Flexible pouch production line conveying system

A flexible packaging bag and conveying system technology, applied in packaging, conveyors, conveyor objects, etc., can solve problems such as affecting production and unfavorable production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

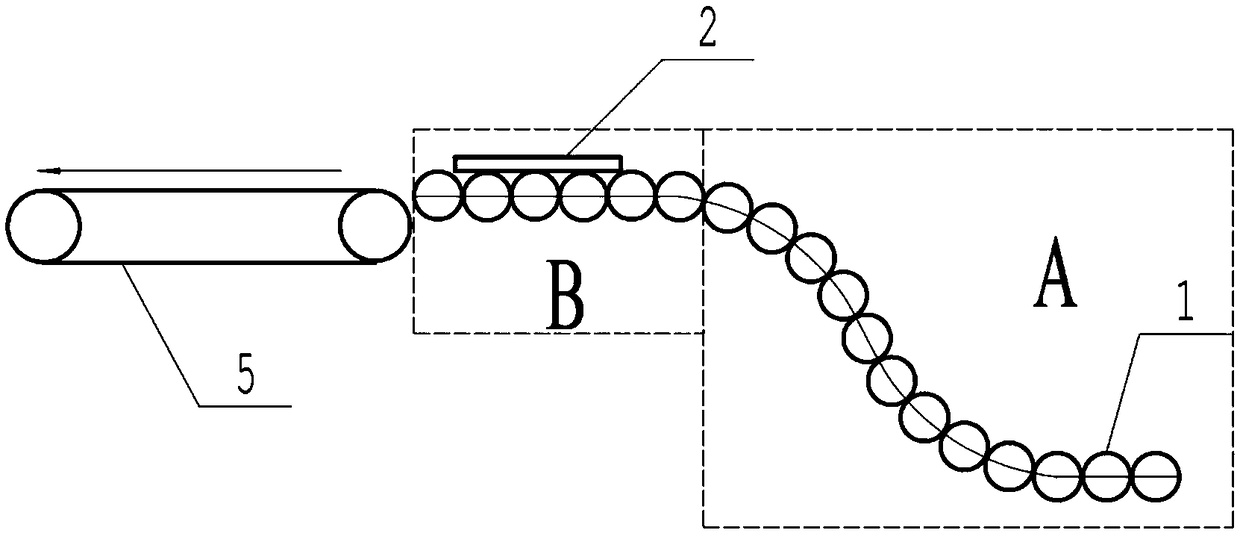

[0015] Such as figure 1 The conveying system of the flexible packaging bag production line shown includes a low-speed conveying stage, a high-speed conveying stage and a stepping conveying mechanism.

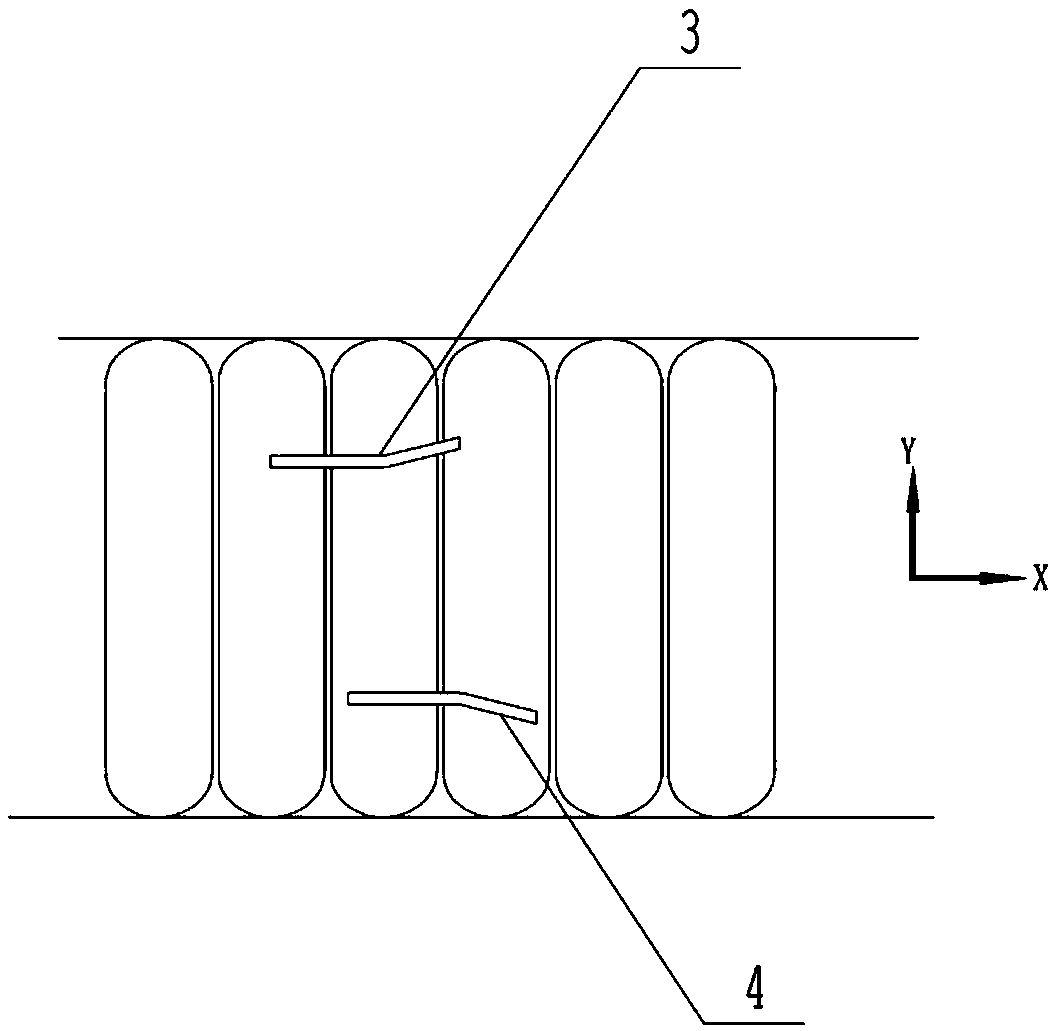

[0016] The low-speed conveying stage and the high-speed conveying stage are conveyed by several driving rollers. The low-speed conveying stage transitions to the high-speed conveying stage at a constant speed, and the low-speed conveying stage increases at a constant speed from beginning to end. During the transition from the low-speed conveying stage to the high-speed conveying stage, an upward slope is set to further control the stacking of flexible packaging bags. During the transition from the conveying stage to the high-speed conveying stage, the speed of the high-speed conveying stage is greater than that of the low-speed conveying stage, so that the stacked flexible packaging bags can be separated and staggered to ensure regular and orderly conveying of the flexible packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com