridge crane. The cross section of the main girder is approximately "inverted trapezoid", which can improve the safety and stability of the entire main girder during lifting and moving operation. , including a symmetrically arranged end beam walking mechanism 1, and also includes a horizontally parallel bottom plate 2 and a top plate 3, the two ends of the top plate 3 are fixedly connected with symmetrical fixed rods 4, and the two ends of the bottom plate 2 respectively travel with the two end beams The mechanism 1 is fixedly connected, the two ends of the fixed rod 4 are fixedly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com