Dust collecting device used for packaging mortar in bulk and bulk mortar packaging device

A technology of dust collection device and mortar, applied in the direction of loading/unloading, transportation and packaging, conveyors, etc., to achieve the effect of improving dust removal effect, avoiding blockage, and increasing patency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

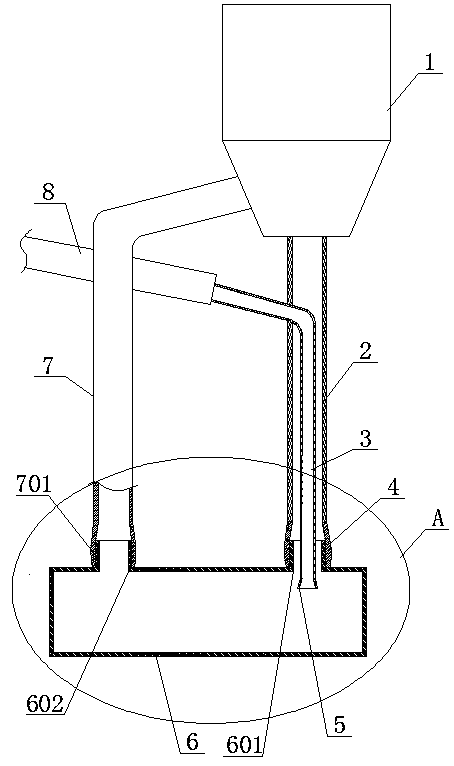

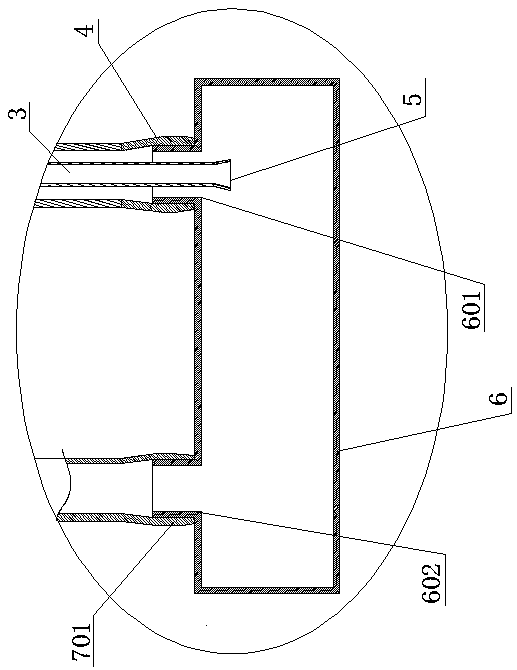

[0037] as attached figure 1 And attached figure 2 Shown, the present invention is used for the dust collecting device of mortar bulk, comprises air inlet duct 2, dust remover 1 and dust collection pipe 7, and this dust remover 1 is bag filter, and the first port of air inlet pipe 2 and dust removal The second port of the air intake pipe 2 is connected to the rear filling port 601 of the mortar tanker, and the dust collector 1 and the rear filling port 601 of the mortar tanker are connected through the air intake pipe 2; the dust suction pipe is a telescopic soft The longitudinal section of the inlet end 701 of the dust suction pipe is an inverted V shape, and the inlet end 701 of the dust suction pipe is a spiral hose, and the inlet end 701 of the dust suction pipe passes through the rubber flange and the front of the mortar tanker. The filling port 602 is sealed and connected, the outlet end of the dust suction pipe is connected to the dust collector 1, and the dust suction...

Embodiment 2

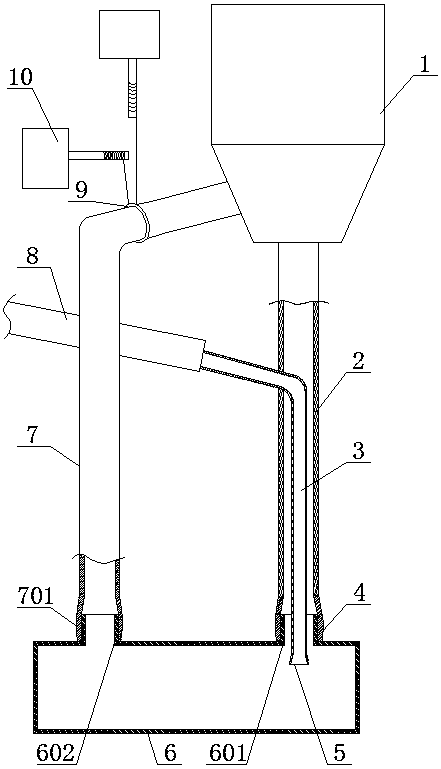

[0044] as attached figure 1 , attached figure 2 And attached image 3 As shown, the mortar bulk device of the present invention includes a mortar tank car 6, a mortar delivery tank 8 and a discharge pipeline 3, and also includes the dust collection device disclosed in Embodiment 1 for mortar bulk packaging, and the dust collection pipeline 7 is communicated with the dust collector 1 Between the front filling port 602 of the mortar tanker, the air intake pipe 2 is connected between the dust collector 1 and the rear filling port 601 of the mortar tanker. Above the tank car 6, the inlet of the blanking pipeline 3 communicates with the outlet of the mortar delivery tank 8, and the outlet of the blanking pipeline 3 passes through the feeding communication port and the rear filling port 601 of the mortar tank car and extends into the mortar tank car 6 in turn.

[0045] Specifically, the inlet end 701 of the dust suction pipe is sealed and communicated with the front filling port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com