Device for testing cement hydration heat at constant temperature

A cement hydration and constant temperature technology, applied in the field of cement detection, can solve the problems of lack of constant temperature environment, unable to capture the temperature change curve, etc., achieve the effect of wide application range, high accuracy, and eliminate the error of hydration heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

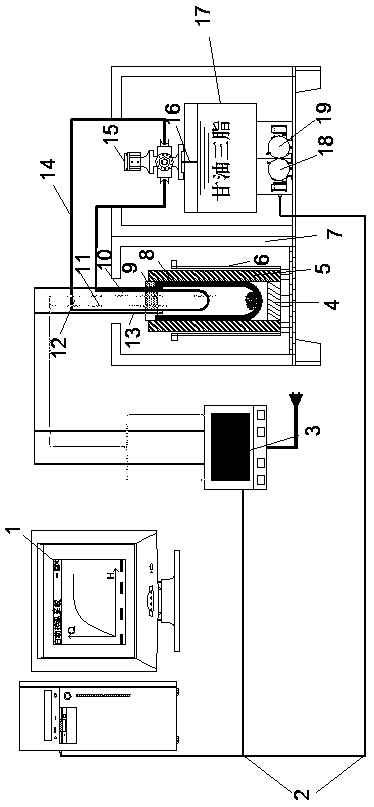

[0018] Such as figure 1 As shown, a device for testing the heat of hydration of cement at a constant temperature includes a computer with an automatic temperature control system 1, a temperature recorder 3, two metal boxes 7, and a triglyceride box 17.

[0019] A metal box 7 is provided with an iron cylinder 6, and a foam backing plate 4 fixed with a wooden backing plate 5 is provided below the iron cylinder 6; a wide-mouth thermos 8 is fixed in the iron cylinder 6, and the thermos 8 has a The mouth is provided with a polystyrene foam cover 9; the temperature probe I10, temperature probe II11, temperature probe III12, and temperature probe IV13 are respectively inserted on the foam plastic cover 9. The temperature probe I10, temperature probe II11, temperature probe III12, and temperature probe IV13 is respectively connected with the temperature recorder 3, and is used for recording the temperature change curve of the slurry in the thermos bottle 8, the air, and the triglyceri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com