Iron-cast robot

A technology of robots and cast iron, applied in casting equipment, manufacturing tools, equipment for handling casting molds, etc., can solve the problems of low casting efficiency and threaten the safety of workers, and achieve the effect of improving casting efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

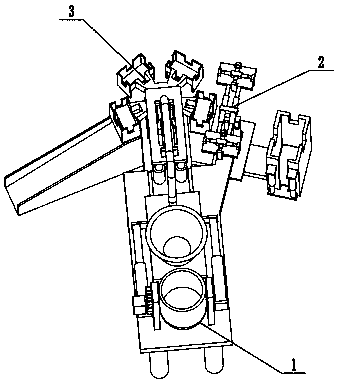

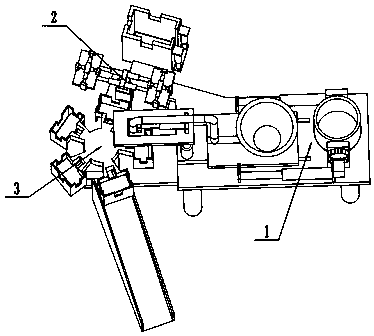

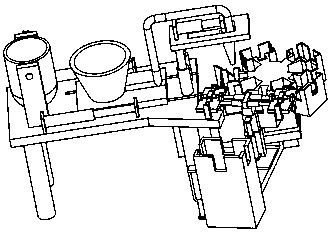

[0015] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, a cast iron casting robot includes a base 1, a mold handling part 2, and a turntable part 3, and is characterized in that the bottom of the fifth hydraulic cylinder 201 of the mold handling part 2 is fixedly installed on the side of the bottom plate 101 of the base 1 ; The regular pentagonal plate 303 of the turntable part 3 is fixedly installed on the motor shaft of the second stepping motor 117;

[0016] The base 1 includes a bottom plate 101, a support column 102, a support plate 103, a first stepper motor 104, a first gear 105, a second gear 106, a melting furnace 107, a first hydraulic cylinder 108, a backing plate 109, and a casting liquid Storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com