Nanoscale nickel phosphide/carbon cloth composite material and its preparation method and application in electrocatalyst

A composite material and nano-scale technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high toxicity of gas-solid reactions, unfavorable industrialization, difficult industrialization, etc., and achieve excellent The effect of hydrogen production rate, great application potential and industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] S1: Prepare a precursor solution with a nickel sulfate concentration of 0.05mol / L, a sodium hypophosphite concentration of 0.5mol / L, and a sodium citrate concentration of 0.1mol / L;

[0036] S2: Put the above precursor solution in a constant temperature glass reactor, the counter electrode is a platinum sheet electrode, the reference electrode is a silver silver chloride electrode, and the working electrode is a carbon cloth, and pulse deposition is selected on a CHI electrochemical workstation, specifically: :

[0037] S2-1: Under the voltage of -0.5V, deposit for 1s;

[0038] S2-2: Deposit at -2.2V voltage for 20s, and cycle 10 times to obtain nickel phosphide / carbon cloth under this condition;

[0039] S2-3: The obtained nickel phosphide / carbon cloth was washed with ethanol and distilled water, and dried in a vacuum oven at 60°C overnight to obtain a nanoscale nickel phosphide composite material, which was named H1.

Embodiment 2-5

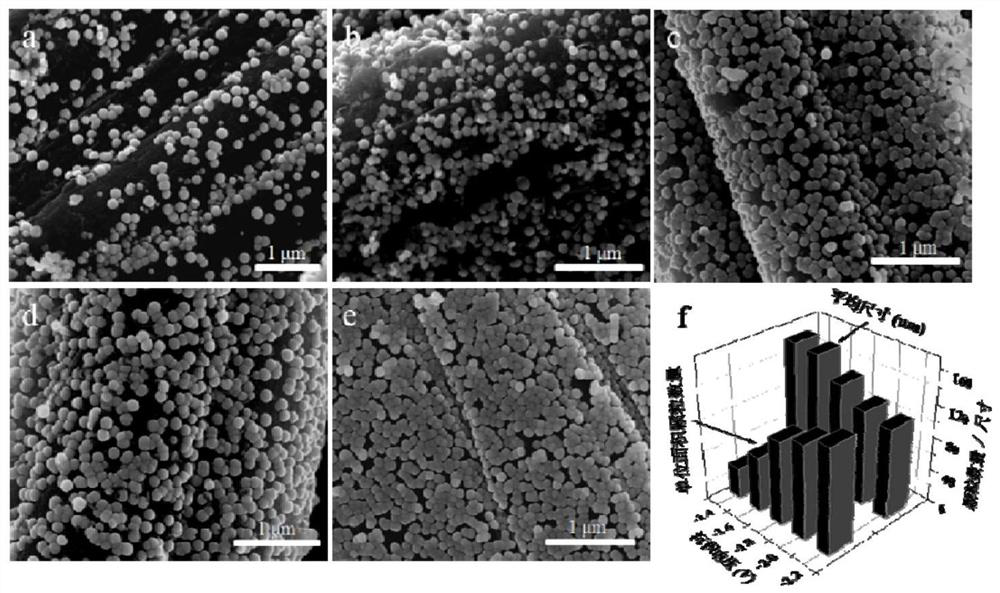

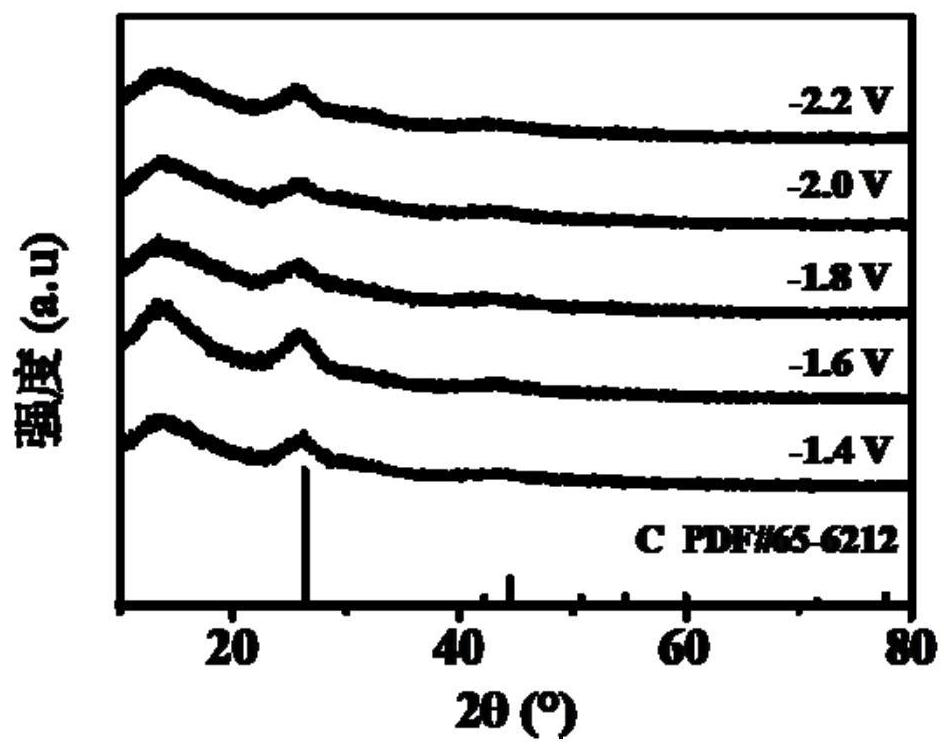

[0040] Embodiment 2-5: Investigation of different deposition voltages

[0041] Except that different deposition voltages shown in Table 1 below were used in step S1, other operations were the same as in Example 1, so that Embodiments 2-5 were carried out. The deposition time and composite material names used are shown in Table 1 below.

[0042] Table 1. Composite materials obtained under different deposition voltages

[0043]

Embodiment 6-7

[0044] Embodiment 6-7: the investigation of deposition time

[0045] Except that the different deposition times shown in Table 2 below were used in step S1, other operations were the same as in Example 1, so that Examples 6-7 were carried out. The deposition times and names of composite materials used are shown in Table 2 below.

[0046] Table 2. Composite materials obtained under different deposition times

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com