Gantry crane

A gantry crane and gantry technology, which is applied in the direction of hoisting equipment braking devices, load hanging components, bottom support structures, etc., can solve the problems of large overall wheel pressure of the crane, waste of production raw materials, and large consumption of raw materials, etc., to achieve convenience The effect of moving and installing, wheel pressure lower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

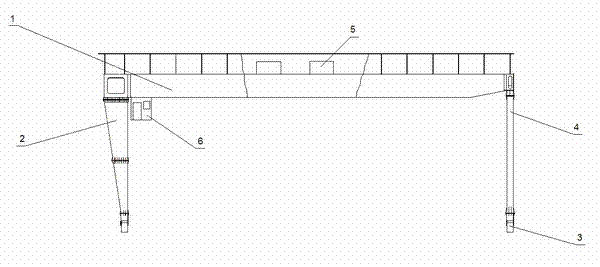

[0010] figure 1 Shown is a schematic diagram of the structure of a gantry crane. A gantry crane includes a mast 1 , a left door leg support 2 , a cart 3 , a right door leg support 4 , a trolley 5 and a driver's cab 6 . The side profile of the left door leg support 2 is an inverted trapezoid.

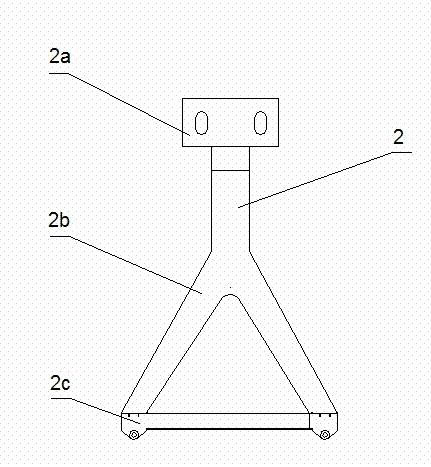

[0011] figure 2 Shown is a schematic diagram of the structure of the left door leg bracket in the gantry crane. The left door leg bracket 2 is a human-shaped structure, and is composed of a rigid leg upper crossbeam 2a, a rigid leg 2b and a rigid leg lower crossbeam 2c.

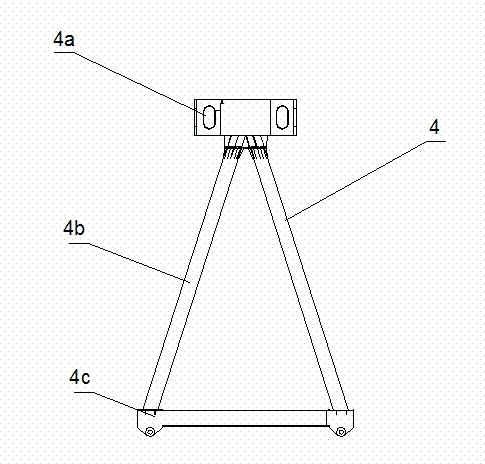

[0012] image 3 Shown is a schematic diagram of the structure of the right door leg bracket in the gantry crane. The right door leg support 4 adopts a triangular structure, and is composed of an upper crossbeam 4a, a leg 4b and a lower crossbeam 4c. In order to further reduce the wheel pressure, the right door leg support 4 adopts a hollow structure.

[0013] The door leg support structure described in the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com